To check tension, Figure 7-3: belt tension gauge, Figure 7-4: tension gauge – Hale CAFSPro User Manual

Page 57

Routine Maintenance

❑

57

CAFSPro User Operation Manual

p/n: 029-0020-75-0

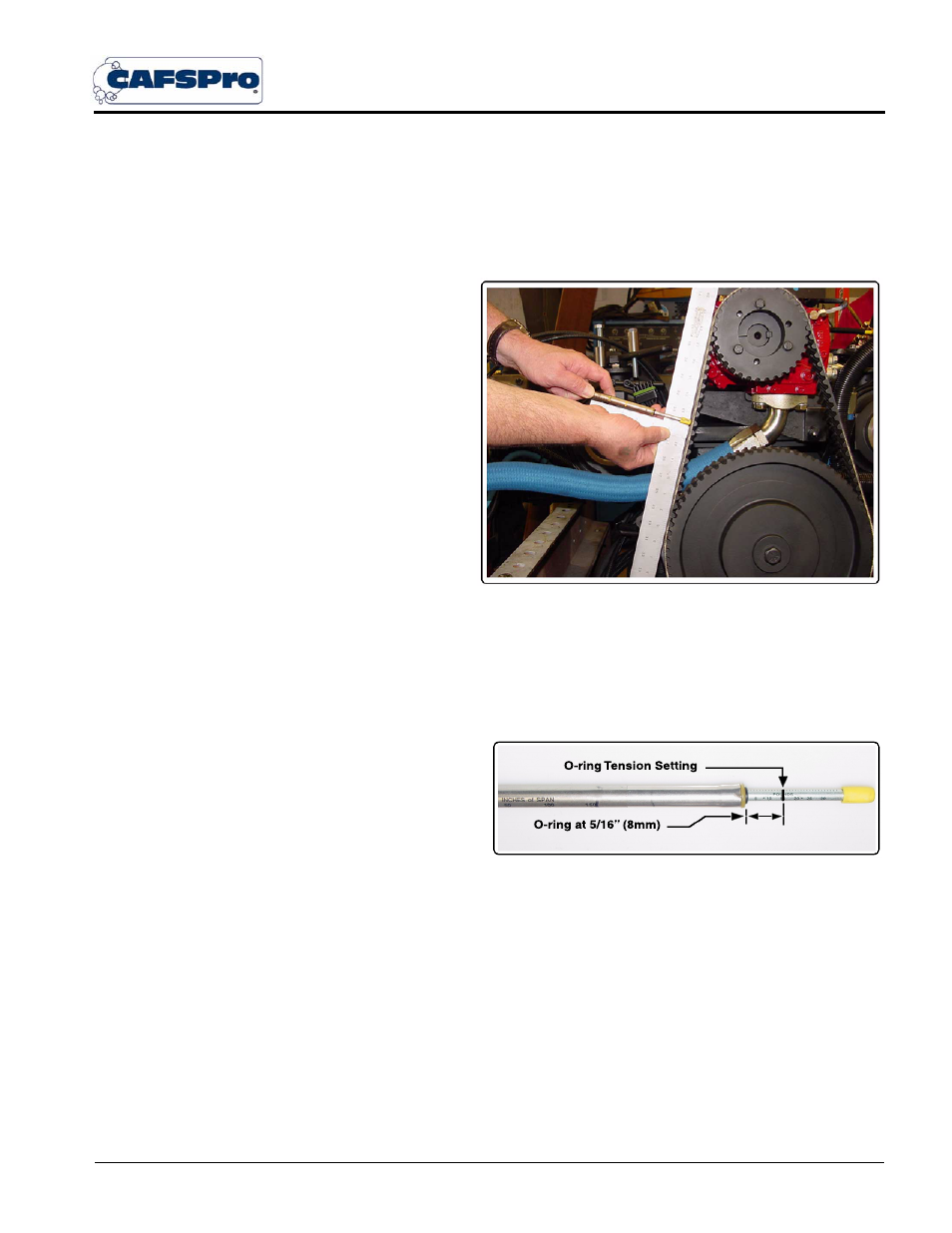

To Check Tension

Use a belt tension gauge to determine the tension applied to the belt and

check on the left side of the unit. (See Figure 7-3: ‘Belt Tension Gauge.’)

When applying a

load of 16 to 20 lbs.

(7 to 9 kg.), perpen-

dicular to the belt,

the deflection

should be no more

than 5/16”(8mm).

If the deflection is

more or less than 5/

16” (8mm), follow

the procedure

below to tighten,

respectively –

loosen the belt to

exert the neces-

sary tension on the

gauge. (See Figure

7-4: ‘Tension Gauge.’)

Note: The tension gauge shown is a Goodyear

®

Industries, Tension Tester.

(Order from Hale Products, p/n: 029-0680-00-0.)

When the gauge is

set perpendicular to

the belt, use a refer-

ence point on the

body of the gauge

that coincides with a

mark on a scale (or a

ruler), held in a fixed

position next to the

gauge.

Push gauge towards the belt until the body of the gauge moves 5/16” (8

mm) along the scale (or ruler). Remove the gauge and read the tension

that the rubber O-ring marked. If tension is lower than 16 lbs. (7 kg.), the

belt is loose; if the tension is greater than 20 lbs. (9kg.), the belt is too tight.

(See Figure 7-4: ‘Tension Gauge.’)

Figure 7-3: Belt Tension Gauge

Figure 7-4: Tension Gauge