Aerovent ES-2-06 User Manual

Page 12

12

Twin City Fan Companies Engineering Supplement 2-06

Operation Checklist

M

Verify that proper safety precautions have been followed.

M Electrical power must be locked off.

Check fan mechanism components:

M Nuts, bolts, setscrews are tight per Tables 1 - 4.

M

Mounting connections are properly made and tightened.

M Bearings are properly lubricated.

M

Wheel, drives and fan surfaces are clean and tightened.

M Rotating assembly turns freely and does not rub.

M Drives on correct shafts, properly aligned, and prop-

erly tensioned.

M Check that no foreign objects are in the fan or

ductwork.

Check fan electrical components:

M Motor is wired for proper supply voltage.

M

Motor was properly sized for power of rotating assembly.

M Motor is properly grounded.

M All leads are properly insulated.

M Resistance between motor windings and earth is over

10 megohms (see motor maintenance section).

M Control equipment is functioning properly.

Trial “bump”:

M Turn on power just long enough to start assembly

rotating.

M Check rotation for agreement with rotation arrow.

M Listen for any unusual noise.

Run unit up to speed:

M Bearing temperatures are acceptable (<200°F, 93°C)

after one to two hours of operation.

M Check for excess levels of vibration. Filter in readings

should be 7.2 mm/s RMS or less.

M Check that motor current draw is not above the

nameplate value.

After one week of operation:

M Check all nuts, bolts and setscrews and tighten if

necessary.

M Readjust drive tension if necessary. (See Table 5 for

drive maintenance schedule.)

Optional Accessories

1.

Turning Gear — A turning gear is sometimes used

in high temperature applications where the fan is

exposed to high temperature gases while not operat-

ing. The wheel and shaft can expand unevenly due

to the temperature when sitting idle, which can cause

vibration at startup and/or a permanent set to the

rotor. The turning gear slowly turns the fan from the

outboard side while it is not operating, providing for

even thermal expansion. It starts automatically when

the fan shuts down and disengages automatically

when the fan starts up again. More specific informa-

tion will be provided for each application.

2.

Shaft Seals — The standard shaft seal is a ceramic

fiber element retained with an aluminum retaining

plate and clips. Other configurations of shaft seals

are available for special applications, such as when it

is necessary to keep the shaft seal as gas tight as

possible. Shaft seal application manuals are provided

in Engineering Supplement ES-595.

3.

Variable Inlet Vanes — Variable inlet vanes are pro-

vided as assemblies internally in the inlet cone or

externally in a flanged cylinder. The vanes are used to

control volume and save power in installations where

different volumetric operating conditions are used.

Installation manuals are provided in other engineer-

ing supplements for specific fan types. Variable inlet

vanes may be provided with powered operators in

which case the manufacturer’s installation and operat-

ing manuals will be provided.

4.

