General – MBW Blitzscreed User Manual

Page 13

11

SECTION ASSEMBLY

GENERAL

The following describes the assembly procedure of screed sections for both Mechanical

and Air Screeds. Most figures shown are of a Mechanical Screed. Section assembly of an

Air Screed is identical except where otherwise stated. It is essential to follow the proper

set-up sequence when assembling the screed for optimum performance.

IMPORTANT!

For steps 1-10, the screed sections

must be on a flat surface.

1. Determine the number of sections reĆ

quired to obtained the proper screed

length. Arrange the sections so the lonĆ

ger sections are in the middle and the

shorter sections are at the ends.

2. For the mechanical screed affix an enĆ

gine kit to one of the end sections or to

the middle section. Refer to Engine

Assembly for engine kit installation.

3. If an air screed is being used, refer to

Air Drive Assembly for instruction on

assembling air drive and end frames.

4. Assemble end frames and winches to

the end sections. Refer to End Frame

Assembly for installation of end

frames.

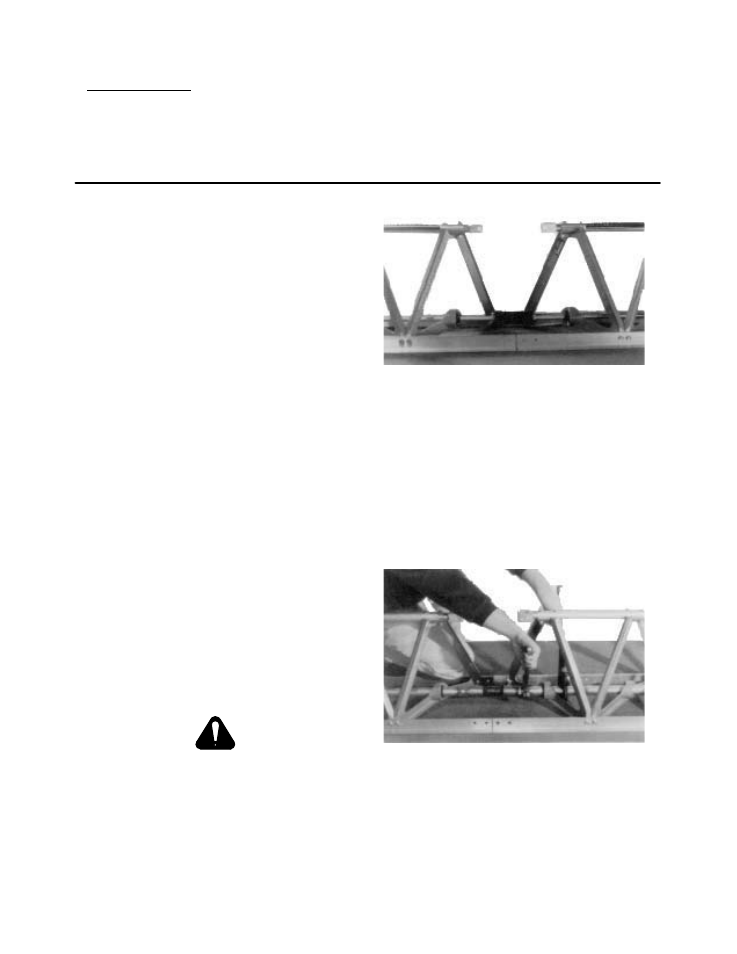

5. Start assembling sections at one end of

the screed. For mechanical screeds

place a flex coupling along with two flex

coupling collars between the two couĆ

pling drivers of adjoining sections. ColĆ

lars should be slid out to the ends of the

flex coupling (see Figure 2).

Check that the two vibrating shaft

offsets are in line.

IMPORTANT !

Assemble all sections in this manner.

Sight down top tubes of all sections

joined and straighten sections if necesĆ

sary.

FIGURE 2

For the air screed join the threaded

manifold ends with a manifold hose.

Use a pipe wrench to prevent the manĆ

ifold from turning while the hose ends

are tightened onto the manifold ends

(see Figure 3). Assemble all sections in

this manner. Sight down top tubes of all

sections joined and straighten sections

if necessary.

FIGURE 3

6. Install a two bolt splice plate thru float

edging. Install a four hole splice plate

on the outside of edging and loosely

install four blind nuts (see Figures 4 and

5).