Making adjustments to your saw – SawStop ICS73600 User Manual

Page 70

68

SawStop 10” Industrial Cabinet Saw

Making Adjustments to Your Saw

10. Adjusting the Miter Gauge:

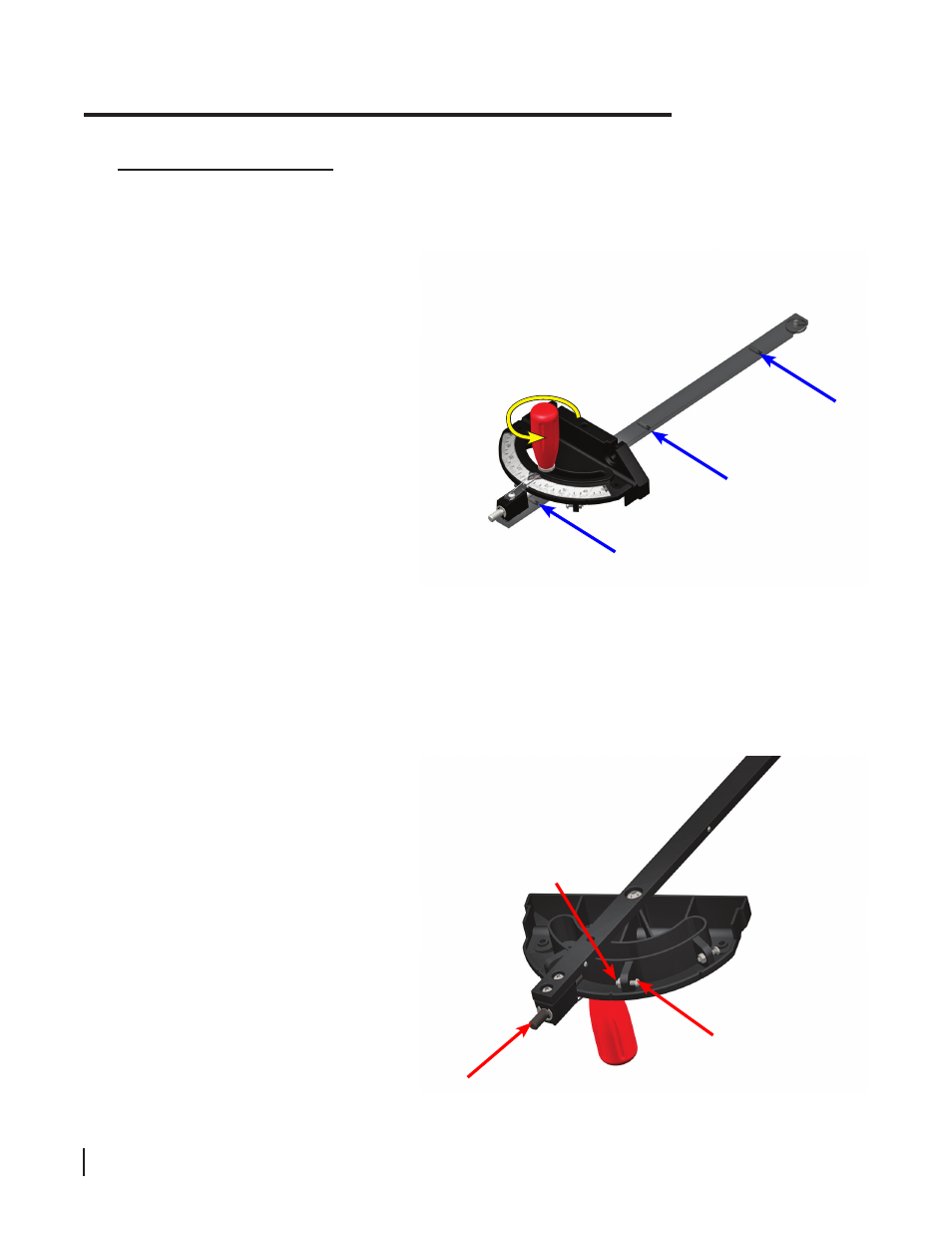

The miter gauge bar includes three spring bearings which ensure a close fit between the miter gauge bar and

the miter gauge slots in the table. The bearings can be adjusted to protrude further outward from the side of

the bar to tighten the fit between the bar and the miter slots. Alternatively, the bearings can be adjusted inward

to loosen the fit. To adjust the position

of the spring bearings, insert a 2.5 mm

hex wrench into the back of the bearing

as shown in Fig. 87. Turn the wrench

clockwise to tighten the fit, or counter-

clockwise to loosen the fit.

The miter gauge also includes indexing

stops to allow you to quickly set the

gauge to -45°, 0°, and +45°. If necessary,

you can adjust these indexing stops

to increase the precision of your miter

cuts.

To begin, loosen the miter gauge head

by turning the locking handle counter-

clockwise about

1

/

2

turn (see Fig. 87).

Next, for the indexing stop you want to adjust, loosen the corresponding locking nut and turn the set screw

counter-clockwise several turns (see Fig. 88). Place the miter gauge in either the left or right miter slot, and set

a combination square to the desired angle (e.g., -45°, 0°, or +45°). Position one leg of the square flush against

the blade and rotate the miter gauge head until it is flush against the other leg of the square.

Next, turn the handle clockwise until it is

tight to lock the miter gauge head at the

correct angle. Make sure the indexing

pin is pressed in toward the miter gauge

bar, then turn the set screw clockwise

until it hits against the indexing pin.

Finally, tighten the locking nut to prevent

the set screw from moving.

Repeat the above process for the other

indexing stops if desired.

Fig. 87

Fig. 88

insert hex wrench to

adjust spring bearings

turn locking

handle to unlock

miter gauge head

locking nut

set screw

indexing pin