Aerovent ES-2-06 User Manual

Page 13

Twin City Fan Companies Engineering Supplement 2-06

13

Air Capacity Problems

1. Resistance of the system is not at design rating. If

resistance is lower than expected, both airflow and

horsepower may be up. If resistance is higher than

anticipated, air volume will be down.

2. Fan speed is not at design speed.

3. Air density is not at the design value. Also check air

performance measurement techniques/procedures.

4. Devices for air modulation are closed or plugged.

Also check filters.

5. Wheel mounted improperly or is rotating in reverse.

6. Parts of the system or fan have been damaged or

need cleaning.

Noise Problems

1. Air performance is incorrect and the fan is not at

design point of operation. Fan is being forced to

operate in an unstable flow region.

2. Bearing failure. Check bearings (lubrication).

3. Supply voltage high or inconsistent supply frequency.

Adjustable frequency controllers can generate motor

noise.

4. Objects that are installed in a high velocity airstream

can generate noise. This includes flow sensors, turn-

ing vanes, etc.

5. Poor fan inlet conditions.

6. Acoustics or sound measurement procedure incorrect.

Vibration Problems

1. Misalignment of drive components.

2. Poor foundation or mounting structure (resonances).

3. Foreign material attached to rotating components.

4. Damaged rotating components (bearings, shaft, fan,

wheel, sheaves).

5. Broken, loose or missing setscrews.

6. Loose bolts.

7. Vibration transmitted by another source.

8. Water accumulating in airfoil blades.

9. Fan is operating in stall or unstable flow region.

Motor Problems

1. Incorrect wiring.

2. Speed of fan too high.

3. Parts improperly installed; binding.

4. Bearings improperly lubricated.

5. WR

2

capability of motor too low for application.

6. Protection devices may be improperly sized.

Drive Problems

1. Belts improperly tensioned.

2. Drive alignment is poor.

Disposal

All metal and other recyclable materials should be

separated and properly recycled. Paint, insulation, plastic,

packaging materials, lubricants, electrical components

and other items should be disposed of per local

regulations.

Handling

Roof ventilators should be lifted by using straps around

the fan housing or base only. Spreader bars should also

be used to avoid damage to stack caps or hoods. DO

NOT LIFT ROOF VENTILATORS BY THE STACK CAP

OR HOOD. On hooded units, disassemble the stack

from hood when lifting. Upblast models may be lifted

assembled.

Installation Instructions – Follow the above section

titled “Fan Installation, Factory Assembled Units” with

the exception of the instructions below for commercial

ventilators.

Roof ventilators should always be mounted to a flat,

level, solid and rigid structure. Particular caution should

be exercised when installing fans on metal buildings. Be

sure wall or roof is capable of supporting the fan(s). Fans

mounted on walls or roofs and not supported correctly

will cause vibration that could cause damage or injury.

Fans mounted off ground level should be rigidly

mounted to a structural platform and be placed over or

as near as possible to a solid wall or column.

Support for suspended fans must be cross-braced for

live load support to prevent side sway. Use guy wires

to help secure roof units if excessively windy conditions

prevail.

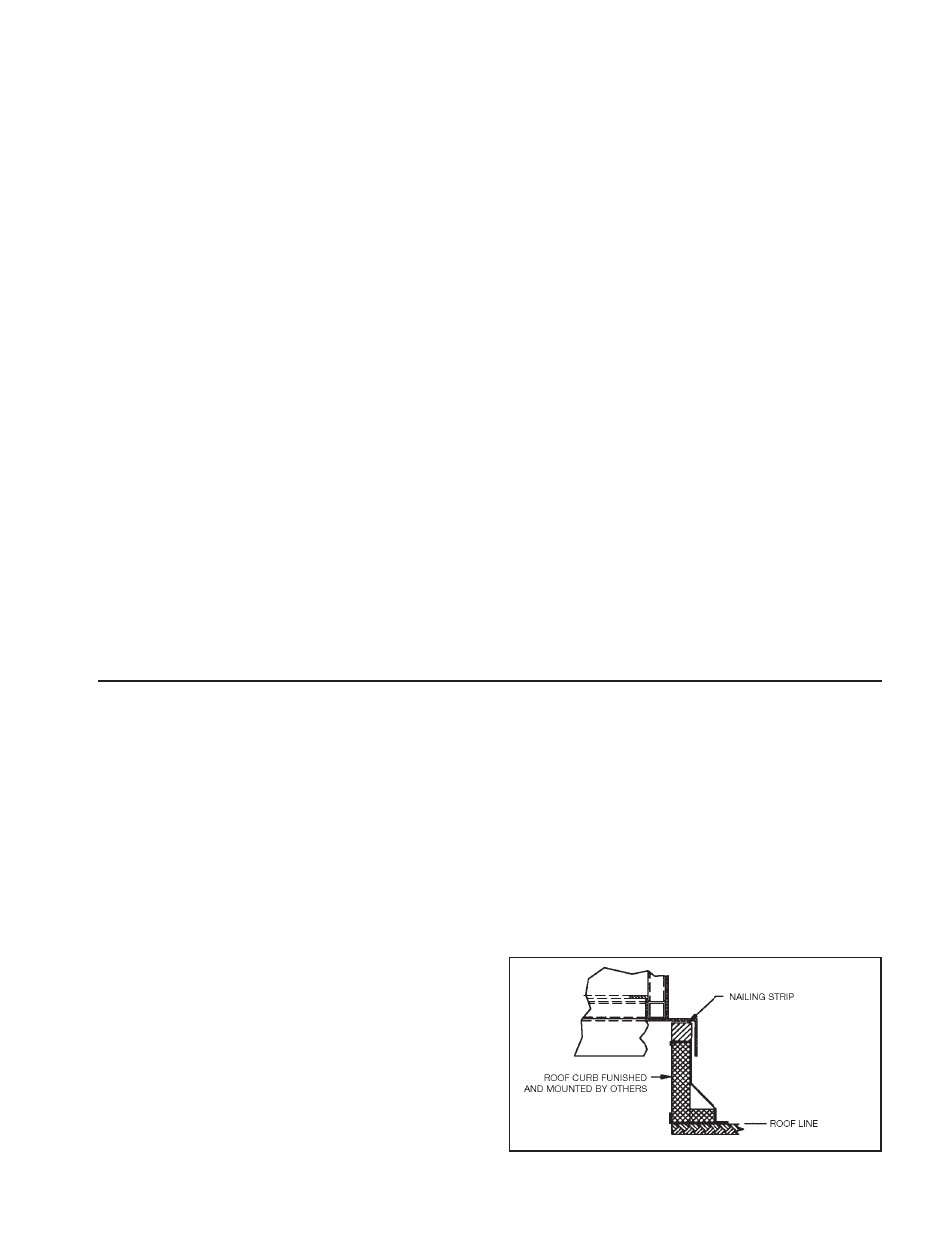

Appendix A – Commercial Ventilator Installation instructions

When the roof ventilator is designed to be mounted

on a curb, the curb should be securely installed prior to

the fan installation.

A damper, if used, should be securely mounted within

the curb or wall in a manner which allows free and

unobstructed operation.

On roof units, anchor the fan securely to the curb.

Anchoring through the vertical portion of the curb cap

flange is recommended. Use a minimum of four lag bolts

or other suitable fasteners. See Fig 8 below.

Figure 8. Mounting Roof Ventilator to Curb Cap