Function fittings and flow controls, Guidelines for typical installation – Norgren Flow Controls User Manual

Page 20

FIT-3-20

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

Function Fittings and Flow Controls

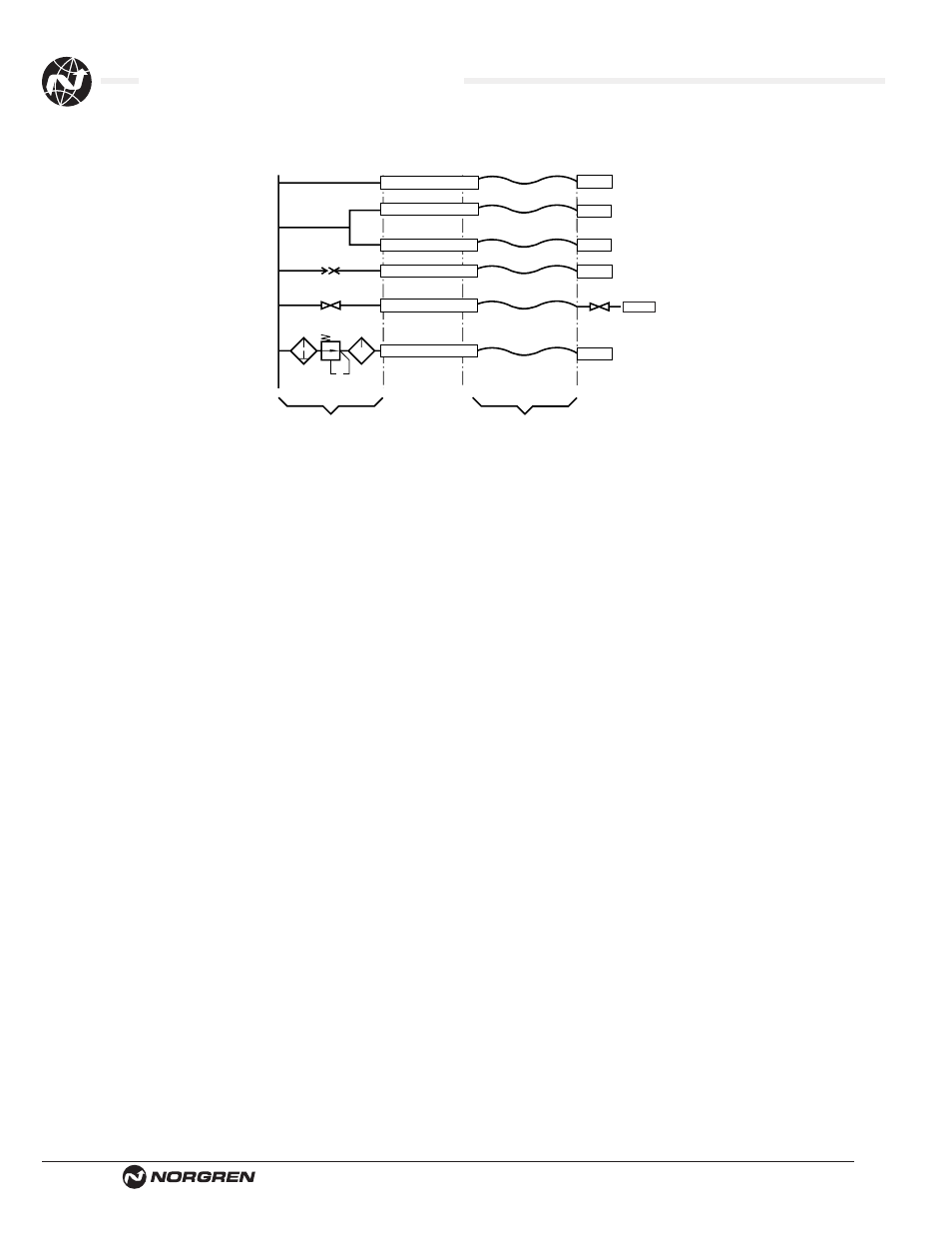

Guidelines for Typical Installation

The air fuse should be installed directly between fixed or rigid pipework and the flexible tube to protect the whole

length of the flexible tube. Only tubing after the air fuse is protected. The air fuse must be installed in the correct

orientation. Failure to do this will render it ineffective. When a shut off valve is located before the air fuse, the

valve must be opened slowly in order to control initial air flow and avoid decompression effects which may trip the

air fuse.

It should be noted that the OSHA standard (29 CFR ChXVII Para 1926.302-b7) relating to pneumatic power tools

states “All hoses exceeding 1/2" inside diameter shall have a safety device at the source of supply or branch

line to reduce pressure in the case of hose failure.”

Choosing an Air Fuse*

a) The port size of the air fuse should be nominally equal to that of the supply lines - e.g. a 1⁄2 (12.7 mm) air fuse

should be used with a 1⁄2'' (12.7mm) ID hose.

b) Always select the high flow model (91) if there is sufficient system pressure for the length of hose to be

protected. See tables hose length vs. minimum supply pressure.

c) If there is insufficient system pressure, or long hose lengths are to be protected, use model 90.

d) After installation always test each valve for proper function. See section below on how to check an air fuse.

e) The pneumatic system must be capable of delivering the flow required to activate the air fuse. For this reason,

the air fuse is not suitable for use with the Norgren R07 miniature range in certain installations.

f) For use with spring coils consult table. See table flow vs. pressure supply.

Verifying Operation of an air fuse

●

Install the air fuse following the instructions supplied

●

Connect tool or complete circuit to the air line

●

Switch on operation to ensure a complete cycle is performed

●

If tool or complete circuit starts and runs satisfactorily, stop operation and drain air line. Disconnect hose from

tool or circuit and secure hose end. Turn on air supply progressively (to avoid decompression effect). Prior to

fully reaching operation conditions, the air fuse should suddenly activate and cut off the flow. A slight air flow

will remain as part of the automatic re-set function. If the air fuse is not activated the unit should be

disconnected and the lower flow range air fuse should be used.

* Consult factory for the availability of Excel™ based sizing program.

AIR SUPPLY

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

RIGID LINE

FLEXIBLE LINE

Air Fuse

Air Fuse

Air Fuse

Air Fuse

Air Fuse

Air Fuse