Pump troubleshooting, Connection of sealing liquid, Table 3 – Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 43

AF (42-66) IOM 43

CONNECTION OF SEALING LIQUID

If stuffing box pressure is above atmospheric pressure

and the pumpage is clean, normal gland leakage of 40-

60 drops per minute is usually sufficient to lubricate and

cool packing and sealing liquid is not required.

NOTE: Otherwise an external flush should be used

to lubricate and cool packing.

An external sealing liquid is required when:

1. Abrasive particles in the pumpage could score

the shaft sleeve.

2. Stuffing box pressure is below atmospheric

pressure due to pump running when suction

source is under vacuum. Under these

conditions, packing will not be cooled and

lubricated and air will be drawn into the pump.

If an outside source of clean compatible liquid

is required,

The pressure should be 15-20 psi

(1.1-1.4 kg/cm

2

) above suction

pressure. The piping should be

connected to the stuffing box flush

port inlet.

3. Under extreme temperature and pressure a

pipe should also be connected to the flush

port outlet.

NOTE: Most packing requires lubrication. Failure

to lubricate packing may shorten the life of the

packing and pump.

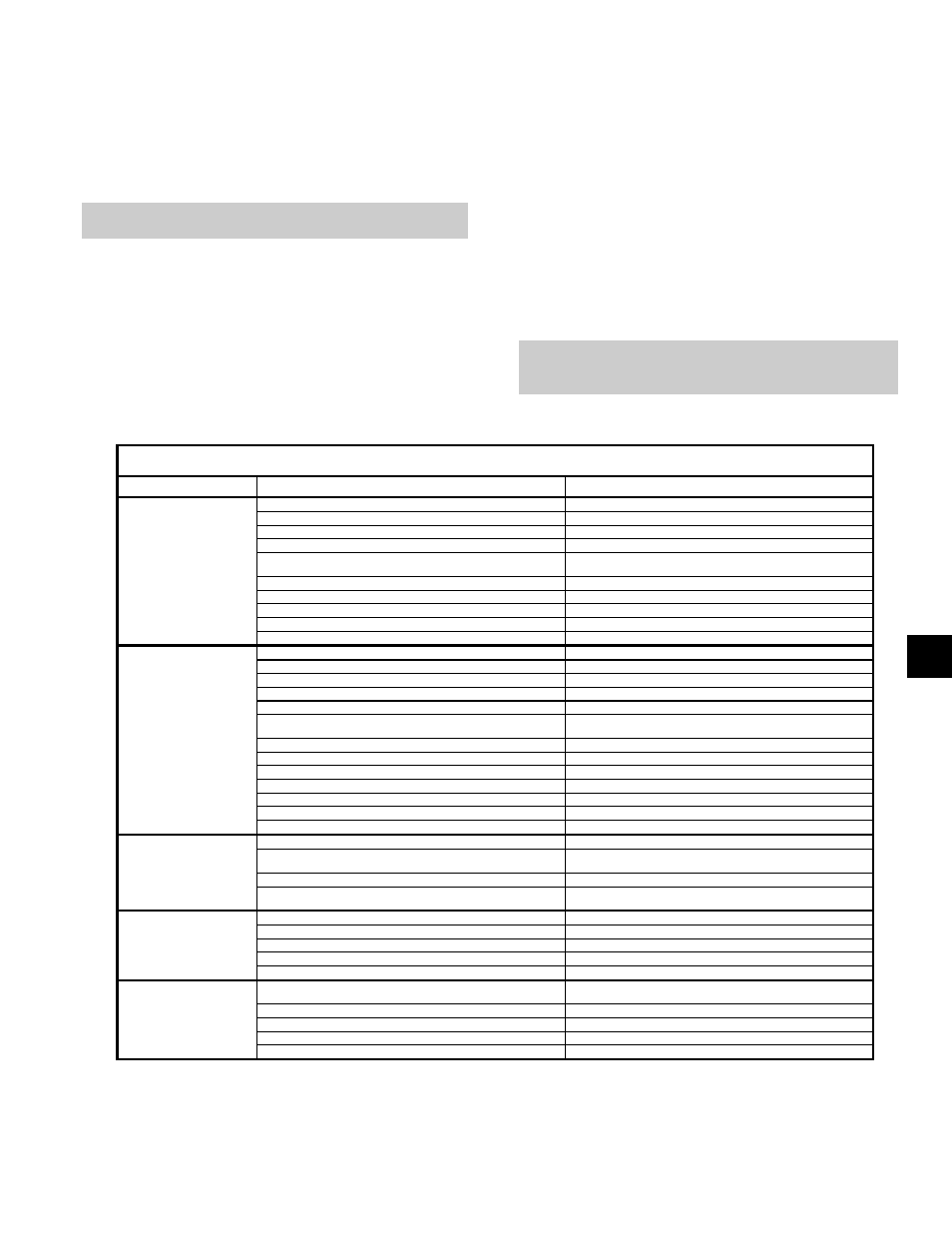

Pump Troubleshooting

PROBLEM

PROBABLE CAUSE

REMEDY

Pump not primed or prime lost, liquid level does not completely fill elbow Fill system piping completely so the impeller is submerged

Suction inlet clogged

Remove obstructions from pump inlet

Impeller clogged with foreign material

Back flush pump or manually clean impeller

Suction and /or discharge valve closed or clogged

Open valves to remove shut-off condition

No liquid delivered or

intermittent flow

Wrong direction of rotation

Change rotation to concur with direction indicated by the arrow on the

bearing housing

Suction piping incorrect

Replace or modify suction piping

Insufficient NPSH available

Increase liquid level or lower pump

Air leak in suction line

Test suction piping for leaks

Speed (rpm) too low

New drive or gear box to obtain higher pump speed

Excess air entrapped in liquid

Install vent in piping or eliminate air source

Impeller partly clogged

Back flush pump or manually clean impeller

