Installation, Upflow installation, 313a – Bryant 313AAV User Manual

Page 10

10

of at least 2 in.

2

/1,000 Btuh (4,400 mm

2

/kW) of total

input rating of all gas appliances.

2. An attic or crawlspace may be considered a space that

freely communicates with the outdoors provided there are

adequate permanent ventilation openings directly to

outdoors having free area of at least 1--in.

2

/4,000 Btuh of

total input rating forall gas appliances in the space.

3. In spaces that use the Indoor Combustion Air Method,

infiltration should be adequate to provide air for

combustion, permanent ventilation and dilution of flue

gases. However, in buildings with unusually tight

construction, additional air MUST be provided using the

methods described in the Outdoor Combustion Air

Method section.

Unusually tight construction is defined as construction with:

a. Walls and ceilings exposed to the outdoors have a

continuous, sealed vapor barrier. Openings are gasketed

or sealed and

CIRCULATING AIR

DUCTS

6" MIN

(FRONT)

Ü

CIRCULATING AIR DUCTS

VENT THROUGH ROOF

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR

WALL

12" MAX

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR

WALL

12" MA X

UNCONFINED

SPACE

INTERIOR

HEATED

SPACE

CLEARANCE IN FRONT OF COMBUSTION AIR

OPENINGS SHALL

BE A

T LEAST 3 IN.

(305mm)

(152mm)

(305mm)

*Minimum opening size is 100 in.

2

with minimum dimensions of 3 in. (76

mm).

*Minimum of 3 in. (76 mm), when type ---B1 vent is used.

A03175

Fig. 8 -- Air for Combustion, Ventilation, and Dilution from

Indoors

b. Doors and openable windows are weatherstripped and

c. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall--ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Combination of Indoor and Outdoor Air

1. Indoor openings shall comply with the Indoor

Combustion Air Method below and,

2. Outdoor openings shall be located as required in the

Outdoor Combustion Air Method menioned previously

and,

3. Outdoor openings shall be sized as follows:

a. Calculate the Ratio of all Indoor Space volume divided

by required volume for Indoor Combustion Air

Method below.

A02098

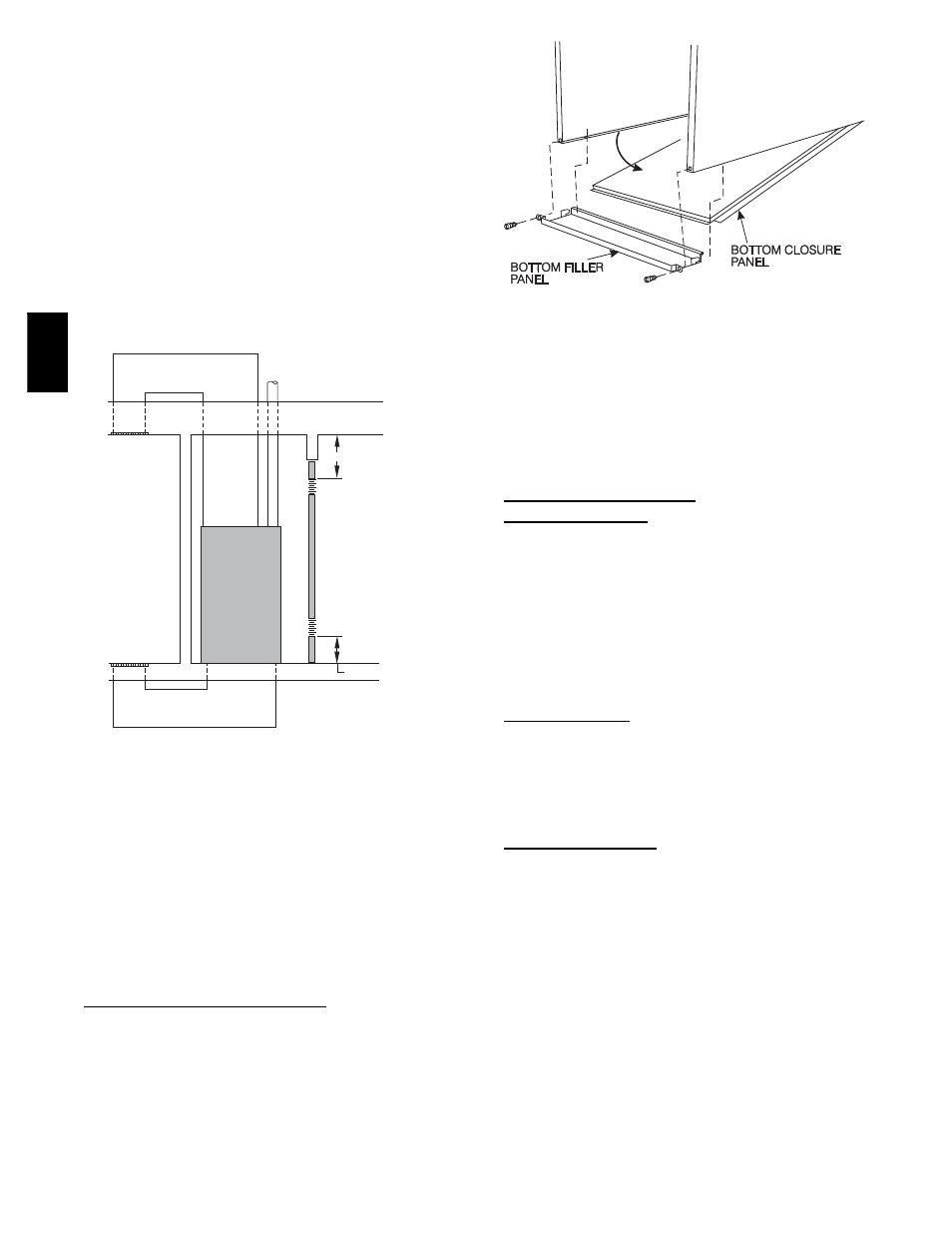

Fig. 9 -- Removing Bottom Closure Panel

b. Outdoor opening size reduction Factor is 1 minus the

Ratio in a. above.

c. Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor in b. above. The minimum

dimension of air openings shall be not less than 3 in. (80

mm).

INSTALLATION

UPFLOW INSTALLATION

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove two screws holding

bottom filler panel. (See Fig. 9.)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. This panel MUST be in place when

only side return air is used.

NOTE: Side return--air openings can be used in UPFLOW and

most HORIZONTAL configurations. Do not use side return--air

openings in DOWNFLOW configuration.

Leveling Legs (If Desired)

In upflow position with side return inlet(s), leveling legs may be

used. (See Fig. 10.) Install field--supplied, 5/16 x 1--1/2 in. (8 x

38 mm) (max) corrosion--resistant machine bolts, washers and

nuts.

NOTE: Bottom closure must be used when leveling legs are

used. It may be necessary to remove and reinstall bottom closure

panel to install leveling legs. To remove bottom closure panel, see

Item 1. in Bottom Return Air Inlet section.

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in

each bottom corner of furnace. (See Fig. 10.)

2. For each leg, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install

flat washer if desired.)

313A