Warning – Snorkel S2633 User Manual

Page 29

Chapter 8 – Prestart Inspection

S2633 – 8210048

25

3. Look for visible cracks in the welds and at the weld

to parent material joints. A bright light may be used

to provide adequate visibility of the inspection area.

Slide Blocks

To inspect the slide blocks:

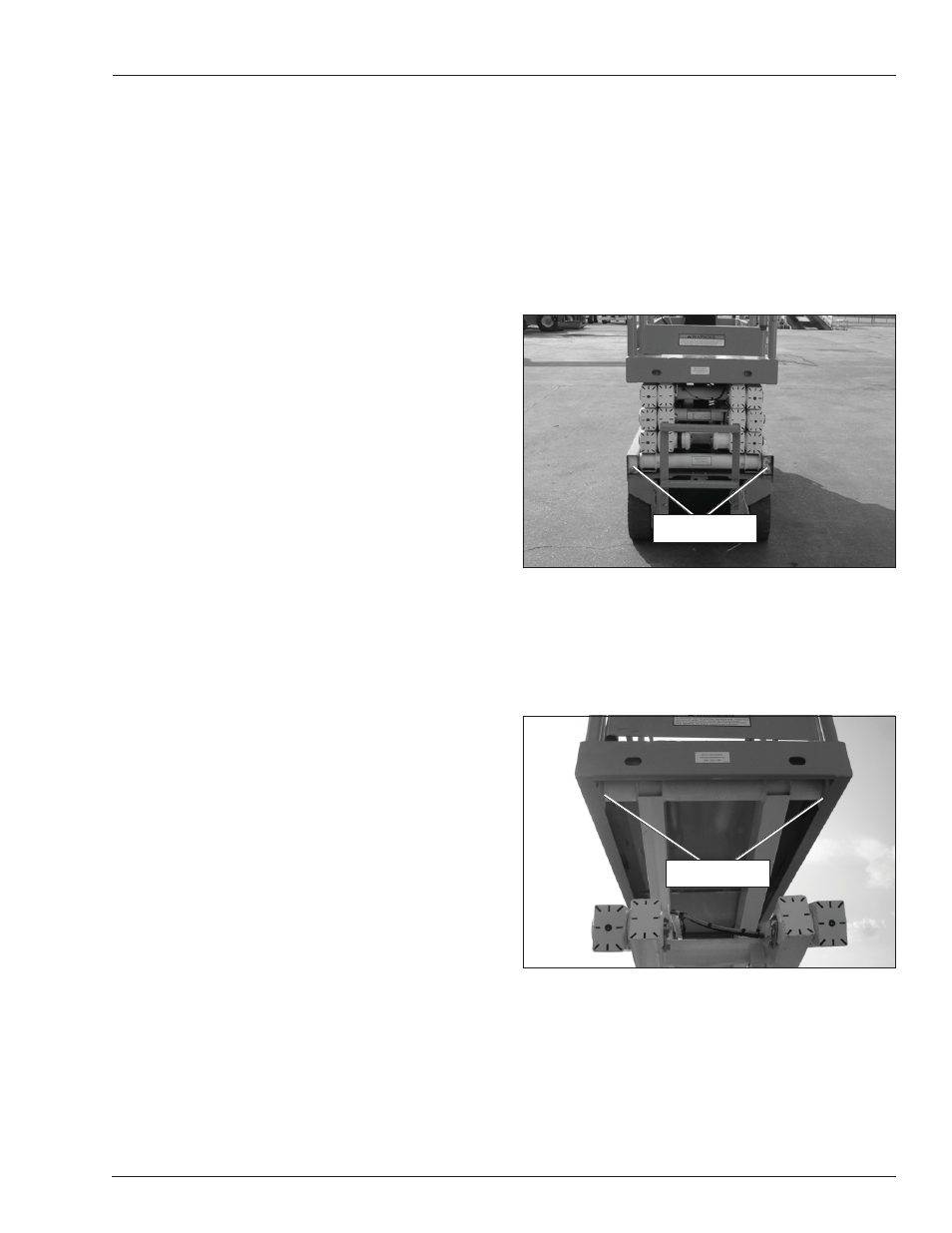

1. Visually inspect the scissors arm slide blocks. They

must be free to move without obstruction. There are

two slide blocks at the rear of the chassis (refer to

Figure 8.10).

Figure 8.10 – Rear of Machine

2. Raise the platform from the lower controls and visually

inspect the slide blocks underneath the rear of the

platform. They must be free to move without obstruc-

tion. There are two slide blocks underneath the rear

of the platform (refer to Figure 8.11).

Figure 8.11 – Rear of Platform

Fasteners

To inspect the fasteners:

1. Visually inspect all fasteners to see that none are

missing or loose.

2. Inspect all of the bolts, nuts, rollpins, collars, and

snap rings. They should all be present, tight, and not

damaged in any way.

Slide Blocks

Slide Blocks

Slide Blocks

Slide Blocks

A

Warning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury could result from such accidents. Fully close

the emergency lowering valve before operating the

aerial platform.

6. Make certain the knob is fully released and the emer-

gency lowering valve is fully closed before operating

the aerial platform.

Lowering Alarm

The machine is equipped with a lowering alarm. Lower

the platform to ensure that the alarm sounds to warn

personnel in the area to stand clear.

All Motion Alarm

The machine may be equipped with an all motion

alarm.

Operate the machine functions to ensure that the alarm

sounds to warn personnel in the area that the aerial

platform is in motion.

Flashing Lights

The machine may be equipped with optional fl ashing

lights mounted on each side of the machine.

To inspect the fl ashing light:

1. At the lower controls, twist the emergency stop button

clockwise and turn the start switch on.

2. At the upper controls, twist the emergency stop button

clockwise.

3. Operate any control function and visually check to

see that the light is fl ashing approximately one fl ash

per second.

Note

There is not an off switch for the fl ashing light.

Structures

Visually inspect all weldments and related components.

It is important to inspect the fasteners that connect the

components.

Weldments

To inspect the weldments:

1. Visually inspect all weldments for abnormal wear,

abrasion, or deformation that could cause interfer-

ence between moving parts.

2. Inspect the welds on the structural components.

Pay particular attention to boom welds. The area to

be inspected should be clean and free of dirt and

grease.