Inlet Box and Inlet Box Dampers — Inlet boxes may

be provided to allow transition from a duct to the

fan inlet. Inlet box dampers may also be provided for

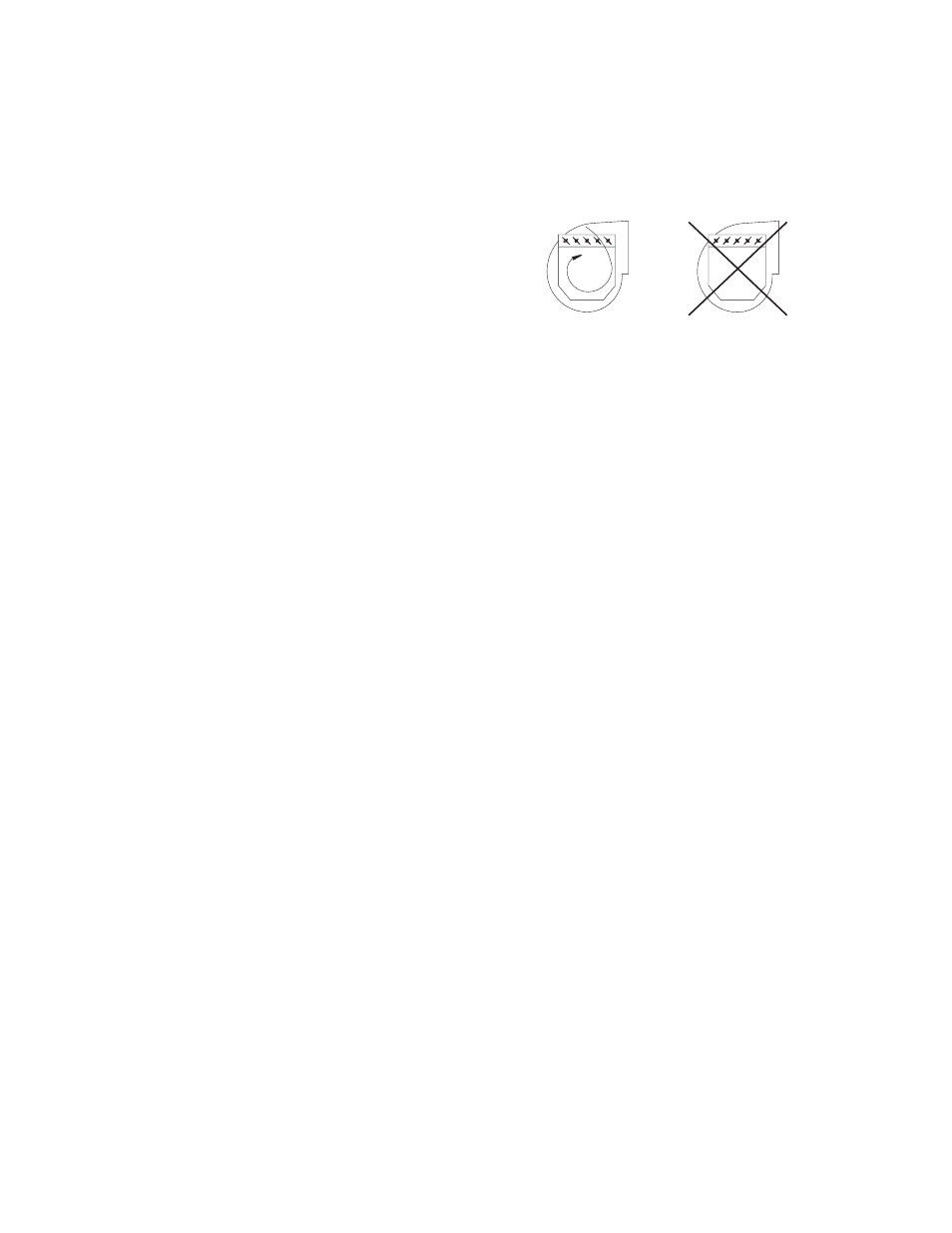

volumetric regulation similar to inlet vanes. Dampers

are usually provided as a complete assembly and are

installed with the damper axles parallel to the fan

shaft. They should be installed to pre-spin the air in

the direction of fan rotation. See Figure 7.

5.

Outlet Dampers — Outlet dampers are usually provided

completely assembled like the inlet dampers. The damp-

er is bolted to the fan discharge for volume control.

6.

Shaft Cooler — Also referred to as “heat slingers”

or “cooling wheels,” these are small, radially bladed

aluminum wheels that are split and bolted for instal-

lation between the inboard bearing and fan housing.

The backplate usually is closest to the fan housing

and the blades face the bearing. Specific instructions

will be provided by application.

7.

Oil Circulating Systems — Usually the following modi-

fications will have to be made to the bearing if an

oil circulating system is used. When an oil circulat-

ing system is included, a manual for its installation,

operation, and maintenance will accompany it.

a. Four drain holes will be drilled in the bearing, two

on each side of the bearing. Because of this, the

bearing may be drained from either side. (Drain

from both holes on one side of the bearing.)

b. It is not necessary to drain the bearing.

c. The bearing will be packed with grease to prevent

corrosion until installed and started up. The drain

holes will be plugged with plastic covers to make sure

they are open.

The customer MUST REMOVE most

of the grease using solvent and remove the plastic

covers prior to starting the oil circulating system.

d. A wet sump will be added in case of circulating

oil pump failure. Seals will be provided to accom-

modate the resultant splashing.

e. The zerk on top of the bearing will be removed

for that hole to be used as the oil inlet.

Troubleshooting Guidelines

Use current safety practices when investigating fan or

system performance problems. General safe practices

and performance troubleshooting guidelines can be

found in AMCA Publications 410 and 202, respectively.

Fan application and field measurement procedures can

be found in AMCA Publications 201 and 203.

Below is a list of possible areas to check when air

or sound values do not match expectations. Most fan

problems can be pinpointed to one of these common

causes.

RIGHT

WRONG

Figure 7. Orientation of Damper Blades As Related to Fan Rotation