Warning, Caution, Unit start up procedure – Comfort-Aire HKV300A User Manual

Page 44

Installation, Operation & Maintenance

HKV SERIES

Heat Controller, LLC

43

1. Turn thermostat fan position to “ON”. Blower should start.

%DODQFHDLUÀRZDWUHJLVWHUV

3. Adjust all valves to their full open position. Turn on the line

power to all heat pump units.

4. Operate unit in cooling cycle. Room temperature should

be approximately 45-100°F [7-38°C] DB. For Start-up

check, loop water temperature entering the heat pumps

should be between 45°F [7°C] and 110°F [43°C].

5. Two factors determine the operating limits of a Heat

Controller HKV System– (a) return air temperature, and

(b) water temperature. When any one of these factors is at

a minimum or maximum level, the other factor must be at

normal levels to ensure proper unit operation.

a. Adjust the unit thermostat to the warmest position.

Slowly reduce thermostat setting until the

compressor activates.

b. Check for cool air delivery at the unit grille within a

few minutes after the unit has begun to operate.

Note8QLWVKDYHD¿YHPLQXWHWLPHGHOD\LQWKHFRQWUROFLUFXLW

that can be eliminated on the CXM PCB as shown below in

Figure 14. See controls description for detailed features of the

control.

c. Verify that the compressor is on and that the water

ÀRZUDWHLVFRUUHFWE\PHDVXULQJSUHVVXUHGURS

through the heat exchanger using the Pete’s

plugs and comparing to Table 7.

d. Check the elevation and cleanliness of the conden-

sate lines. Dripping may be a sign of a blocked line.

Check that the condensate trap includes a water

seal.

e. Refer to Table 9. Check the temperature of both

supply and discharge water. If temperature is within

range, proceed with test. If temperature is outside

operating range, check cooling refrigerant pressures

LQ7DEOH9HULI\FRUUHFWZDWHUÀRZE\FRPSDULQJ

unit pressure drop across the heat exchanger versus

the data in Table 9. Heat of rejection can be calcu-

ODWHGDQGFRPSDUHGWRVSHFL¿FDWLRQFDWDORJ

f. Check air temperature drop across the coil when

compressor is operating. Air temperature should

drop between 15°F [8°C] and 25°F [14°C].

g. Turn thermostat to “OFF” position. A hissing noise

indicates proper functioning of the reversing valve.

6. Operate the heat pump in the heating cycle imme-

diately after checking cooling cycle operation. Allow

¿YHPLQXWHVEHWZHHQWHVWVIRUSUHVVXUHWRHTXDO-

ize or cycle the reversing valve to equalize.

a. Turn thermostat to lowest setting and set thermostat

switch to “HEAT” position.

b. Slowly turn thermostat to a higher temperature until

the compressor activates.

c. Check for warm air delivery at the unit grille within a

few minutes after the unit has begun to operate.

d. Check the temperature of both supply and discharge

water. Refer to Table 8. If temperature is within

range, proceed with test. If temperature is outside

operating range, check heating refrigerant pressures

in Table 8.

e. Check air temperature rise across the coil when

compressor is operating. Air temperature should

rise between 20°F [11°C] and 30°F [17°C]. Heat of

extraction can be calculated and compared to speci-

¿FDWLRQFDWDORJ

f. Check for vibration, noise, and water leaks.

7. If unit fails to operate, perform troubleshooting analysis

(CXM manual). If the check described fails to reveal the

problem and the unit still does not operate, contact a

trained service technician to ensure proper diagnosis and

repair of the equipment.

8. When testing is complete, set system to maintain desired

comfort level.

9. BE CERTAIN TO FILL OUT AND FORWARD

ALL WARRANTY REGISTRATION CARDS

TO HEAT CONTROLLER.

Note: If performance during any mode appears abnormal,

refer to the troubleshooting section of CXM manual. To obtain

maximum performance the air coil should be cleaned before

VWDUWXS$VROXWLRQRIGLVKZDVKHUGHWHUJHQWDQGZDWHULV

recommended.

