Making adjustments to your saw, Adjusting your saw – SawStop ICS73600 User Manual

Page 49

SawStop 10” Industrial Cabinet Saw 47

Adjusting

Your Saw

Making Adjustments to Your Saw

WARNING! Always make sure that both the Disconnect Switch and the Main Power

Switch are in the OFF position before making any adjustments to your saw.

Your SawStop saw has been factory adjusted to rigid specifications to provide the highest quality performance

and results. Additional adjustment or alignment should not be necessary. Nevertheless, your SawStop cabinet

saw has been designed to allow a wide range of adjustments and alignments to achieve the ultimate in

precision. Before changing the alignment of any portion of the saw, make sure you read and understand the

entire alignment procedure.

1. Aligning the Table:

For accurate cuts with the miter gauge, the miter slots in the table should be parallel to the blade. This is also

important for rip cuts since the rip fence should be aligned to the miter slots. Two procedures for aligning

the table are described below. The preferred procedure is described first and provides an accuracy of about

± 0.002 inch. An alternative procedure is also described which provides an accuracy of about ±0.010 inch.

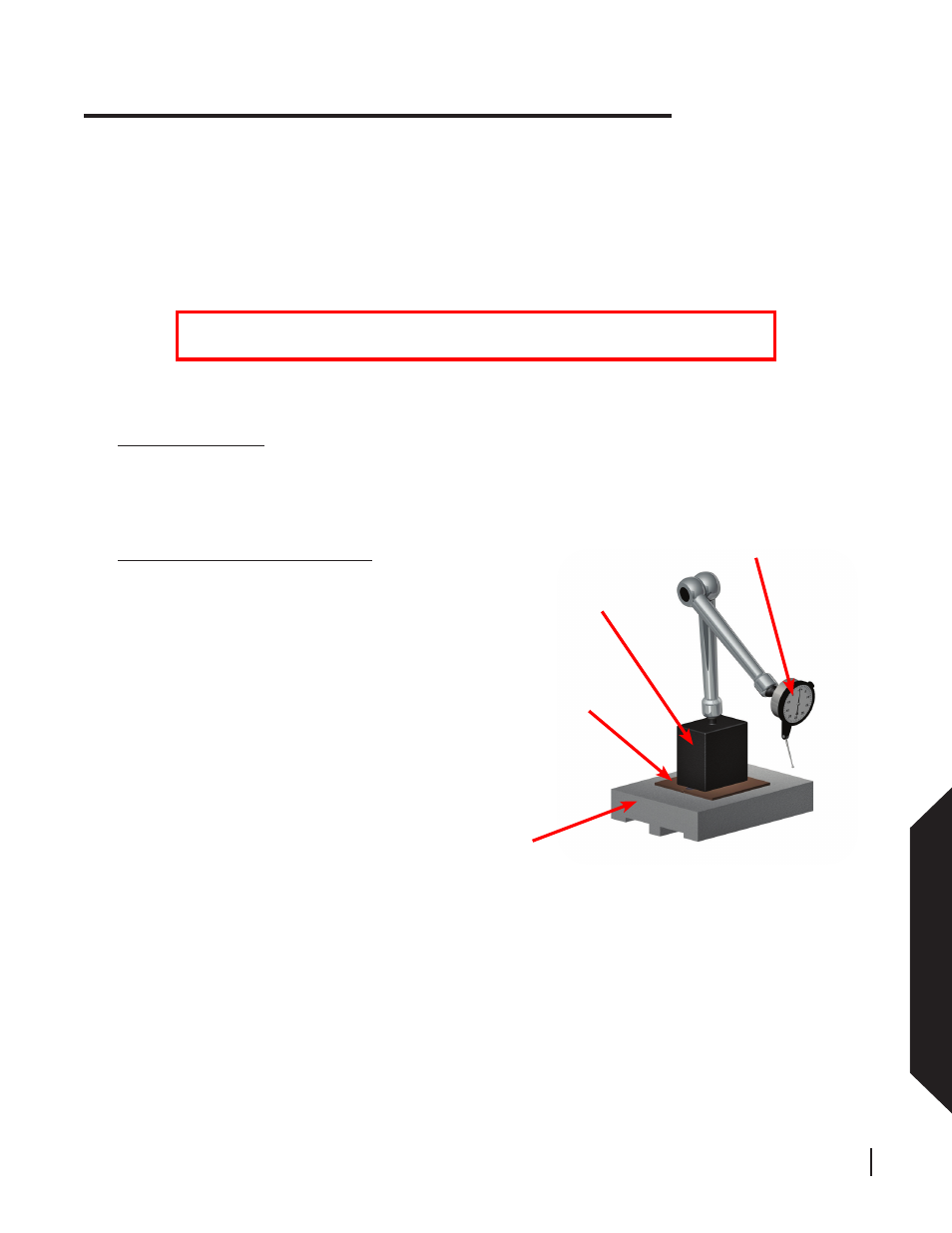

Preferred Table Alignment Procedure

To align the table precisely, you will need a dial test

indicator with a resolution and accuracy of at least

0.0005 inches, and a mount for the indicator that will

slide smoothly in the miter slots. The mount should slide

on the table on either smooth plastic glide plates or on

ball bearing rollers. The mount should also include a

lower rail or similar structure that fits relatively tightly in

the miter slot, but not so tight as to prevent the mount

from sliding. A sample mount is shown in Fig. 53.

Begin by removing the insert as described on page 22, and installing a clean, high-quality blade or precision

blank onto the arbor as described on page 17. The blade should be flat and parallel to within 0.001 inch or less,

and should not be coated with paint or similar materials that may affect the measurement. Attempting to align

the table using a blade that is not very flat will cause similar inaccuracy in the alignment.

Fig. 53

dial test indicator

plastic mount

magnetic base

steel plate