Hale Q Series Muscle User Manual

Page 100

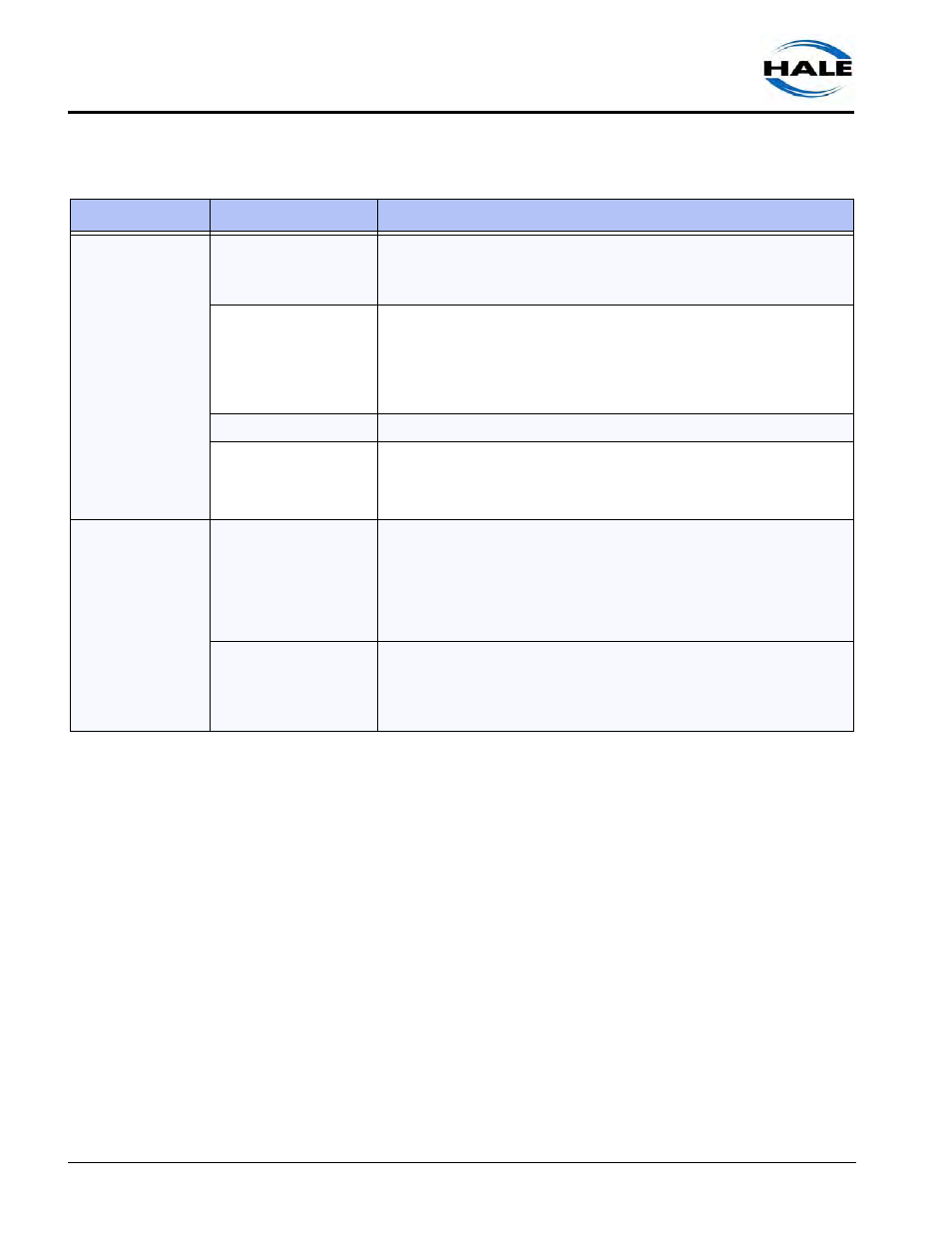

Troubleshooting

100

MUSCLE (Midship) Pumps Installation, Operation, and Maintenance Manual

p/n: 029-0020-63-0

Unable to Obtain

Proper Setting on

Relief Valves.

Using the wrong pro-

cedures.

• Check instructions for setting the relief valve and reset.

• See Section 3 Operation, heading “Relief Valve Procedures” on

page 66.

Blocked strainer.

• Check and clean the strainer in the supply line from the pump dis-

charge to the control valve. Check truck manual for the exact loca-

tion.

• Check and clean tubing lines related to the relief and control

valves.

Dirty control valve.

• Remove the control valve and clean.

“Hunting” condition.

• Insufficient water supply from the pump to the control valve.

• Check the strainer and relief valve system for flow restrictions.

• Remove and clean the control valve.

Discharge Valves

Are Difficult to

Operate.

Lack of lubrication.

• Recommended weekly lubrication of discharge and suction valve.

• Use a good grade petroleum based silicone grease.

• Foe Hale Products, SVS Valves, etc., use Never-Seez® White

Food Grade with PTFE.

• Refer to separate valve manual for addition information.

Valve in need of more

clearance for opera-

tion.

• Multi-gasket design allows additional gaskets fro more clearance

and free operation.

Note: Adding too many gaskets to the valve eventually causes

leakage.

Table 6-1: Muscle (Midship) Pump Troubleshooting (Sheet 8 of 9)

Condition

Possible Cause

Suggested Corrective Action