Explosion prevention, Special atex considerations, General precautions – Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 4

AF (42-66) IOM

4

General Precautions

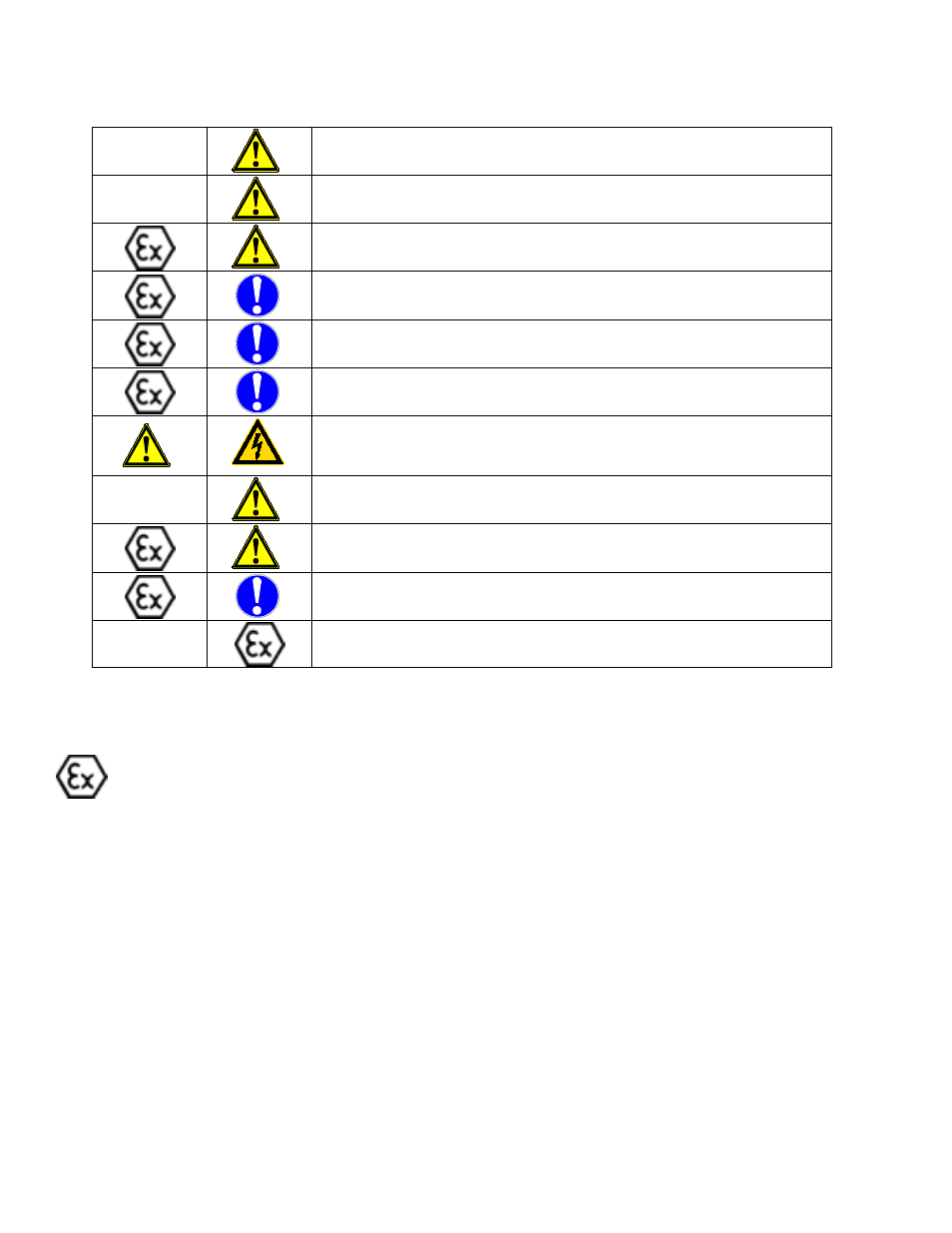

Explosion Prevention

In order to reduce the possibility of accidental explosions in atmospheres containing explosive gasses

and/or dust, the instructions under the ATEX symbol must be closely followed. ATEX certification is a

directive enforced in Europe for non-electrical and electrical equipment installed in Europe. ATEX

requirements are not restricted to Europe, and are useful guidelines for equipment installed in any

potentially explosive environment.

Special ATEX considerations

All installation and operation instructions in this manual must be strictly adhered to. In addition, care must be taken to

ensure that the equipment is properly maintained. This includes but is not limited to:

1. monitoring the pump frame and liquid end temperature

2. maintining proper bearing lubrication

3. ensuring that the pump is operated in the intended hydraulic range

Never apply heat to remove impeller. It may explode due to trapped

liquid

Never use heat to disassemble pump due to risk of explosion from

trapped liquid

Never operate pump without coupling guard correctly installed

Never operate pump beyond the rated conditions to which the pump was

sold

Never start pump without proper prime, or proper liquid level in self

priming pumps

Never run pump below recommended minimum flow or when dry

Always lock out power to the driver before performing pump maintenance

Never operate pump without safety devices installed

Never operate pump with discharge valve closed

Never operate pump with suction valve closed

Do not change conditions of service without approval of an authorized

Goulds representative