Aerovent ES-2-06 User Manual

Page 15

Twin City Fan Companies Engineering Supplement 2-06

15

5

4

3

Tool AS-14093

Blade Tip

Cheater Bar

Hub

Blade

Leading Edge

Detail "X"

Blade

Trailing Edge

Detail “X”

Vernier Index Line

(Blade As Shown

Is Adjusted To 35°

)

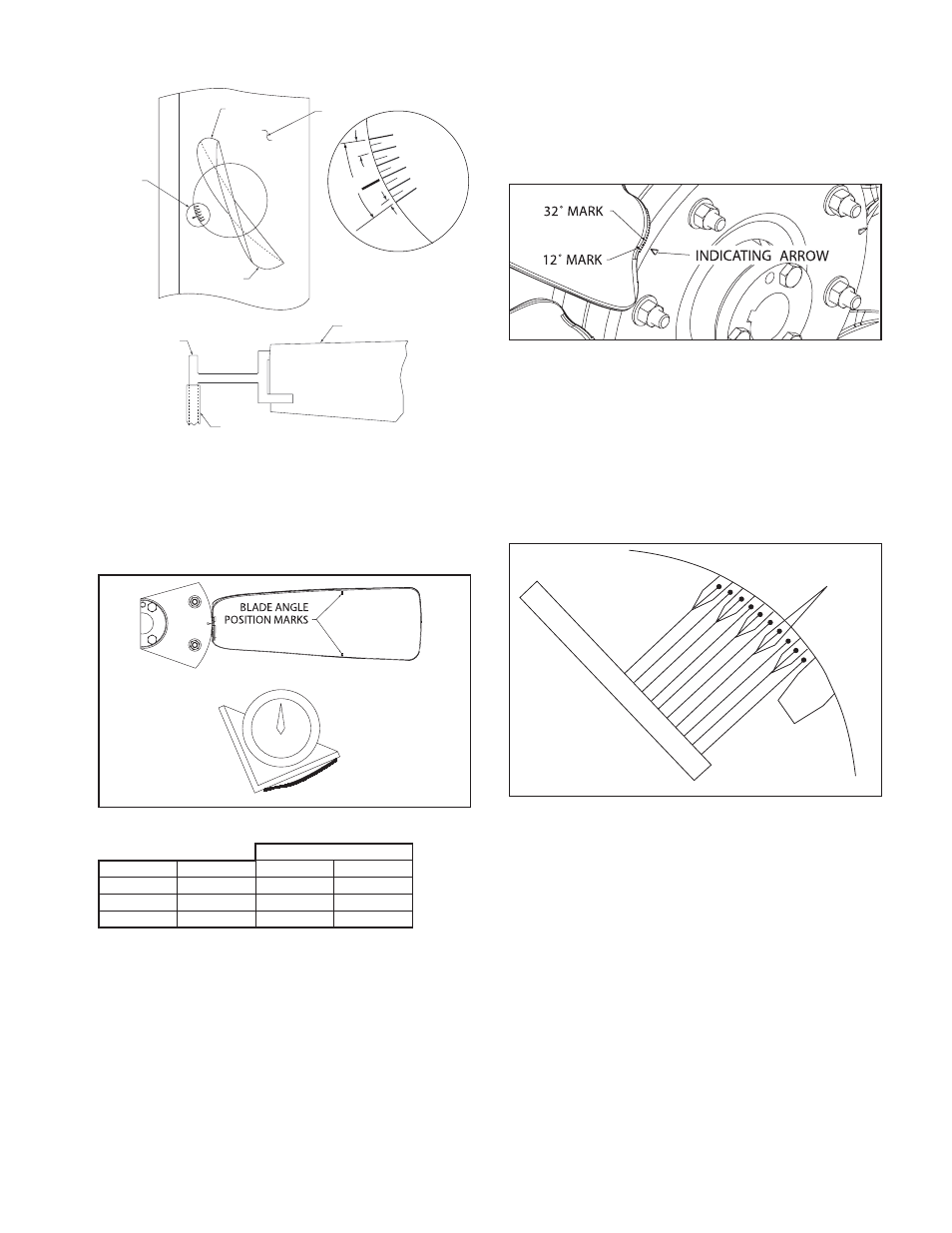

Figure 10. TCVX Blade Angle Adjustment

25.0"

5.0"

2.5"

5

4

3

Blade

Hub

6. Re-tighten the blade retaining bolts to the torque

shown in Table 7. Work in a star pattern, working your

way up to the desired torque in steps. Tightening one

bolt to the full torque before moving on to the next

can crack the hub.

Alternate Method

1. Loosen the blade retaining bolts until they are finger-

tight. At this point, the blades should rotate in their

sockets when grasped firmly and twisted, but not turn

on their own.

2. Angle setting marks on the blade line up with an indi-

cating arrow on the hub. There are two long marks

on the blade, one for 12° blade angle and another for

32°. Shorter indicating marks at 5° increments are in

between the two longer marks. See Figure 12.

Figure 11. Blade Position Marks

Blade Bolt Torque

Fan Size

Hub Size

Ft - lb

N - m

14 - 24

6

17

23

30 - 36

9

30

41

42 - 48

12

75

102

See Table 3 for bushing bolt torques - Use aluminum hub values.

Table 7. "E" Prop Torque Specifications

3. Twist each blade to the desired blade angle.

4. Re-tighten the blade retaining bolts to the torque

shown in Table 7. Work in a star pattern, working your

way up to the desired torque in steps. Tightening one

bolt to the full torque before moving on to the next

can crack the hub.

Blade Adjustment on Axiad Adjustable Pitch

Propeller

Each blade has cast into it a number of raised marks

with grooves in between and the fairing has a register

mark machined into it at each blade opening. See Figure

13, which identifies each of the ridges and grooves with

a number from 0 to 9. These numbers correspond to the

performance curve numbers shown in the AXIAD II design

performance manual.

On Arrangement 4 Type 3 Axiad fans, the blade angle

can be adjusted by removing the inlet screen. On ducted

fans, the case is provided with an 8-inch square door

in the fan tube. To set the blade pitch, proceed as fol-

lows:

NOTE: A 5/16” key with a square drive adaptor fitted to

a torque wrench is required. In most cases, a universal

joint will also be needed.

1. After access has been obtained to the rotor, loosen the

two blade bolts until the blade is free to rotate.

2. Rotate the blade to line up the register mark on

the fairing with the desired blade angle mark on the

blade.

CAUTION: Do not exceed blade position 9.

3. Tighten the two bolts evenly until a torque level of 65

ft-lb (88 N-m) is reached.

CAUTION: It is important that the blade bolts are

torqued to the specified value. Do not hand-tighten the

bolts.

Figure 13. Axiad Blade Angle Indicators

INDEX ON

HUB

BL

AD

E

PO

SIT

IO

NS

9

8

7

6

5

4

3

2

1

0

Figure 12. "E" Prop Blade Angle Indicating Marks