Aerovent ES-2-06 User Manual

Page 11

Twin City Fan Companies Engineering Supplement 2-06

11

All of the above conditions could lead to mechanical fail-

ure causing safety hazards including exposure to ejected

objects and toxic material or vapors.

For high temperature applications, it is recommended

that an auxiliary device be provided (such as a turn-

ing gear available from Twin City Fan Companies, Ltd.)

to slowly rotate the fan when it is not operating while

exposed to high temperatures. Exposure to high tempera-

tures while not operating could be due to a power failure

or standard operation of a process.

When multiple fans are installed for redundancy, the

fan used shall be switched at least weekly to avoid the

need for storage considerations.

Sound

Sound power levels are supplied with each fan. These

levels are based on AMCA 300 reverberant room test

methods. This method is similar to ISO 3741. Field

installation and conditions can affect sound greatly.

Because of this, the user shall verify if the sound pres-

sure levels in the installed condition are below 70 dBA.

If sound pressure levels are above 70 dBA, actions shall

be taken to reduce sound pressure levels to acceptable

levels.

The following EN standards can be referred to as a

guide when making noise measurements:

EN 809 EN ISO 5136:2003 - Acoustics - Determination

of sound power radiated

into a duct by fans and

other air-moving devices

- In-duct method.

EN ISO 11200/A1 1997

- Noise

emitted

by

machinery and equip-

ment - Guidelines for

the use of basic stan-

dards for the determina-

tion of sound pressure

levels at a workstation

and at other specified

positions.

EN ISO 11202/A1 1997

- Noise

emitted

by

machinery and equip-

ment - Measurement of

emission sound pressure

levels at a workstation

and at other speci-

fied positions – Survey

method in situ.

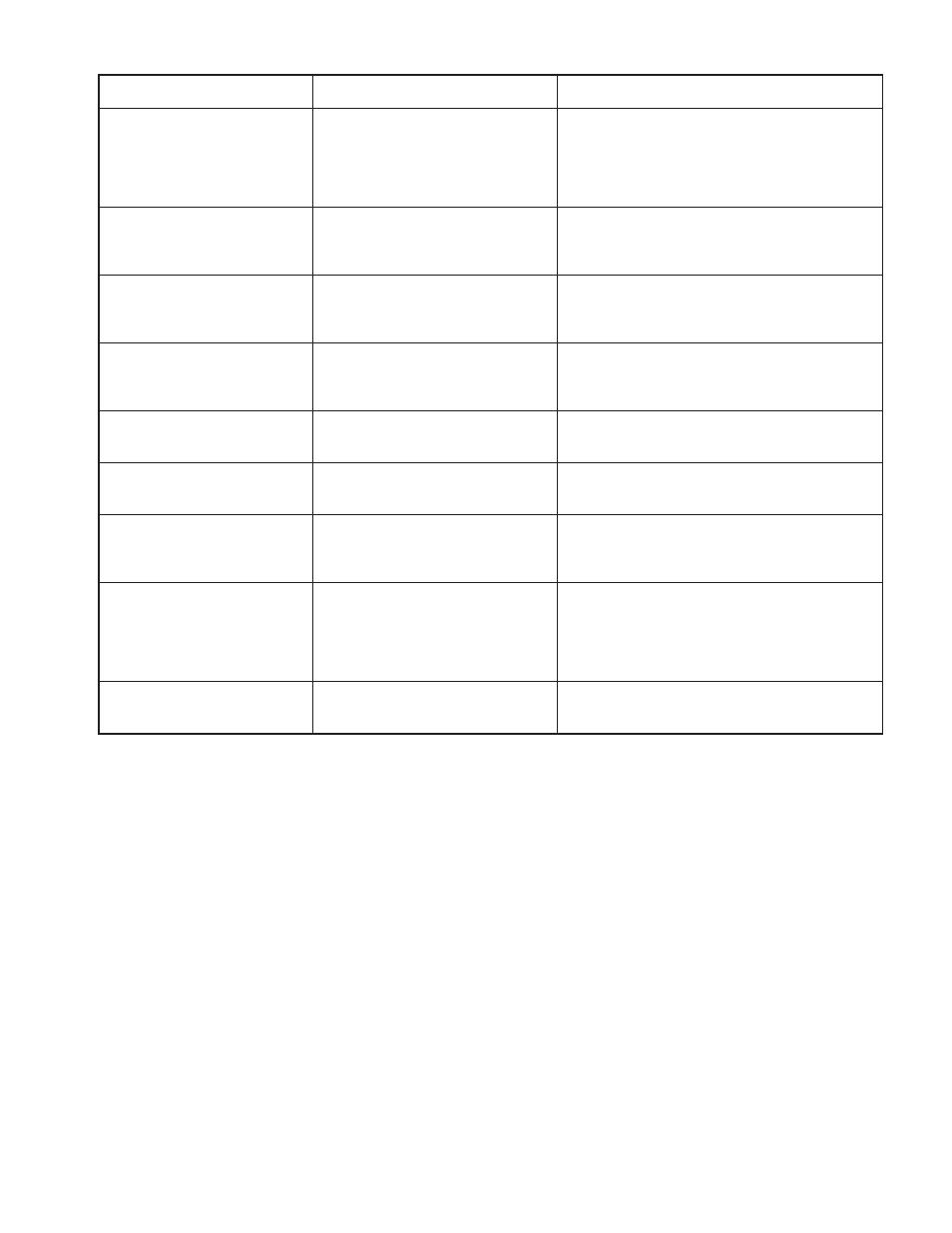

TYPE OF MAINTENANCE

WHEN TO DO

WHAT TO DO

Check for sheave groove wear

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check for belt ride in the groove. In multiple groove

drives, belt ride should be uniform, not more than

1/16" above or below top of sheave groove. Check

groove wear area for wear. Side wall of groove

should be straight, not dished out. Bottom of groove

should show no signs of belt contact.

Check for sheave runout.

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check sheave by eye for runout. If runout is exces-

sive, it can easily be seen by visual inspection. If

runout is noticeable, check sheave for source of

problem and correct.

Inspect for heat build-up and

proper ventilation

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check bolts for heat. Ambient temperature should

not exceed 140°F. Contact temperatures should not

exceed 180°F. Make sure drives are properly ven-

tilated.

Clean belts and sheave grooves

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Inspect belts for contaminates, such as oil or grease.

Wipe belts clean with detergent and water. Inspect

sheave grooves for build-up of such material and

remove, if necessary.

Check belt tension

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check belt tension using BROWNING belt tension

checker. Tension to recommendations shown in cur-

rent catalogs.

Check sheave alignment

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check alignment with straight edge, string or ma-

chinist level. Correct alignment to as near perfect

as possible.

Mismatched belt check

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check belt sag on slack side of drive. All belts

should have a slight bow. If this bow is not uniform

with all belts, replace entire set with a matched

set.

Check for worn belts

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check wear surfaces for belt for excessive wear.

if belts have a slick, glazed look, belts ares lip-

ping. Check drive capacity and belt tension. Never

replace only one belt in a used set, as used belts

will elongate. Replace entire set if replacement is

necessary.

Check sheave setscrews and/or

busing capscrews

Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.

Check all setscrews and/or bushing capscrews for

looseness. Retighten to recommended torque, if ne-

cessary.

Table 5. Drive Maintenance and Inspection