Hale Q Series Muscle User Manual

Page 94

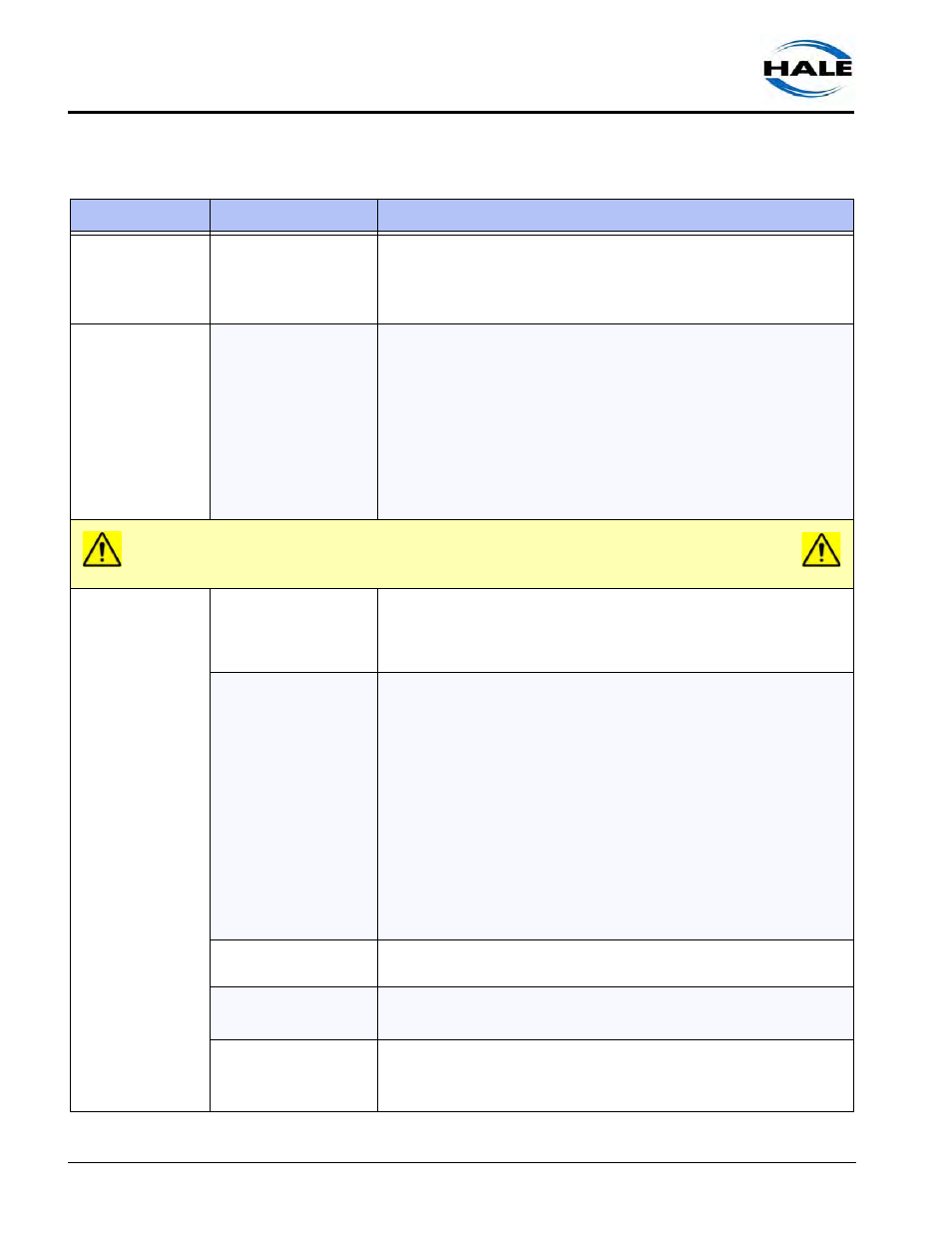

Troubleshooting

94

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Pump Will Not

Engage-contin-

ued.

• Repeat recommended shift procedures with transmission in the

NEUTRAL position.

• Release brake system momentarily, then reset and repeat recom-

mended shifting procedures.

Automatic trans-

mission with

Power Pump Shift

Insufficient air in shift

system.

Air leaks in shift sys-

tem.

• Repeat recommended shift procedures with transmission in the

NEUTRAL position.

• Check system for loss of air and possible air leaks. Use manual

override procedures, if necessary.

• Also see heading “Standard transmission with Power Pump Shift.”

on page 93.

• Attempt to locate and repair leak(s). Leakage, if external, may be

detected audibly. Internal leakage is more difficult to detect and

requires disassembly.

WARNING!

DO NOT LEAVE THE CAB OR ATTEMPT TO PUMP UNTIL ALL THE

GREEN PUMP LIGHTS IN THE CAB AND PANEL ARE ILLUMINATED

Pump Loses

Prime or Will Not

Prime.

Note: Weekly

priming is rec-

ommended to

ensure proper

operation. See

Section 4 Pre-

ventive Mainte-

nance, heading

“Priming Sys-

tem Test” on

page 74.

Electric priming sys-

tem.

• NO recommended engine speed is required to operate the elec-

tric primer. However, 1,000 engine RPM maintains the electrical

system while providing enough speed for initial pumping opera-

tions. Also see heading “Priming Valves” on page 41.

Inoperative priming

system or possible

clogged priming

pump.

Note: Using lubricant on the vanes and vane slots during disas-

sembly and cleaning eventually causes a gummy residue to

develop, rendering the system inoperative. DO NOT lubricate

vanes or vane slots.

• Check the priming system by performing a “Dry Vacuum Test” per

NFPA standards. If the pump holds vacuum but primer pulls less

than 22” Hg, it could indicate excessive wear in the primmer.

• See Section 4 Preventive Maintenance, heading “Weekly” on

page 72. Also see Section 4 Preventive Maintenance, heading

“Annual” on page 79.

• Also see heading “Priming Valves” on page 41.

• Repair and/or replace accordingly.

Suction lifts too high.

• DO NOT attempt lifts exceeding 22 feet (6.7 meters) except at low

elevation.

Blocked suction

strainer.

• Remove obstruction from suction hose strainer.

• Thoroughly clean strainer screen.

Suction connections.

• Clean and tighten all suction connections.

• Check suction hose and hose gaskets for possible defects - repair

and/or replace accordingly.

Table 6-1: Muscle (Midship) Pump Troubleshooting (Sheet 2 of 9)

Condition

Possible Cause

Suggested Corrective Action