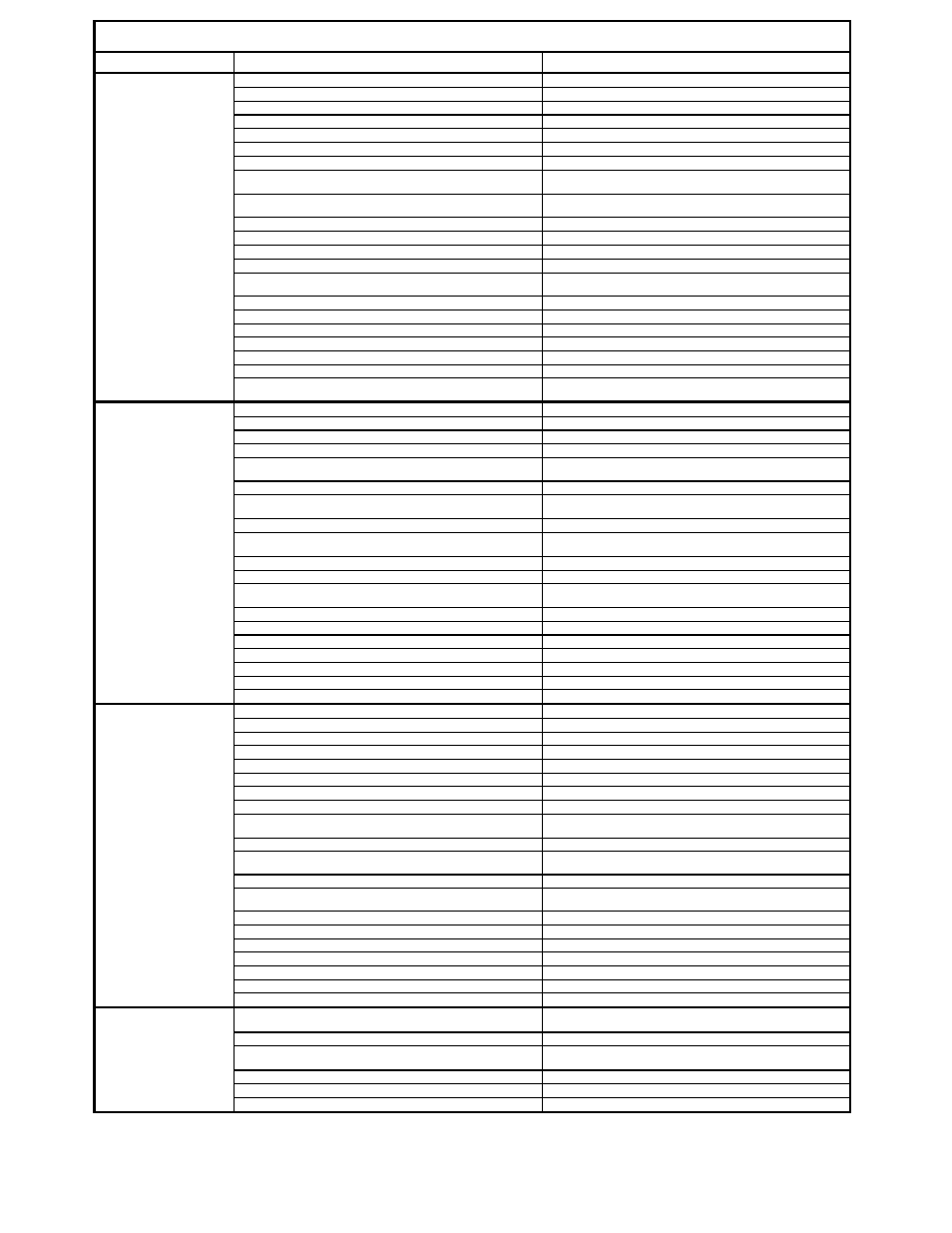

Table 3 (cont’d), Pump troubleshooting (cont’d) – Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 44

44 AF (42-66) IOM AF (42-66) IO

Pump Troubleshooting (Cont’d)

