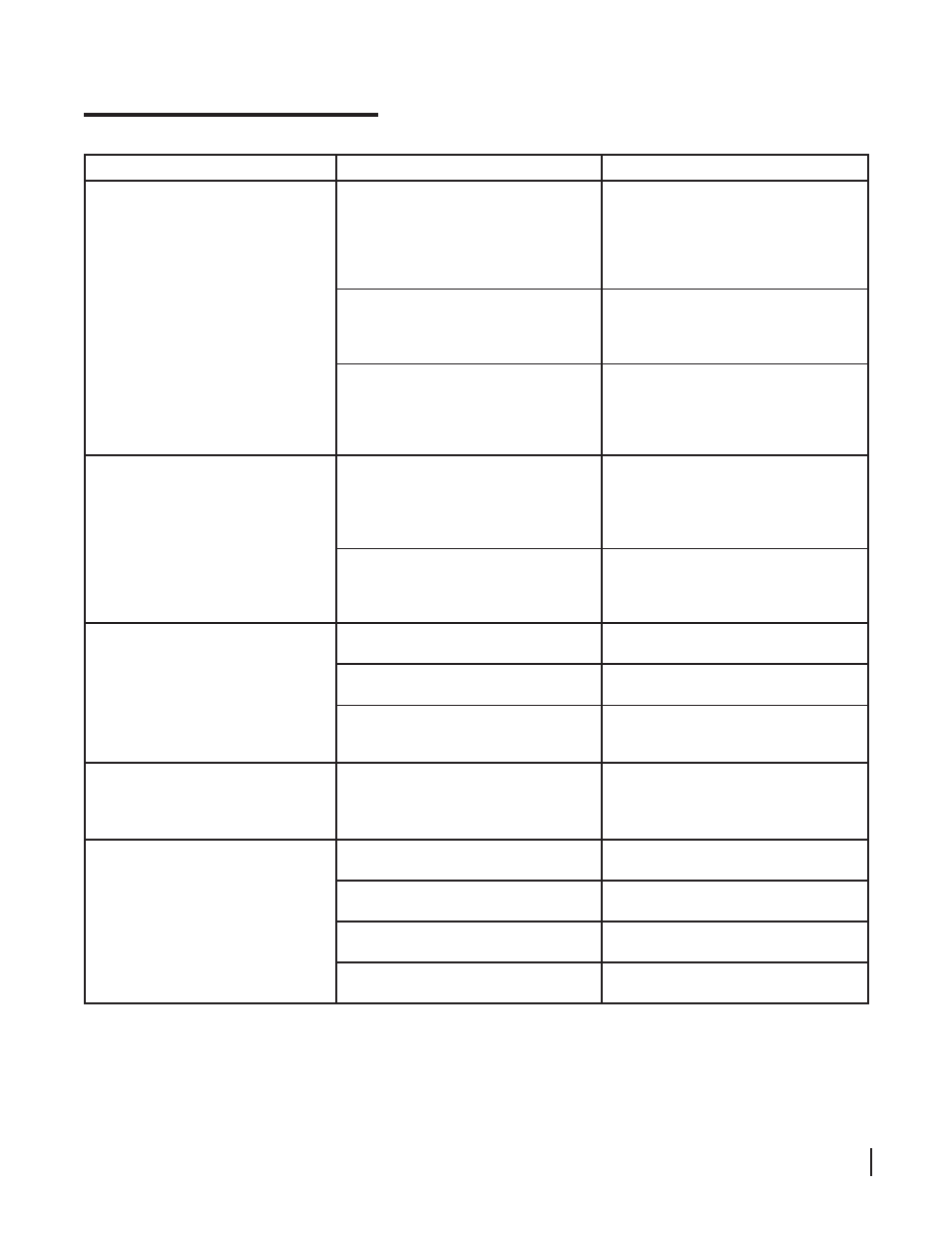

Troubleshooting, Problem possible cause(s) solution – SawStop ICS73600 User Manual

Page 75

SawStop 10” Industrial Cabinet Saw 73

Problem

Possible Cause(s)

Solution

The blade slows down during cut, but

does not stop.

1. One of the belts is not properly

tensioned.

1. Check the tension of the motor belt

and arbor belt. If the motor belt is

too loose, adjust the position of the

motor to provide the correct tension

on the motor belt. If the arbor belt is

too loose, replace it with a new belt.

2. The blade is binding on the wood.

2. Ensure the spreader or riving knife

is aligned with the blade. If using the

rip fence, ensure it is aligned parallel

to the blade.

3. The voltage supplied to the motor is

incorrect.

3. Ensure the power to the terminal box

is the correct voltage and phase.

Also ensure the wiring to the saw

is the correct gauge for the peak

current draw specified for the motor.

The blade hits the brake pawl during

installation.

1. The brake position is adjusted too

close to the blade.

1. Turn the brake positioning bolt

counter-clockwise until the closest

point between the brake pawl and

the blade is about

1

/

16

inch to

1

/

8

inch.

2. The blade is the wrong size.

2. Use only a 10 inch diameter blade

with a standard brake cartridge,

or an 8 inch dado set with a dado

cartridge.

The gears sound/feel rough when

raising or lowering the blade.

1. There is dust or debris on the miter

gears or elevation shaft.

1. Clean components and regrease.

2. The lock nut below the vertical miter

gear is too loose or too tight.

2. Tighten or loosen the lock nut as

necessary.

3. The elevation locking knob has not

been released.

3. Turn the elevation locking knob

counter-clockwise to release the

elevation hand wheel.

There is play in the tilt control so that

the tilt hand wheel can be turned at

least

1

/

8

revolution without changing

the tilt angle of the blade.

1. The worm gear is not engaged fully

on the front trunnion sector gear.

1. Adjust the position of the tilt control

shaft as necessary to ensure the

worm gear engages fully with the

front trunnion sector gear.

The saw does not make accurate 45°

or 90° cuts.

1. The tilt limit stops are not adjusted

properly.

1. Adjust the tilt limit stops.

2. The tilt angle indicator is not

adjusted properly.

2. Adjust the tilt angle indicator.

3. The miter gauge is not adjusted

properly.

3. Adjust the miter gauge.

4. The miter gauge slots are not

aligned with the blade.

4. Align the miter gauge slots to the

blade.

Troubleshooting