20 tilt alarm switch (prior to s/n 0300065534), Manual adjustment, 21 spark arrester cleaning instructions – JLG 800A_AJ ANSI Service Manual User Manual

Page 142: Tilt alarm switch (prior to s/n 0300065534) -86, Manual adjustment -86, Spark arrester cleaning instructions -86, Tilt switch adjustment -86, Coupling port information table -86

SECTION 3 - CHASSIS & TURNTABLE

3-86

– JLG Lift –

3120740

3.20 TILT ALARM SWITCH (PRIOR TO S/N

0300065534)

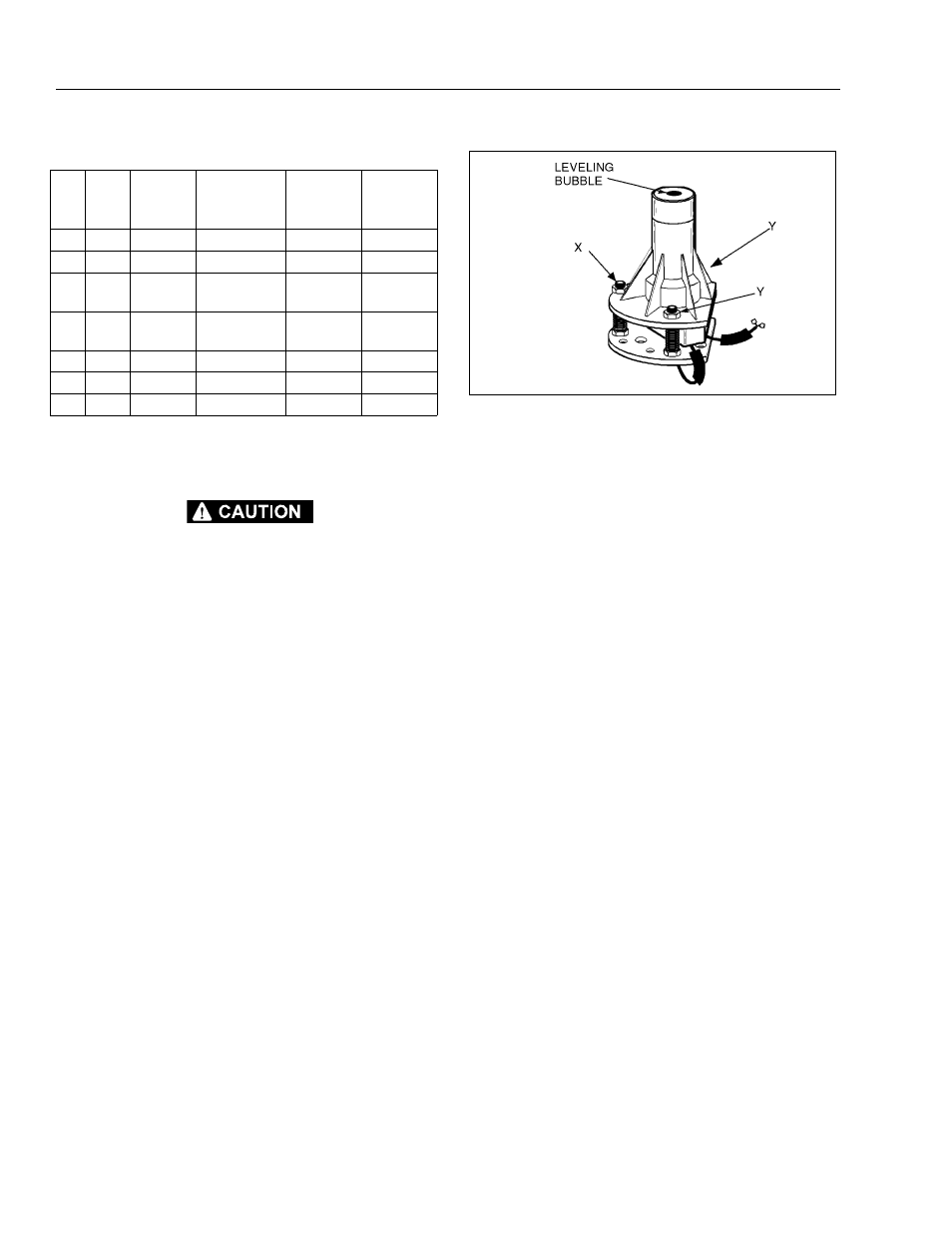

PERFORM TILT ALARM SWITCH LEVELING PROCEDURE A MINI-

MUM OF EVERY SIX MONTHS TO ENSURE PROPER OPERATION

AND ADJUSTMENT OF SWITCH.

Manual Adjustment

1. Park the machine on a flat, level surface. Ensure

machine is level and tires are filled to rated pressure.

NOTE: Ensure switch mounting bracket is level and securely

attached.

2. Level the base of the indicator by tightening the

three flange nuts through approximately one quarter

of its spring travel. DO NOT ADJUST THE “X” NUT

DURING THE REMAINDER OF THE PROCEDURE.

3. With the electrical connections complete, using bub-

ble level on top of indicator, slowly tighten or loosen

the three flange nuts until indicator is level.

4. Individually push down on one corner at a time;

there should be enough travel to cause the switch to

trip. If the switch does not trip in all three tests, the

flange nuts have been tightened too far. Loosen the

“X” nut and repeat steps (2) through (4) LIMIT

SWITCHES ADJUSTMENTS.

3.21 SPARK ARRESTER CLEANING

INSTRUCTIONS

1. Remove the cleanout plug in the bottom of spark

arrester (muffler).

2. Without causing deformation (or any type of dam-

age to the spark arrester) repeatedly tap on the

arrester near the cleanout plug. This may be enough

to begin drainage of the spark trap.

3. An industrial vacuum cleaner can do a complete job

at this point.

a. Or, IN A SAFE AREA, start the engine. Then

alternate between low idle and high idle for two

to three minutes.

b. Or, operate the engine as required by the appli-

cation for two to three minutes.

4. Install the cleanout plug.

Table 3-9. Coupling Port Information Table

Port

No.

Outlets

Port Size

Description

Operating

Pressure

PSI (Bar)

Proof

Pressure

PSI (Bar)

1

2

-6

Brake

450 (31)

675 (46.5)

2

2

-6

2 Speed

4500 (310) 6750 (465)

3

1

-6

Steer

2500 (138)

3750

(258.5)

4

1

-6

Steer

2500 (172)

3750

(258.5)

5

3

2-16, 1-6

Drive Reverse

4500 (310) 6750 (465)

6

1

-16

Drive Forward

4500 (310) 6750 (465)

7

2

-12

Drain

250 (17)

375 (26)

Figure 3-50. Tilt Switch Adjustment.