Aerovent ES-2-06 User Manual

Page 16

TM

®

4. Repeat steps 1 through 3 for all blades. Make sure all

blades are set at the same mark.

5. After all blades are set at a new angle, run the fan for

a few minutes and then re-torque all blade bolts.

Blade Adjustment on Aerovent Reversible

Adjustable Pitch Propeller

Assembly Procedures

1. Lay hub on a horizontal surface with openings of

shank sockets (Figure 15) facing up. This is normally

the discharge side of the assembly.

2. Lay blade shank in socket with discharge side of the

blade up. The discharge side of the blade is the side

with the angle setting mark. Line up the index mark on

the blade with the proper angle mark on the end of

the shank socket (Figures 14 and 15) on the underside

of assembly.

3. Place cap over blade shank with beveled end toward

center. Install U-bolts and elastic nut stops. Before

tightening lock nuts, pull the blade outward to set

the key against the keyway and check angle setting

(Figures 14 and 15).

4. Tighten elastic stop nuts evenly and torque to the fol-

lowing foot-pounds:

5. Check angle setting to be sure it has not changed

during assembly. If so, loosen lock nuts and reset

angle. Tighten nuts again to proper torque. Do not

over-tighten. Be sure to tighten U-bolts evenly.

Setting Angle with Protractor (optional)

Under most conditions, the preceding assembly proce-

dure using the index marks is of sufficient accuracy.

When greater accuracy is desired, use a level bubble

protractor. Before the final tightening of the nuts, set the

protractor on the angle setting mark. (The hub and blade

assembly must be level for accurate setting.)

Adjust the angle by tapping the shank end with a

mallet.

Tighten lock nuts to proper torque per Table 8. Again

check the angle setting. Rotate propeller to check angle

on each blade in the same location.

Propellers may be assembled so the cap side of the

hub is the inlet side (reverse bore). If blades do not have

the index mark on the discharge side, it is then necessary

to adjust the blade angle with a protractor.

The hub and blades are balanced separately. The

weight distribution throughout the length of the blade

varies slightly. Therefore, the balance is to a constant

moment and blades may be assembled at random even

though the weights are slightly different.

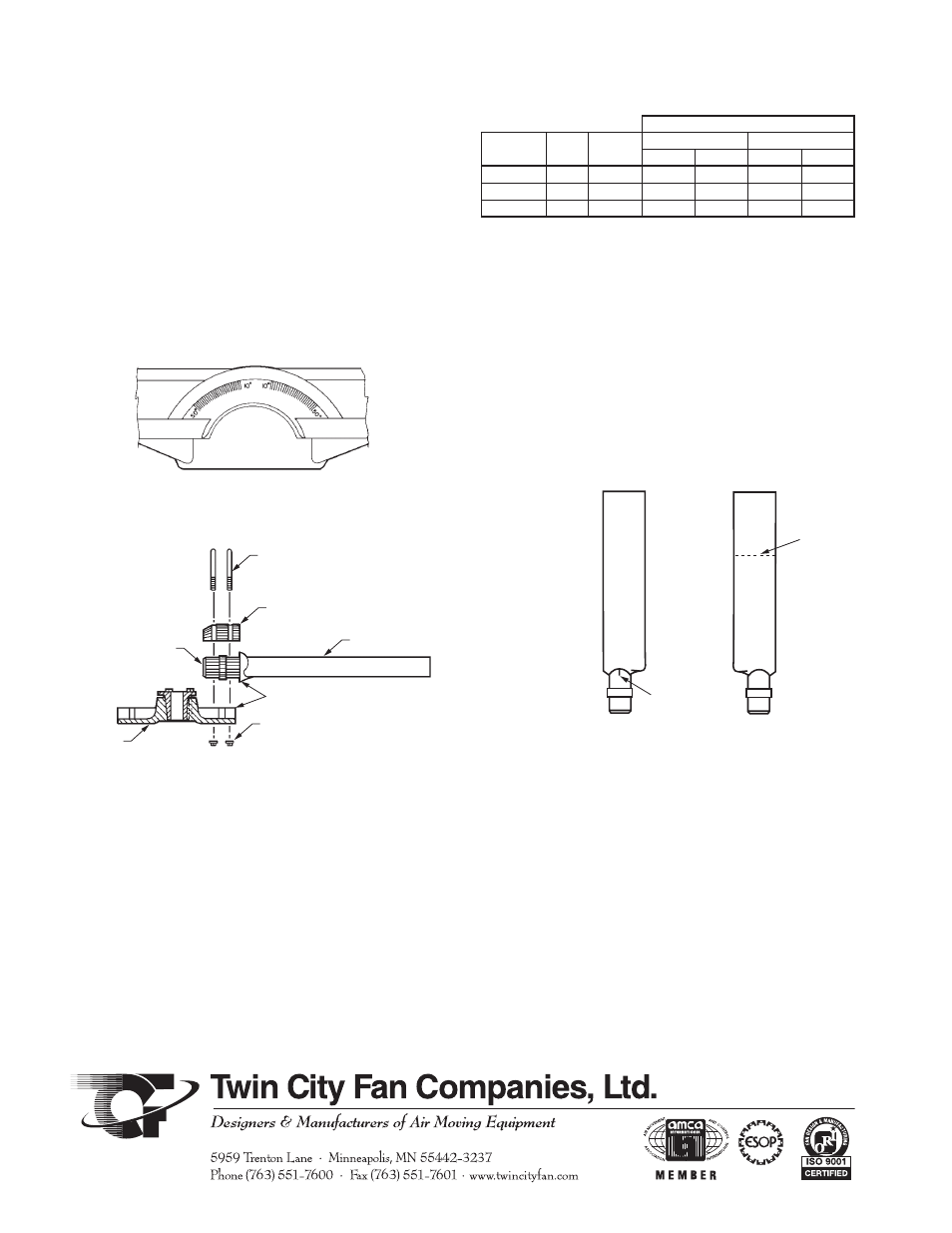

Angle setting index on shank socket. Marked

from 10° through 50°. Each mark is 2°.

Figure 14. Angle Setting Markings

Elastic Stop Nuts

Index Marks

Blade

U-Bolts

Cap

Blade

Shank

Hub

Figure 15. Assembly Exploded View

Angle

Setting

Mark

Index

Mark

Inlet Side

Discharge Side

Figure 16. Blades and Angle Setting Mark

Torque

Prop

Size

Hub

Size

U-Bolt

Size

Aluminum

Fiberglass

Ft-lb

N-m

Ft-lb

N-m

54 - 72

14

1/2”

20

27

30

41

81 - 96

18

3/4”

45

61

50

68

108 - 144

18

3/4”

45

61

50

68

Table 8. U-Bolt Torque for Aerovent Blades