Hale Q Series Muscle User Manual

Page 95

95

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

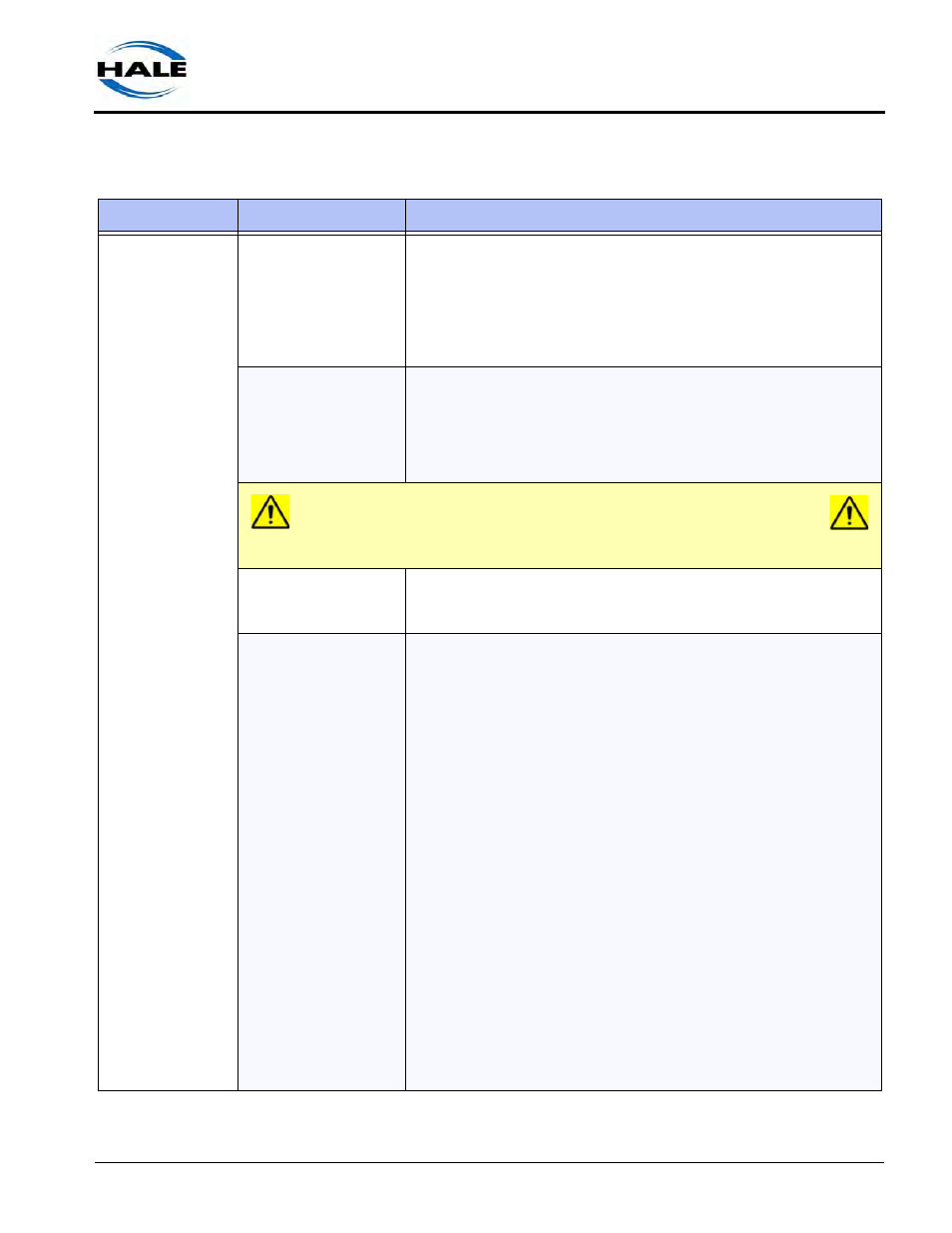

Troubleshooting

Pump Loses

Prime or Will Not

Prime -

continued.

Note: Weekly

priming is rec-

ommended to

ensure proper

operation. See

Section 4 Pre-

ventive Mainte-

nance, heading

“Priming Sys-

tem Test” on

page 74.

Air trapped in suction

line.

• Avoid placing any part of the suction hose higher than the suction

intake.

• Suction hose should be laid out with continuos decline to fluid

supply.

• If trap in hose is unavoidable, repeated priming may be needed to

eliminate air pockets in suction hose.

Insufficient priming

• Proper priming procedures should be followed.

• Do not release the primer control before assuring a complete

prime.

• Open the discharge valve slowly during completion of prime to

ensure complete prime.

NOTICE!

DO NOT RUN THE PRIMER OVER FORTY-FIVE (45) SECONDS. IF PRIME IS

NOT ACHIEVED WITHIN 45 SECONDS, STOP AND LOOK FOR CAUSES (AIR

LEAKS OR BLOCKED SUCTION HOSES.)

Pump pressure too

low when nozzle is

opened.

• Prime pump again and maintain higher pump pressure while

opening the discharge valve slowly.

Air leaks

• Attempt to located and correct air leaks using the following proce-

dures:

• Perform “Dry Vacuum Test” on pump per NFPA standards with 22”

minimum vacuum required with loss not to exceed 10” Hg. in five

(5) minutes.

• If a minimum of 22” Hg. cannot be achieved, the priming device or

system may be inoperative, or the leak is too big for the primer to

overcome (such as an open valve). The loss of vacuum indicates

leakage and could prevent priming or cause loss of prime.

• After priming shut OFF the engine. Audible detection of a leak is

often possible.

• Connect the suction hose from the hydrant or the discharge of

another pumper to pressurize the pump with water. Look for visi-

ble leakage and correct. A pressure of 100 PSI (689 kPa) should

be sufficient. DO NOT exceed pressure limitations of pump,

accessories or piping connections.

• Check pump packing during attempt to locate leakage. If leakage

is in excess of recommendations, adjust accordingly. See Section

4 Preventive Maintenance, heading “Repacking the Seal” on page

85.

• The suction side relief valve can leak. Plug the valve outlet con-

nection and retest

Table 6-1: Muscle (Midship) Pump Troubleshooting (Sheet 3 of 9)

Condition

Possible Cause

Suggested Corrective Action