Advance Adapters 477023 User Manual

Page 10

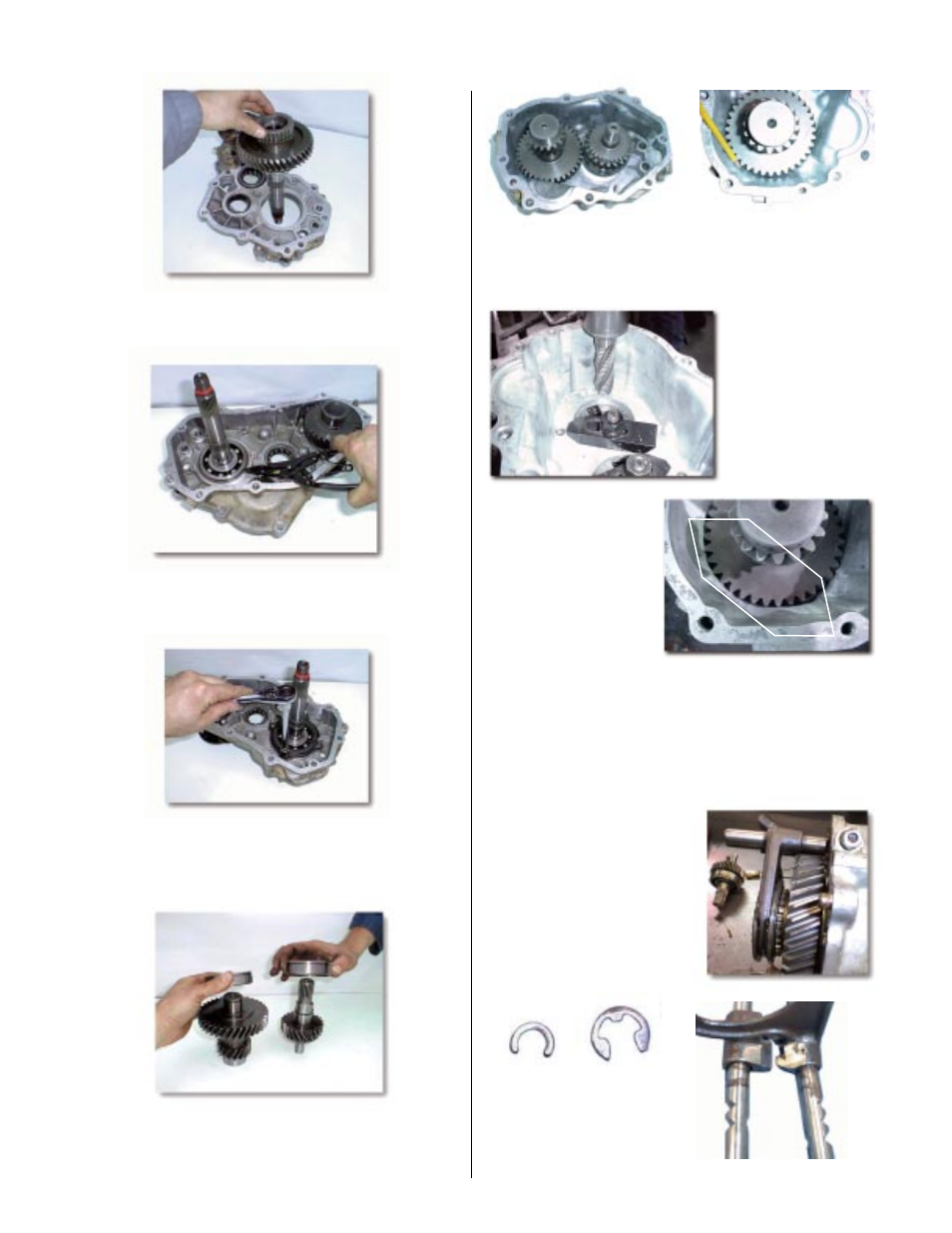

(Step A-12)

(12) If your case uses the large E-clip, remove and replace with

the new C-clip (supplied in kit).

See Photo A-12a

. The shift

fork/rail assembly should be test fit before proceeding with

the assembly. Some grinding on the fork rail boss may be

required to clear the larger gear. See

Photo A-12b

for

grinding locations.

As a final check, reinstall shift

rails/fork assembly over new

gear and temporarily install

mating case so that the shift

rails are indexed into the case.

The gear should rotate easily

with no interference. Now re-

move case half and go on to

Step 13.

Photo A-12a

Photo A-12b

r

New style

C-clip

supplied.

r

Discard this

E-clip.

(Step A-7)

(7) Install the output shaft assembly into the case. You might

have to tap it in gently with a soft plactic hammer.

(Step A-8)

(8) Install a new snap ring (provided in the kit) that holds in the

bearing for the output shaft.

(Step A-9)

(9) Install the bearing retainer into its original position. Apply

Loctite 242 and install the 4 bolts removed earlier. Torque

evenly to 13 ft./lbs.

(Step A-10)

(10) Press on the cluster / counter gear and input gear bearings.

Be sure to install new snap rings that retain the bearings

on the shafts.

(Step A-11)

(11) Install the cluster and input gears into the reduction case.

A slight tap from a soft plastic hammer should be all it takes to

get them seated. Note: On the 4.77 & 5.0 gears, the case must

be machined to provide

clearance for the clus-

ter gear. On some 4.0

cluster gears, we have

found that the case will

need to be relieved due

to core shift. Spin the

cluster gear to check for

interference.

4.77 cluster interference

You can grind the necessary

clearance; however, it is rec-

ommended to machine the

case for this clearance. We

used a 1” coarse pitch

roughing end mill and took

approximately .050” off the

inside case wall. (We also

offer a new front housing that

has the proper gear clear-

ance,

P/N 51-5911

)