Table 2 – Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 32

32 AF (42-66) IOM

4. Unlock driver power.

5. Make sure everyone is clear. Jog the driver just

long enough to determine direction of rotation.

Rotation must correspond to an arrow on bearing

housing.

6. Lock out power to driver.

7. Replace the V-belt guard.

CHECK IMPELLER CLEARANCE

Check impeller clearance before installing the pump.

The impeller must not rub when the shaft is turned by

hand, therefore it is recommended that the Impeller

Alignment Worksheet (shown on pg. 27) is filled out

and filed with the pump maintenance records for future

reference.

CHECK FOR FREE TURNING

Before the pump is started, rotate the pump by hand to

be sure it turns freely, and does not rub or bind.

BEARINGS

The bearing assembly uses spherical roller bearings to

carry the radial load, and a spherical roller thrust

bearing to carry the axial thrust load from the impeller.

The bearing housing has a horizontal split along the

centerline for ease of assembly and inspection.

LUBRICATION

The bearing uses oil bath lubrication. Oil lubricated

bearing assemblies are shipped without oil. Oil must be

added to the bearing housing before starting. Remove

the bearing housing breather (113A) and add oil until oil

level is at the center of the sight glass. If the unit has

an external oil lube system, fill the bearing housing and

the reservoir to satisfy the system requirements.

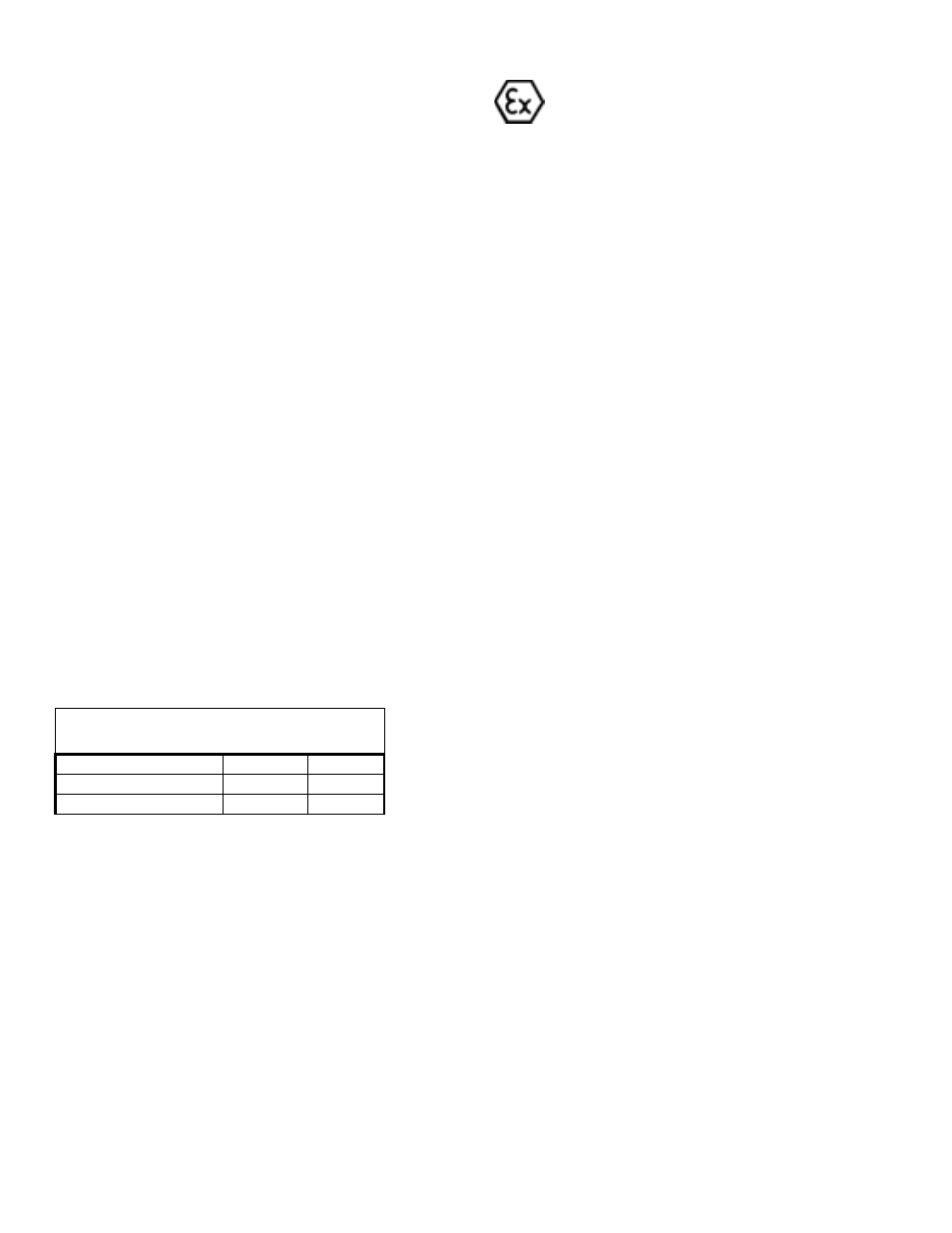

Replace the breather. Table 2.shows the oil volume

required.

Bearings must be lubricated properly in

order to prevent excess heat generation,

sparks and premature failure.

Run the pump for 1 minute to fill the oil galleys and in

and around each bearing. Check the sight glass and

add oil accordingly. Monitor the oil level indicator for

the first 24 hours of operation and maintain fill level.

OIL TYPE

Use an industrial quality lubrication oil such as Mobil

DTE series, Exxon Teresstic, or similar of ISO VG68.

ISO VG46 may be used in ambient temperatures

below 40F.

In any case the operating temperature viscosity must

be a minimum of 150SSU.

An oil with a higher viscosity than required will

increase the bearing operating temperature because

of the extra viscous drag, but never to the point where

the viscosity becomes lower than required from the

increased heat generation. It is therefore better for the

bearings to have an oil that is too heavy rather than

too light.

Change the oil after the first 200 hours of operation.

For normal operating conditions, change the oil at

least four (4) times a year. If the bearing assembly is

exposed to dirty or moist conditions, the oil should be

changed more often.

OIL LEVEL CONTROL

If the level of oil in the bearing housing (134C) is too

high, excessive heat may be generated due to

churning. If the level is too low, excessive heat may be

generated due to inadequate lubrication. A liquid level

switch connected to the oil sump can be used to warn

of a dangerous oil level condition.

Observe the oil level requirements shown on the

assembly drawing furnished with the pump. If

excessive heat is experienced within these levels,

consult the factory. Be sure that the shaft centerline is

horizontal through the bearing housing

NORMAL BEARING TEMPERATURE

The running temperature for a bearing assembly

depends on many factors such as speed, bearing

loads, lubrication, ambient air temperatures, and

condition of bearings. Temperatures higher than the

human hand can tolerate are very satisfactory for

good bearing operation and should not cause any

alarm.

For a given speed and loading, the bearing housing

temperature will stabilize at some temperature, usually

AXIAL FLOW PUMP

APPROX. OIL VOLUME

Pump Size

Quarts

Liters

42” / 1200mm / 54”

74

70.5

60” / 66”

62

59

Approximate values only. Always fill using sight glass to

verify level. Oil level should be at the center of the sight

glass. See comments in this section.

Table 2