Pipe hung installation – Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 21

AF (42-66) IOM

21

PIPE HUNG INSTALLATION

LOCATION OF UNIT

The pump should be located in a clean, dry area free

from flooding. The area should provide adequate

space for maintenance and repair, considering

complete disassembly and handling of equipment.

The unit should be positioned to provide the most

efficient pipeline system.

PIPING

Short, direct suction and discharge pipelines having a

minimum of elbows and fittings will result in the least

amount of pipe friction. Excessive friction losses will

result in insufficient capacity and cavitation. Future

access to the pump impeller and shaft will require

removal of a section of discharge pipe (spool piece).

NOTE: The horizontal pipe flange must be parallel

with the pump flange before the bolts are

tightened. If the flanges are not parallel, forcing

them parallel by tightening the bolts may put

excessive strain on the pump.

INSTALLATION OF PUMP IN PIPELINE

1. Connect the pump top flange to the vertical

pipe and tighten flange bolts. Level pump

within .005” (0.42 mm)/Meter.

2. Check the impeller clearance in the casing so

that it is reasonably well centered using the

criteria that the minimum gap at the vane.

3. O.D. is at least 50% of the maximum gap (see

the impeller alignment worksheet, pg. 28 for

instructions)

4. Connect the casing flange to the spool piece

and tighten the flange bolts.

INSTALLATION OF THE DRIVER

Install the driver (motor and reduction gear on a

separate sub-base) as indicated on the installation

drawing for the pump. The universal joint drive shaft

requires the gear and pump shafts be parallel within 1

degree but off-set as indicated on the drawing. The

optimal universal joint life is obtained with off-set shaft

angles of 1 to 3 degrees.

Level the driver base relative to the pump, in

accordance with the proceeding paragraph using

leveling wedges adjacent to the anchor bolts. Partially

tighten the anchor bolt nuts and check the shaft

alignment between the motor and reduction gear. If the

alignment is reasonably satisfactory, grout the base in

place.

After the grout has hardened, tighten the anchor bolt

nuts. Check and correct the motor shaft alignment. We

recommend the actual shaft misalignment for the

flexible couplings be considerably less than the

maximum allowed by the coupling manufacturer for

long coupling life and reduced vibration levels.

CONNECTION TO PUMP DRIVER

The pipe hung pump is connected to the driver via a

drive shaft and universal joints at each end. Follow the

drive shaft installation instructions and the angle limits

per the pump installation drawing. An extendable guard

is provided for the drive shaft and should be used any

time the pump driver is rotating.

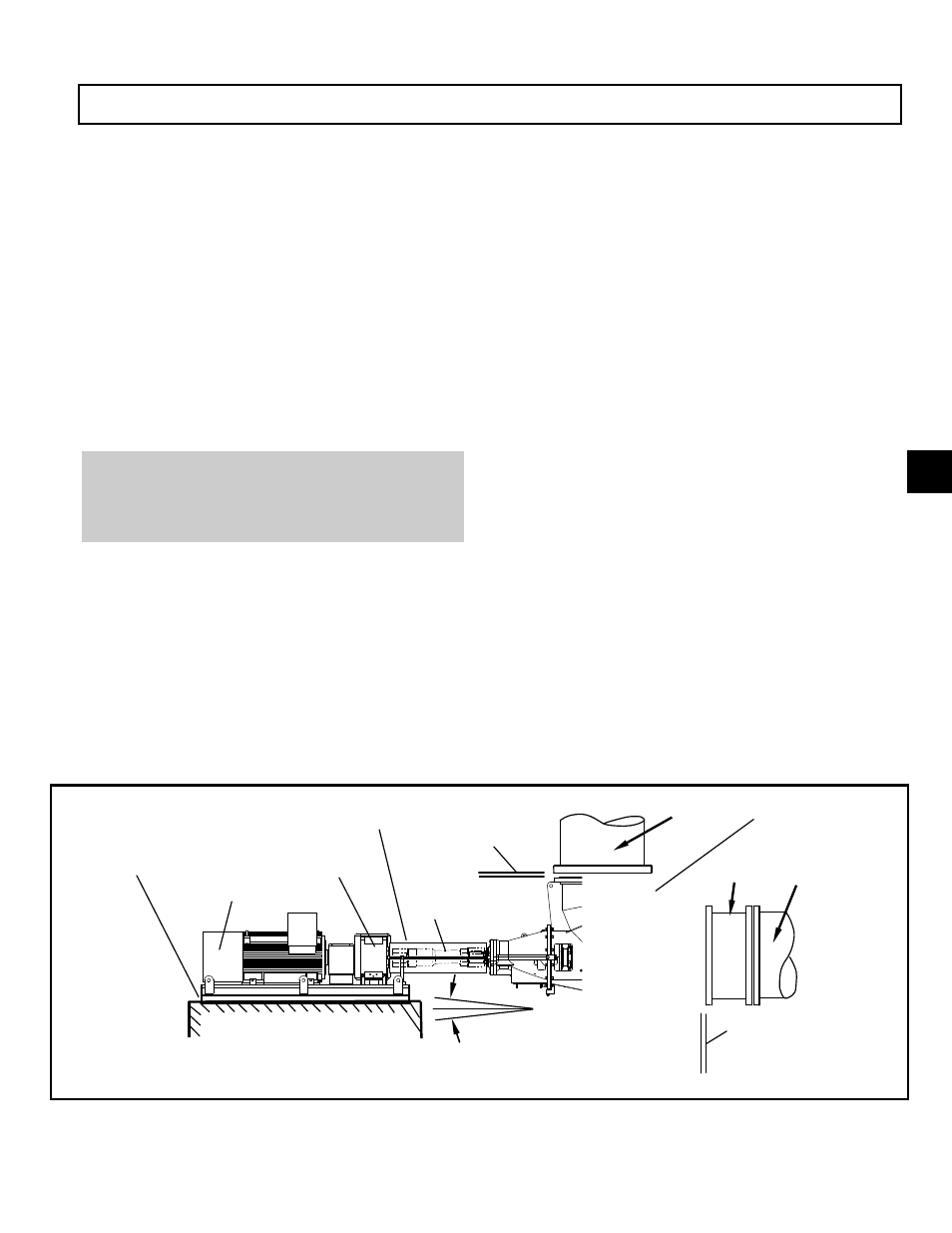

Fig. 11A

Foundation

Horizontal

Pipe

Vertical

Pipe

Spool Piece

Drive

Shaft

Motor

Reduction

Gear

Level Sub-base

Shaft Offset

+/- 1 to 3 deg.

Flanges must

be Parallel

Flanges must

be Parallel

Extendable

Guard

Pump must be

level .005”/ft

3