PROBLEM

PROBABLE CAUSE

REMEDY

Lubricant level

Be sure the oil level is at center line of sight glass

Improper lubricant

Check lubricant for suitability

Not lubricated enough

Increase frequency of grease lubrication

Broken or bent impeller vanes

Check impeller dimensions and vane layout

Excessive shaft misalignment

Check shaft run-out and consult factory

Inadequate lubricant cooling

Check pumpage temperature and add oil cooling system if necessary

Axial thrust or radial load higher than bearing rating

Calculate bearing life for make and model bearing

Bearings run hot and or fail on

a regular basis

Improper coupling lubrication

Check coupling lubrication schedule in manufacturers installation,

operation, maintenance manual

Coupling out of balance

Check pump and drive component vibration levels, rebalance coupling if

necessary

Suction pressure too high

Check liquid levels and static suction pressure

Bearing incorrectly installed

Check bearing orientation to sectional drawing

Impeller out of balance

Check pump vibrations, if necessary rebalance impeller

Excessive shaft deflection

Check shaft diameter, sag and deflection, consult factory

Pump run off design point

Check head and flow, AF’s should normally be run between 75% and

125% of BEP

Lubricant contamination

Inspect oil or grease for contaminants

Piping not properly anchored

Check to see if excessive pipe strain is being transferred to pump flanges

Pump and/or driver not secured to sub-base

Check fasteners, if loose check alignment and re-tighten

Specific gravity higher than specified

Analyze pumpage and compare to specified gravity

Viscosity higher than specified

Analyze pumpage and compare to specified viscosity

Pump assembled incorrectly

Compare pump assembly to instruction manual

Partly clogged impeller causing

Imbalance

Back flush pump or manually clean impeller

Broken or bent impeller or shaft

Replace as required

Pump foundation not rigid or sub-base not completely secured

Tighten hold down bolts on sub-base Check foundation rigidity

Impeller out of balance

Check impeller balance

Motor not secure

Check motor fasteners

Improper coupling lubrication

Check coupling lubrication schedule in manufacturers installation,

operation, maintenance manual

Bearing incorrectly installed

Check bearing orientation to sectional drawing

Coupling out of balance

Check pump and drive component vibration levels, rebalance coupling if

necessary

Pump operating speed too close to system’s natural frequency

Change speed to be +/- 20% of the pumps natural frequency

Pump is noisy or vibrates at

higher than normal levels

Impeller partly clogged

Back flush pump or manually clean impeller

Impeller clearances too tight

Check impeller clearances adjust if necessary

Pump assembled incorrectly

Compare pump assembly to instruction manual

Pump run off design point

Check head and flow, AF’s should normally be run between 75% and

125% of BEP

Excessive shaft deflection

Check shaft diameter, sag and deflection, consult factory

Worn bearings

Replace

Suction or discharge piping not anchored or properly supported

Anchor per Hydraulic Institute Strandards Manual recommendation

Suction and/or discharge valve closed or clogged

Open valves to remove partially blocked condition

Excessive shaft misalignment

Check shaft run-out and consult factory

Pump assembled incorrectly

Compare pump assembly to instruction manual

Pump is cavitating, insufficient NPSH available

System problem, increase liquid level or lower pump

Insufficient NPSH available

Increase liquid level or lower pump

Excessive shaft misalignment

Check shaft run-out and consult factory

Suction pressure too high

Check liquid levels and static suction pressure

Bearing installed incorrectly

Check bearing orientation to sectional drawing

Impeller out of balance

Check pump vibrations, if necessary rebalance impeller

Overheating of seal faces

Check flush flow with mfgr’s recommendation, increase if necessary

Excessive shaft deflection

Check shaft diameter, sag and deflection, consult factory

Lack of seal flush to seal faces

Check shaft diameter, sag and deflection, consult factory

High rate of mechanical seal

failure

Incorrect seal installation

Check seal materials vs. pumpage to determine compatibility

Pump is run dry

Fill system piping completely so the impeller is submerged

Pump run off design point

Check head and flow, AF’s should normally be run between 75% and

125% of BEP

Shaft/shaft sleeve worn

Replace shaft or shaft sleeve if necessary

Coupling out of balance

Check pump and drive component vibration levels, rebalance coupling if

necessary

Sub-base not installed correctly

Compare pump sub-base installation to instruction manual

Bearing failing

Replace if necessary

Piping not properly anchored

Check to see if excessive pipe strain is being transferred to pump flanges

Pump and/or driver not secured to sub-base

Check fasteners, if loose check alignment and re-tighten

Specific gravity higher than specified

Analyze pumpage and compare to specified gravity

Viscosity higher than specified

Analyze pumpage and compare to specified viscosity

Pump assembled incorrectly

Compare pump assembly to instruction manual

Head higher than rating. Reduced flow

Check for fouling in the piping or obstruction in discharge

Liquid heavier than expected

Check specific gravity and viscosity

Motor requires excessive

power

Incorrect rotation

Jog motor and check rotation

Pump run off design point

Check measured head and flow to specified head and flow

Stuffing box packing too tight

Readjust packing. Replace if worn

Rotating parts binding, internal clearances too tight

Check internal wearing parts for proper clearances

Table 3 (Cont’d)