MBW Blitzscreed User Manual

Page 15

13

REPEAT STEPS 6 - 10 UNTIL ENTIRE SCREED IS ASSEMBLED.

After all needed sections are assembled

the edging can be trued horizontally.

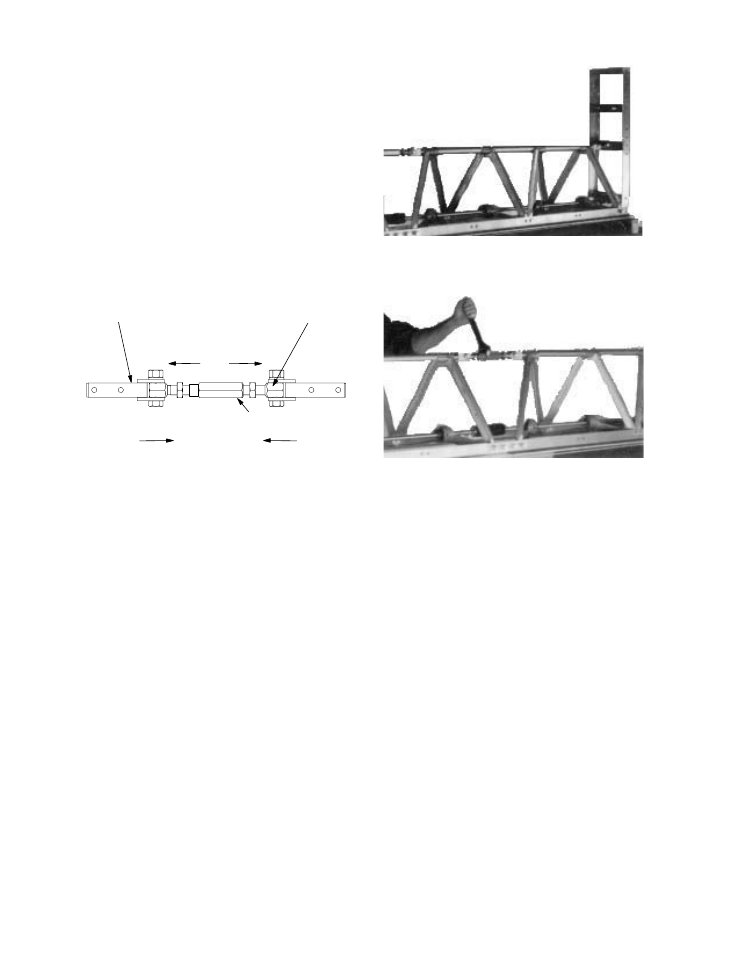

11.If the pour surface is to be crowned or

flat, rotate the turnbuckles so the turnĆ

buckle eyes are pushed away from

each other taking out the slack at the

clevis connections. If the pour surface

is a valley, rotate the turnbuckles so the

turnbuckle eyes are drawn towards

each other taking out the slack at the

clevis connections (see Figure 10).

Tighten down the 5/8 bolts going

through the clevises and turnbuckle

eyes HARD once the slack is removed.

FIGURE 10

Crowned or Flat

Valley

Turnbuckle Eye

Clevis

Turnbuckle

12. The screed is now ready for grade adĆ

justment. Place the assembled screed

on blocks or forms. String a taut chalk

line across the back of the float edge of

the screed (see Figure 11). Start with

the centermost turnbuckle and adjust it

so the bottom edge of the screed

moves up or down until it is adjusted to

the desired grade (see Figure 12). AdĆ

just each turnbuckle, working out from

the center, until the desired grade is

achieved. As the turnbuckles are adĆ

justed from the center out, previously

adjusted turnbuckles may need to be

readjusted to grade. Readjust the cenĆ

termost turnbuckles and continue adĆ

justing outward. When all adjustments

are completed, hold the turnbuckle

from further movement and tighten the

jam nuts.

FIGURE 11

FIGURE 12

CAUTION!

If there is a significant difference beĆ

tween the ambient temperature at set up

and the temperature of the concrete to

be screeded, the edgings may warp due

to thermal expansion. Recheck the

grade of the screed if this is the case.