Caution – Bryant 313AAV User Manual

Page 5

5

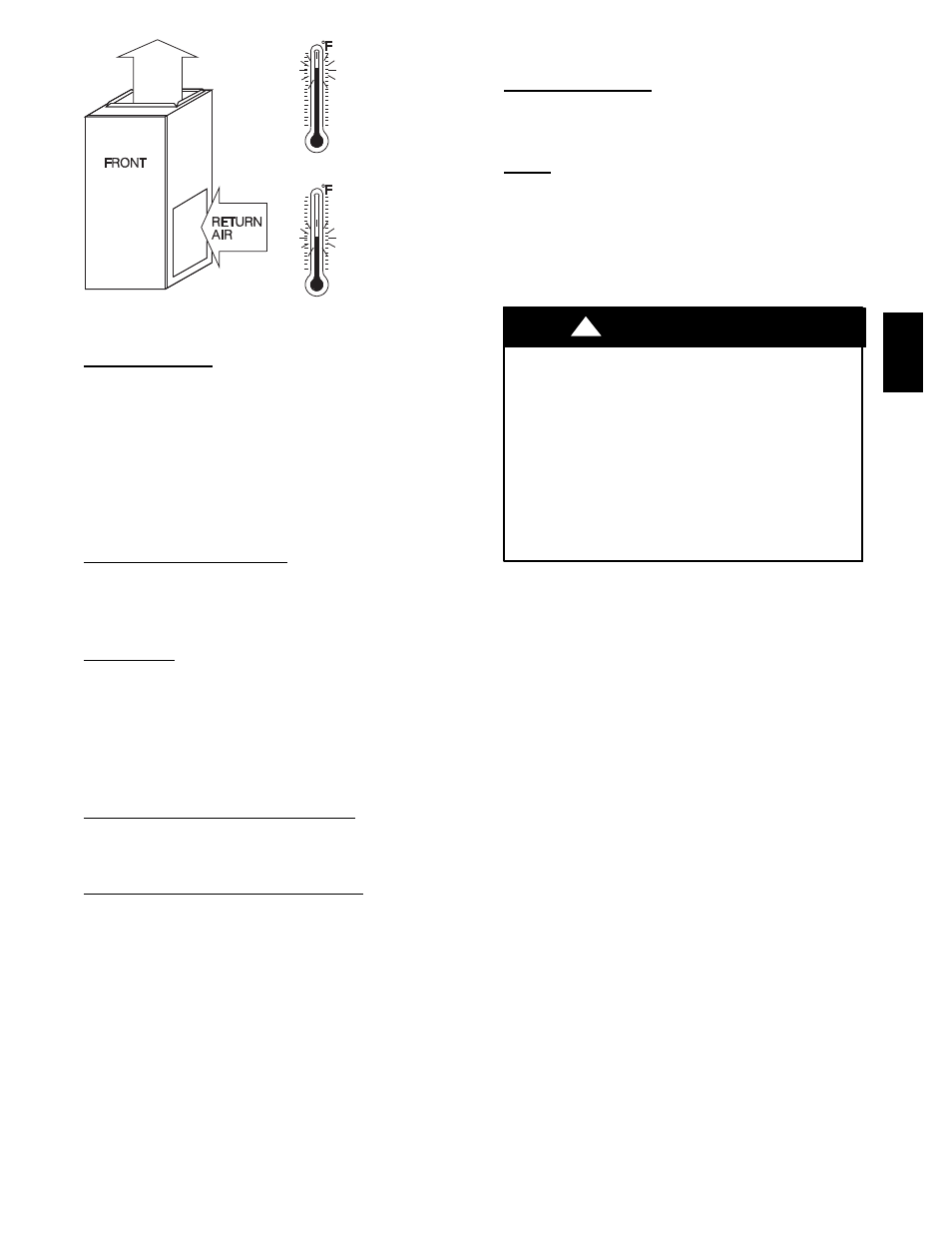

Min 60ºF / 16ºC

Max 85ºF/ 29ºC

A02055

Fig. 3 -- Return Air Temperature

General Installation

S

US: Current edition of the NFGC and the NFPA 90B.

