Appendix b – axial fans – Aerovent ES-2-06 User Manual

Page 14

14

Twin City Fan Companies Engineering Supplement 2-06

Axial Fans - Securing the Wheel to the Shaft

If the propeller is removed for any reason, make sure that

it is securely attached to the shaft before restarting the

fan. If the propeller is attached to the shaft by means of

a Trantorque bushing, use the tightening torque values

shown in Table 6 below. For other bushings, see table 3

for proper torque values.

Axial Fans with Adjustable Blade Angles

The blades are set at the factory to the blade angle that

gives the performance specified on the order. This angle

should be checked prior to start-up. The blade angle

should not be changed from that stated for the order

without assuring that a change in blade angle will not

overload the motor, any controls, or other items. Vibration

levels shall also be checked in accordance with ISO

14694:2003, “Industrial Fans – Specifications for Balance

Quality and Vibration Levels” if any change is made to

blade angles.

Appendix B – Axial Fans

Blade Adjustment on Adjustable Pitch Vaneaxial

Type TCVX

The patented wheel construction uses friction and cen-

trifugal force to hold the blades in place. No disassembly

of the wheel is required to change the blade angles. If

it is necessary to change the blade angle, the following

procedure should be used:

1. Work safely. Make sure that proper safety precautions

have been followed. Electrical power must be locked

off.

2. The adjustment can be made through the inlet on open

inlet fans. On fans with ducted inlets, open the wheel

area access door.

3. Place adjustment tool around end of blade (see Figure

10). If necessary, apply “cheater bar” around the 11/4"

(31.75mm) diameter end for additional leverage. The

blades can be turned by hand on open inlet fans. If

additional leverage is needed, place a wrench on the

leading edge of the blade near the hub. Take care not

to mar the surface of the blade.

Blade Adjustment on Type "E" Adjustable Pitch

Propeller

Preferred Method (more Accurate)

1. Lay the hub on a horizontal surface with the concave

(air leaving) surfaces of the blades facing upwards.

2. Loosen the blade retaining bolts until they are finger-

tight. At this point, the blades should rotate in their

sockets when grasped firmly and twisted, but not turn

on their own.

3. Place an angle meter across the two blade angle posi-

tion marks on a blade. See Figure 11.

4. Twist the blade to the desired blade angle.

5. Repeat steps 3 and 4 for the remaining blades.

Trantorque

Size

Shaft

Diameter

Socket

Size

Torque

Ft-Lb

N-m

7/8

7/8

1-1/2

71

96

1-1/8

1-1/8

1-3/4

130

176

1-3/8

1-3/8

2

141

191

1-5/8

1-5/8

2-1/4

233

316

1-7/8

1-7/8

2-1/2

325

441

2-1/8

2-1/8

2-3/4

440

597

2-3/8

2-3/8

3

470

637

2-7/8

2-7/8

3-1/2

550

746

Table 6. Trantorque Bushing Torque Values

Note: These torque values are to be obtained with a calibrated

torque wrench. DO NOT apply any lubricant to any part of the

Trantorque

®

hub. DO NOT use an anaerobic thread adhesive

such as Loctite

®

on the threads.