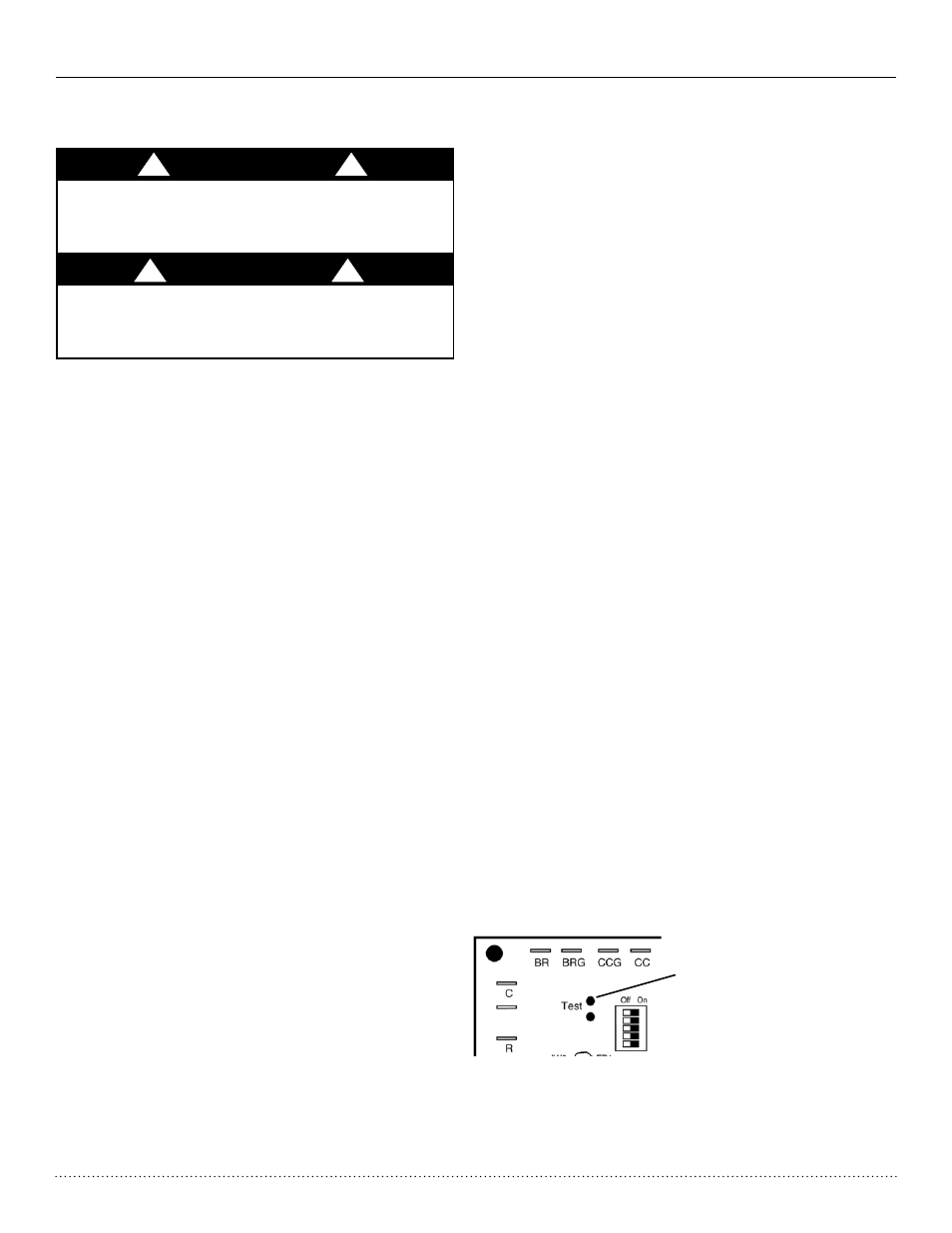

Short test pins together to

enter Test Mode and speed-

up timing and delays for 20

minutes.

Figure 14: Test Mode Pins

CXM Board

Unit Start Up Procedure

WARNING! When the disconnect switch is closed, high

voltage is present in some areas of the electrical panel.

Exercise caution when working with energized equipment.

INSTALLER CAUTION! After making water connections on

units equipped with ClimaDry, ensure the three union nuts

on the internal three-way water valve are tight.

WARNING!

!

!

CAUTION!

!

!