For copies, contact the National Fire Protection

Association Inc., Batterymarch Park, Quincy, MA

02269; (www.NFPA.org) or for only the NFGC,

contact the American Gas Association, 400 N. Capitol

Street, N.W., Washington, DC 20001 (www.AGA.org).

S

CANADA: CAN/CSA--B149.1--05. For a copy,

contact Standard Sales, CSA International, 178

Rexdale Boulevard, Etobicoke (Toronto), Ontario,

M9W 1R3 Canada.

Combustion and Ventilation Air

S

US: NGFC NFPA54/ANSI Z223.1--2006 Section 9.3,

Air for Combustion and Ventilation.

S

CANADA: Part 8 of CAN/CSA--B149.1--05, Venting

Systems and Air Supply for Appliances.

Duct Systems

S

US and CANADA: Air Conditioning Contractors

Association (ACCA) Manual D, Sheet Metal and Air

Conditioning Contractors National Association

(SMACNA), or American Society of Heating,

Refrigeration, and Air Conditioning Engineers

(ASHRAE) 2005 Fundamentals Handbook Chapter 35

or 2004 HVAC Systems and Equipment Handbook

Chapters 9 and 16.

Acoustical Lining and Fibrous Glass Duct

S

US and CANADA: current edition of SMACNA and

NFPA 90B as tested by UL Standard 181 for Class I

Rigid Air Ducts

Gas Piping and Gas Pipe Pressure Testing

S

US: NFGC NFPA54/ANSI Z223.1--2006; chapters 5,

6, 7, and 8 and National Plumbing Codes.

S

CANADA: CAN/CSA--B149.1--05 Parts 4, 5, and 6

Appendices A, B, E, and H.

Electrical Connections

S

US: National Electrical Code (NEC) ANSI/NFPA

70--2008.

S

CANADA: Canadian Electrical Code CSA C22.1.

Venting

S

US: NFGC NFPA 54 / ANSI Z223.1--2006; Chapters

12 and 13.

S

CANADA: CAN/CSA--B149.1--05 Part 8 and

Appendix C.

ELECTROSTATIC DISCHARGE (ESD)

PRECAUTIONS PROCEDURE

FURNACE RELIABILITY HAZARD

Improper installation or service of furnace may cause

premature furnace component failure.

Electrostatic discharge can affect electronic components.

Follow the Electrostatic Discharge Precautions Procedure

listed below during furnace installation and servicing to

protect the furnace electronic control. Precautions will

prevent electrostatic discharges from personnel and hand

tools which are held during the procedure. These

precautions will help to avoid exposing the control to

electrostatic discharge by putting the furnace, the control,

and the person at the same electrostatic potential.

CAUTION

!

1. Disconnect all power to the furnace. Multiple disconnects

maybe required. DO NOT TOUCH THE CONTROL OR

ANY WIRE CONNECTED TO THE CONTROL PRIOR

TO

DISCHARGING

YOUR

BODY’S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch the clean, unpainted, metal surface of the

furnace chassis which is close to the control. Firmly touch

the clean, unpainted, metal surface of the furnace chassis

which is close to the control. Tools held in a person’s hand

during grounding will be satisfactorily discharged.

3. After touching the chassis, you may proceed to service the

control or connecting wires as long as you do nothing to

recharge your body with static electricity (for example;

DO NOT move or shuffle your feet, do not touch

ungrounded objects, etc.).

4. If you touch ungrounded objects (and recharge your body

with static electricity), firmly touch a clean, unpainted

metal surface of the furnace again before touching control

or wires.

5. Use this procedure for installed and uninstalled

(ungrounded) furnaces.

313A