Warning – Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 23

AF (42-66) IOM

23

1. Check Belt Fit - Regardless of the belt section

used, the belt should never be allowed to bottom

in the groove. This will cause the belts to lose

their wedging action and slippage can occur.

Sheaves or belts that permit such a condition to

occur should be changed.

2. Maintain Proper Belt Tension - Proper tension

is essential for long belt life. Improper tension

could cause belt fatigue and/or hot bearings.

3. Impeller Alignment after Belt Tensioning – If

the impeller was aligned prior to belt tensioning a

check should be made to determine that it is still

centered. An off center impeller may rub and

cause unnecessary pump damage. Belt Tension

will usually cause impeller misalignment opposite

the motor. Be sure to align or re-align in

accordance with the Impeller Alignment section

page 26.

The general method of tensioning belts is given

below, and should satisfy most drive requirements.

General Method:

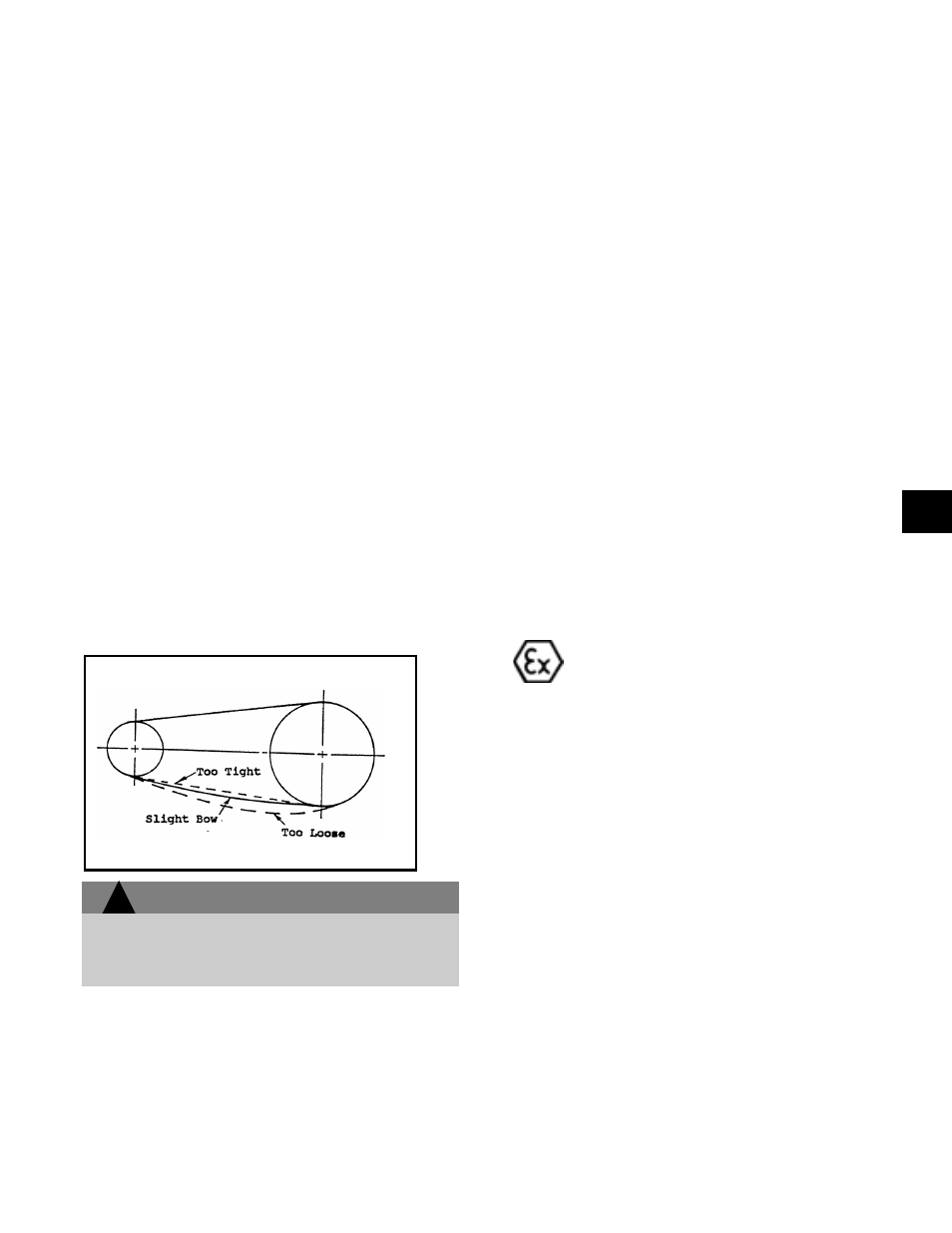

STEP 1. Reduce the center distance so that the belts

may be placed over the sheaves and in the grooves

without forcing them over the sides of the grooves.

Arrange the belts so that both belt spans have a

proximately the same sag between the sheaves.

Apply tension to the belts by increasing the center

distance until the belts are snug, see Fig. 13.

WARNING

Do not operate the pump without the proper drive

guard in place. Failure to observe this warning

could result in personal injury to operating

personnel

STEP 2. Operate the drive a few minutes to seat the

belts in the sheave grooves. Observe the operation of

the drive under its highest load condition (usually

starting). A Slight bowing of the slack side of the drive

indicates proper tension. If the slack side remains

taut during the peak load, the drive is too tight.

Excessive bowing or slippage indicates insufficient

tension. If the belts squeal as the motor begins

operation or at some subsequent peak load, they are

not tight enough to deliver the torque demanded by the

drive machine. The drive should be stopped and the

belts tightened.

STEP 3. Check the tension on a new drive frequently

during the first day by observing the slack side span.

After a few days of operation the belts will seat

themselves in the sheave grooves and it may become

necessary to readjust so that the drive again shows a

slight bow in the slack side.

Other methods of determining proper belt tension can

be obtained from the drive manufacturer.

5. Use Belt Guards - Belt guards protect personnel

from danger and the drive from contamination.

Inspect periodically to assure that belts do not rub

against guard.

6. Keep Belts Clean - Dirt and grease reduce belt life.

An occasional wiping with a dry cloth to remove any

build-up of a foreign material can extend the life of

the belt. Should oil or grease splatter onto the

belts, clean with soap and water.

Belt dressing affects performance only temporarily and

is never recommended. Maintaining a clean drive is a

better practice.

If any questions arise pertaining to the drive limitations,

consult the manufacturer.

GEAR DRIVE (COUPLINGS)

The coupling used in an ATEX classified

environment must be properly certified.

Remove the guard or guards by referring to the

assembly/disassembly instructions. Disconnect

motor/gearbox and the pump/gearbox coupling halves

before proceeding with the alignment. First, align the

pump/gearbox coupling then the motor/gearbox

coupling. Check both coupling connections for parallel

and angular alignment by either the Dial Indicator or

Straight-Edge Method outlined below.

Good alignment is achieved when the dial indicator

readings, for both parallel and angular misalignment,

are .003" (.076mm) Total Indicated Reading (T.I.R.) or

less when the pump and driver are at operating

temperature (Final Alignment). Fig. 14 describes what

to look for.

Fig. 13

!

3