Insufficient suction head

Fill system piping so the liquid level is above the pump impeller centerline

Pump not primed or prime lost, pump does not completely fill elbow

Fill system piping completely so the impeller is submerged

Suction and/or discharge valve closed or clogged

Open valves to remove partially blocked condition

Suction piping incorrect

Replace or modify suction piping

Pump not producing rated flow

or head

Excessive air entrapped in liquid

Install vent in piping or eliminate air source

Speed (rpm) too low

New drive or gear box to obtain higher pump speed

Incorrect rotation

Check motor wiring

Incorrect impeller or impeller diameter

Check vane angles and/ or impeller clearances

System head too high

Check system curve calculations, reduce system resistance

Instruments give erroneous readings

Check and calibrate instruments, replace if necessary

Worn or broken impeller, bent vanes

Inspect and replace if necessary

Pump assembled incorrectly

Compare pump assembly to instruction manual

Insufficient NPSH available

Increase liquid level or lower pump

Wear of internal wetted parts

is accelerated

Chemicals in liquid other than specified

Analyze pumpage and correct or change pump wet end materials to suit

pumpage composition

Pump assembled incorrectly

Compare pump assembly to instruction manual

Higher solids concentration than specified

Analyze pumpage and correct or change pump wet end materials to

harder composition

Packing gland improperly adjusted

Tighten gland nuts

Excessive leakage

Stuffing box improperly packed

Check packing and re-pack box

from stuffing box

Worn mechanical seal parts

Replace worn parts

Overheating mechanical seal

Check lubrication and cooling lines

Shaft sleeve scored

Re-machine or replace as required

Pump run off design point

Check head and flow, AF’s should normally be run between 75% and

125% of BEP

Packing has short life

Shaft/shaft sleeve worn

Replace shaft or shaft sleeve if necessary

Packing gland not properly adjusted

Replace packing and readjust gland as specified in the operating manual

Packing not properly installed

Check packing manufacturer's instructions.

Pump not assembled correctly

Compare pump assembly to instruction manual

Table 3

5