Figure 4-5: cafspro typical operating ranges – Hale CAFSPro User Manual

Page 41

Operation

❑

41

CAFSPro User Operation Manual

p/n: 029-0020-75-0

When a suitable booster tank with direct fill is available, running the pressur-

ized water source into the tank, and running the CAFSPro system while tak-

ing suction from the tank, eliminates the problem of higher water pressure

than desired.

Gating the pump discharges reduces hand line pressure when water is flow-

ing. However, when the nozzle is closed momentarily, line pressures rise to

meet master pump pressure. This makes nozzle reaction excessive when

the nozzle is again opened.

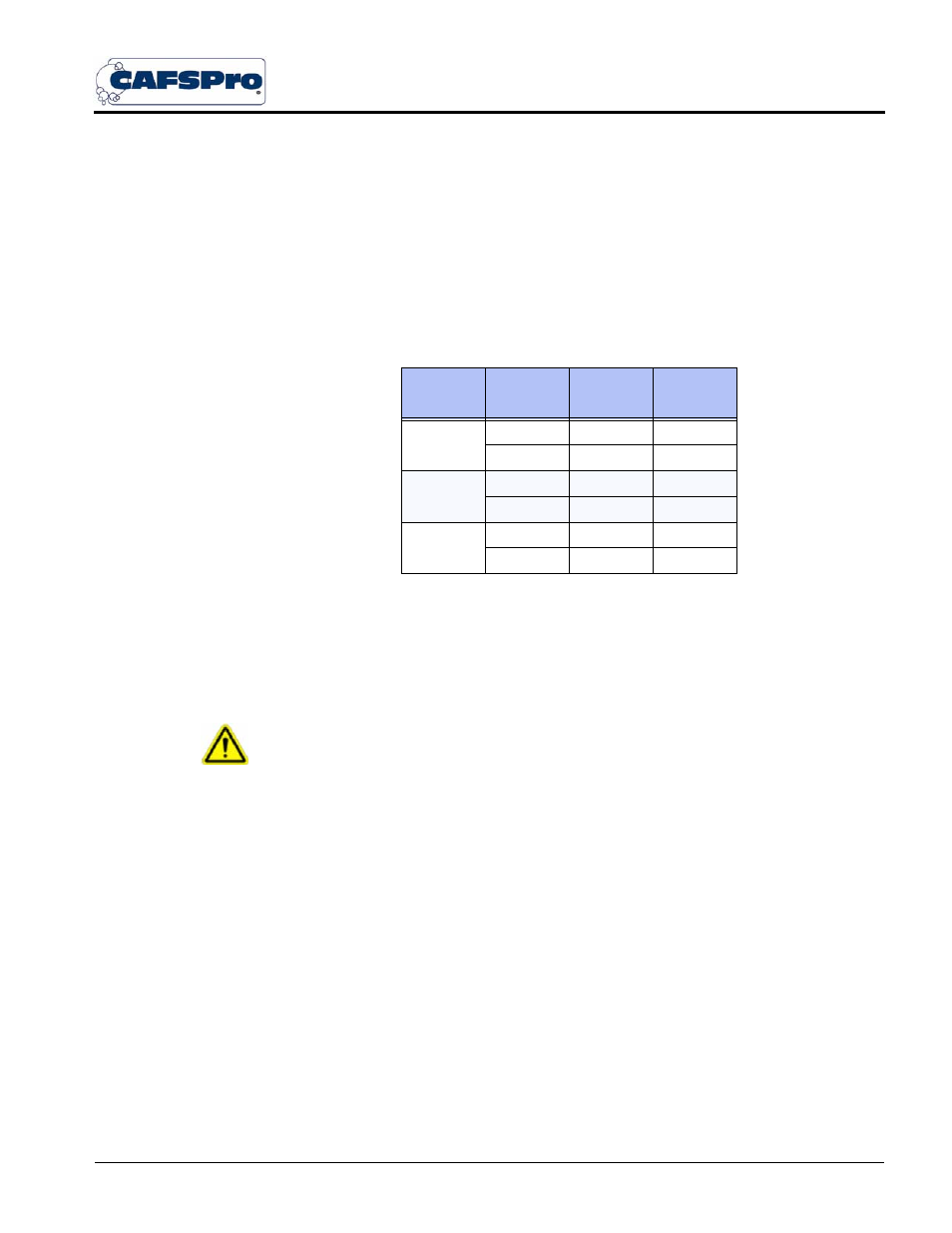

Figure 4-5: CAFSPro Typical Operating Ranges

Note: CAFS hose lines store energy in compressed air when the nozzle is closed

and, nozzle reaction, when opened, can be severe.

WARNING !

DO NOT USE AN AUTOMATIC PRESSURE GOVERNOR IN PRESSURE CON-

TROL MODE WITH CAFS. THE PRESSURE GOVERNOR RESPONDS TO

CHANGES IN PRESSURE AND COULD, WITHOUT WARNING, REDUCE

ENGINE SPEED. THIS REDUCTION IN SPEED COULD REDUCE THE AVAIL-

ABLE AIR CAPACITY OF THE CAFS SYSTEM.

INADEQUATE AIR SUPPLY CREATES AN INEFFECTIVE FIRE FIGHTING

STREAM THAT COULD PLACE FIRE CREWS AT GREATER RISK.

ALWAYS OPEN NOZZLES SLOWLY WHEN FLOWING A CAFS HOSE LINE TO

PREVENT EXCESSIVE NOZZLE REACTION FORCE. ALSO SEE SECTION 1

“SAFETY PRECAUTIONS” ON PAGE 7.

Note: The compressor clutch engages when the pump shifts from ROAD to

PUMP.

Pump

Model

Ratio

Engine

RPM

Pressure

PSI (Bar)

QMAX

23

1050

100 (7)

21

1170

100 (7)

QPAK

23

1155

100 (7)

21

1285

100 (7)

QFLO

23

1709

100 (7)

21

1235

100 (7)