Aerovent ES-2-06 User Manual

Page 5

Twin City Fan Companies Engineering Supplement 2-06

5

10. Mount drives as follows:

a. Slip (do not pound) proper sheave onto cor-

responding shaft. CAUTION: PLACING FAN

SHEAVE ON MOTOR CAN OVERSPEED WHEEL

AND CAUSE STRUCTURAL FAILURE.

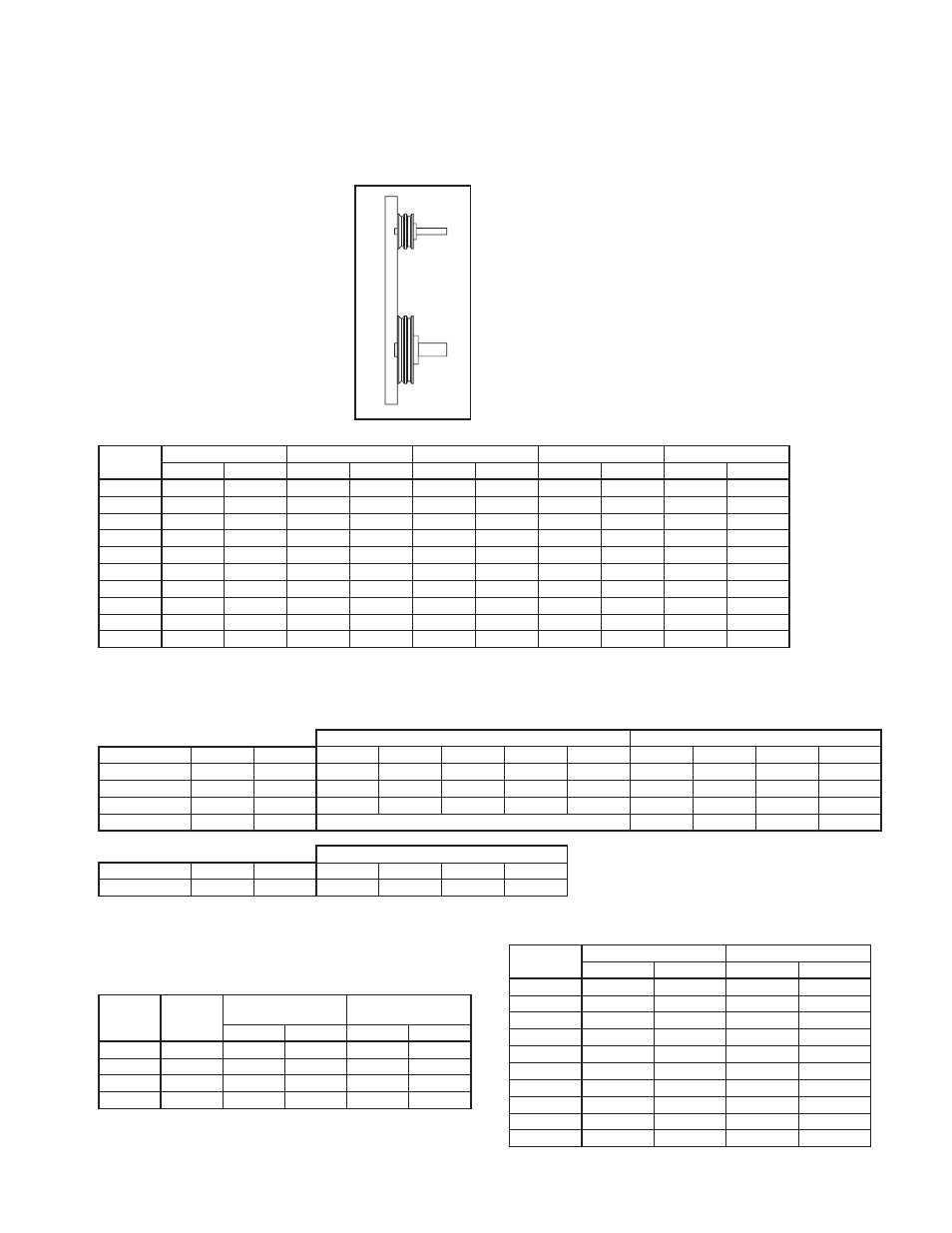

b. Align sheaves with a straight-

edge extended along the

perimeters of both sheaves,

just making contact in two

places on outside perimeters

of both sheaves (see Figure

5). Parallel alignment should

be within 5mm per meter

of center distance. Angular

Misalignment should be less

than 1 degree.

c. Tighten down sheave bolts.

d. Install a matched set of

belts. Adjust belt tension as

indicated in “Drive Mounting”

step #3.