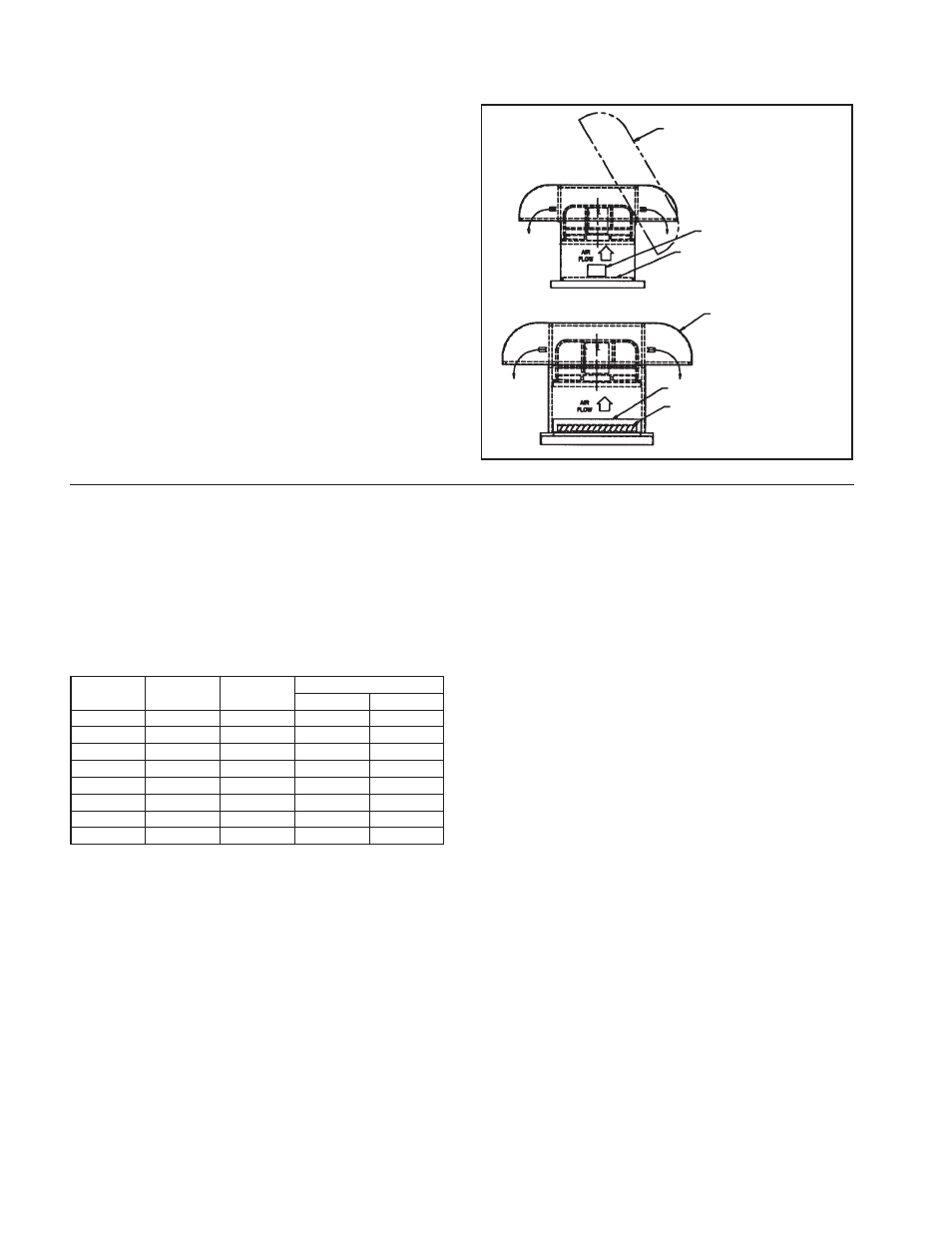

Figure 9. Typical Hooded Roof Ventilator Installations

HINGED HOOD

BOLTED HOOD

SIZE 12" – 42" ACCESS

DOOR FOR INSPECTION

SIZE 48" – 60"

ACCESS DOOR FOR DAMPER

REMOVAL

SAFETY SCREEN STANDARD.

OPTIONAL DAMPER NOT SHOWN.

OPTIONAL DAMPER

Appendix A – Commercial Ventilator Installation instructions

(cont'd)

Hooded Ventilators

Hooded units sizes 12 to 42 use a one-piece hinged

hood. To lift the hood, remove the two bolts located

under the mushroom cap and prop the hood up with the

supplied safety rods. Push and lock into place. A screw

is installed at the end of the pin side of the hinge in the

hood angle to prevent accidental removal of the hood. To

close the hood, replace the bolts to lock in place. For

size 48, a one-piece bolted hood connects directly to the

fan stack. To lift the hood off the unit, remove the bolts

located under the mushroom cap. For sizes 54–72, a two-

piece bolted hood connects directly to the fan stack. To

lift the hood off the unit, remove the sheet metal bolts

than connect the right and left sides of the hood and

then remove the bolts located under the mushroom cap.

See Figure 9 below.