Troubleshooting – SawStop ICS73600 User Manual

Page 76

74

SawStop 10” Industrial Cabinet Saw

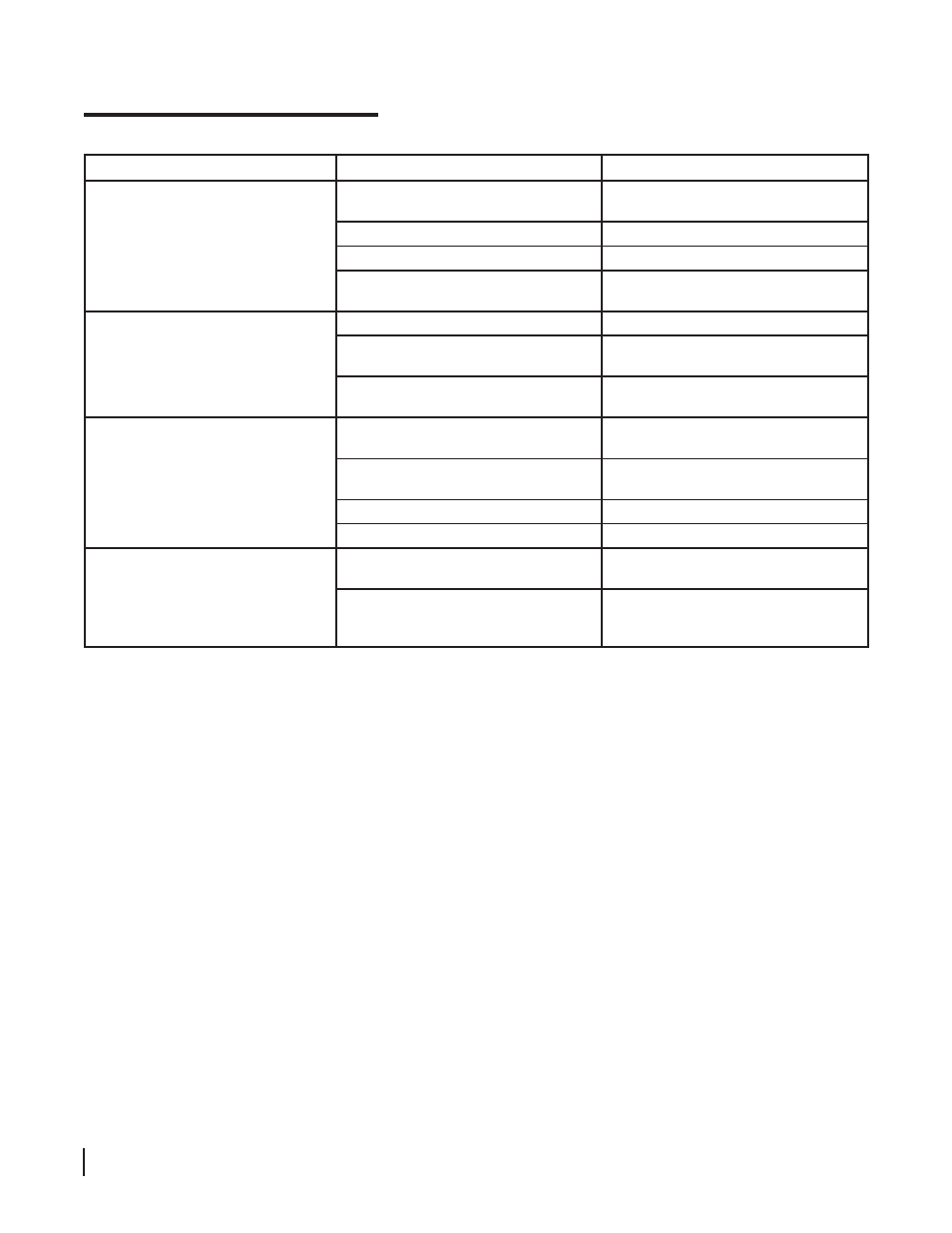

Problem

Possible Cause(s)

Solution

The material binds when making a rip

cut.

1. The rip fence is not aligned with the

blade.

1. Align the fence to the blade.

2. The material is warped.

2. Select another piece of material.

3. The feed rate is too high.

3. Try again at a lower feed rate.

4. The spreader or riving knife is not

aligned with the blade.

4. Align the spreader or riving knife.

The cuts are not even and/or clean.

1. The blade is dull.

1. Replace or sharpen the blade.

2. The blade is coated with pitch, gum

or other material.

2. Clean or replace the blade.

3. The blade is not the correct blade for

the material or cut.

3. Replace the blade.

The saw vibrates too much.

1. The blade is damaged or

unbalanced.

1. Replace the blade.

2. The floor is uneven.

2. Move the saw to a level, even

surface.

3. The bearings are worn.

3. Replace the bearings.

4. The belts are worn.

4. Replace the belts.

The motor starts slowly and/or fails to

reach nominal speed.

1. The electrical supply voltage is too

low.

1. Ensure that the correct voltage is

being supplied to the saw.

2. The electrical supply line to the saw

is under-rated.

2. Ensure that the line that supplies

power to the saw is correctly sized

for the required voltage and current.

Troubleshooting