Size

Grade 2

Grade 5

Grade 8

Aluminum

Stainless

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

1/4 - 20

5.5

7.5

8

10.8

12

16.3

3.8

5.2

6.3

8.5

5/16 - 18

11

15

17

23

25

34

6.7

9.1

11

15

3/8 - 16

22

30

30

41

45

61

11.9

16

19

26

7/16 - 14

30

41

50

68

70

95

19

26

31

42

1/2 - 13

55

75

75

102

110

149

26

35

43

58

5/8 - 11

100

136

150

203

220

298

59

80

92

125

3/4 - 10

170

230

270

366

380

515

81

110

128

174

7/8 - 9

165

224

430

583

600

813

125

169

194

263

1 - 8

250

339

645

874

900

1220

184

249

287

389

1 1/4 - 7

500

678

1120

1518

1500

2034

336

456

523

709

e. Tighten belts to proper belt tension. Record the

belt tension used. See drive mounting section for

tensioning instructions. Proper tension is specified

in the datasheet included with the fan.

11. Fans that have motors and drives mounted at the

factory are trim balanced prior to shipment. This

is not possible on units that are shipped without

motors and drives. The addition of drive compo-

nents in the field can create unbalance forces. Twin

City Companies, Ltd. recommends final balancing

of the unit after the drive components are installed.

Failure to do so voids the Twin City Fan Companies,

Ltd. warranty.

12. Repeat the installation checks indicated for factory

assembled units to assure proper tightness and

alignment of all components.

Bearing Installation

Bearings are only to be field installed when accompa-

nied by installation instructions from the bearing manu-

facturer. When field installation is required, follow the

manufactures instructions carefully to install bearings.

Table 1. Bolt Tightening Torque

METRIC SHAFTS

SET SCREW SIZE

LOCKING COLAR SCREW SIZE

Manufacturer

BRG ID

Units

M5

M6

M8

M10

M12

M4

M5

M6

M8

Dodge

S2000

N-m

-

-

17.8

35

57

-

-

-

-

Dodge

SCAH

N-m

3.4

6.9

16

28

51

5.85

10.75

20.5

45

Dodge

SCMAH

N-m

3.4

6.9

16

28

51

5.85

10.75

20.5

45

SKF

SY

N-m

See Below

4.2

7.4

Table 2b. Metric Set Screw Torque Specifications

BEARING DIAMETER

Manufacturer

BRG ID

Units

12-35mm 40-45mm 50-65mm

70-100mm

SKF

SY

N-m

4

6.5

16.5

28.5

Table 2a. Bearing Cap Bolt Torque Specifications (see page 6)

Bolt

Size

Bushing

Type

Iron/Steel Hub,

Sheave

Aluminum

Hub

Ft - lbs

N - m

Ft - lbs

N - m

1/4 - 20

H

8

11

8

11

5/16 - 18

P, B

17

23

13

18

3/8 - 16

Q, R

30

41

24

33

1/2 - 13

S

70

95

-

-

Table 3. Browning Split Taper Bushing Tightening Torque

Table 2c. IP Set Screw Torque Specifications (see page 7)

Set Screw

Size

Steel Set Screws

Stainless Set Screws

Ft - lbs

N - m

Ft - lbs

N - m

1/4 - 20

5.5

7.5

5.8

7.9

5/16 - 18

11

15

11

15

3/8 - 16

22

30

19

26

7/16 - 14

30

41

28

38

1/2 - 13

55

75

42

57

5/8 - 11

100

136

82

111

3/4 - 10

170

230

115

156

7/8 - 9

165

224

-

-

1 - 8

250

339

-

-

1 1/4 - 7

500

678

-

-

Table 4. Set Screw Tightening Torque (other than bearing set screws)

Figure 5.

Sheave Alignment