Goulds Pumps AF (Axial Flow) (42"/1200mm/54/60"/66") LM/LMR Bearings - IOM" User Manual

Page 33

AF (42-66) IOM

33

below 200

°F., which will be the normal temperature for

the installation.

temperature, without any change in speed or loading

can mean a lubrication difficulty or the approach of

bearing failure.

INSTALLING A BEARING

Long bearing life is dependent on careful handling of

the bearing when it is out of the housing and during the

installation procedure. Dirt and rough handling are

prime enemies of precision bearings. Bearings should

be pressed, not “hammered” into place. If heat is used

to facilitate the installation, a hot oil bath is the best

method.

THRUST BEARING ORIENTATION

Fig. 20 at the end of this section shows the axial thrust

bearing (112C) in the outboard location. This is used

for top suction pumps.

End suction pumps have the flow and axial thrust in

the opposite direction. Therefore, the complete thrust

bearing assembly is reoriented in the opposite

direction. This does not change the basic disassembly

procedure, other than the sequence of installing the

thrust bearing assembly components on the shaft.

The illustration shows the thrust bearing (112C)

mounted on a sleeve (196). For the other bearing

orientation, the bearing is mounted on an extension of

the spacer (443), eliminating the separate sleeve.

SHAFT SEALING

A packed stuffing box or mechanical seal is used to

seal the AF pump shaft. Both methods are described

below.

PACKED STUFFING BOX

The original equipment packing is a suitable grade for

the service intended. To pack the standard stuffing

box use the following procedure: For the special (6)

ring packing arrangement see the appendix 1.

1. Stuffing box and shaft sleeve must be clean and

free of grit.

2. Form packing over shaft or mandrel of same

diameter. Carefully cut to packing length. Discard

rings cut too short.

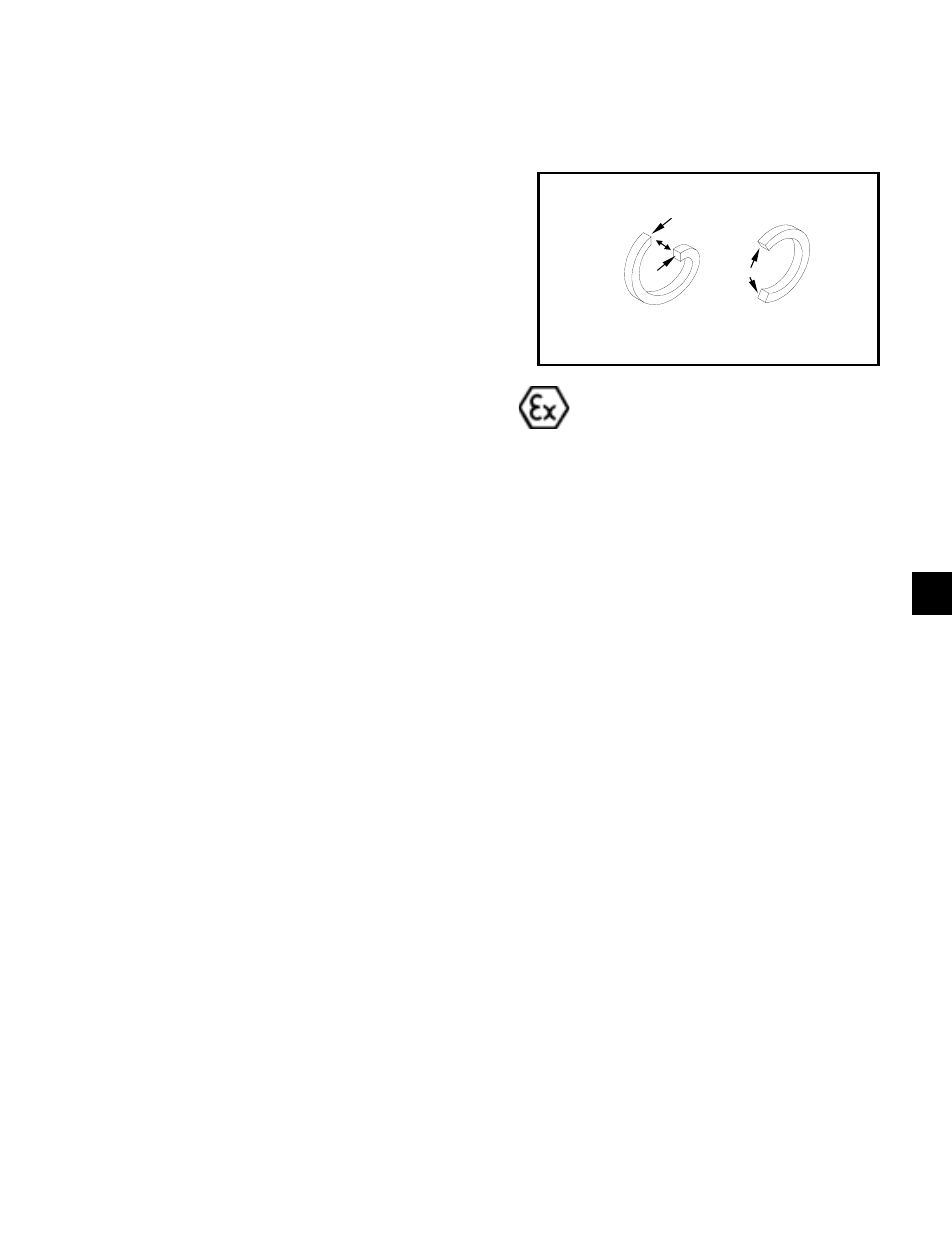

3. Pre-form each ring by coiling 1 -1 /2 turns.

4. To install packing rings, do not pull straight.

Expand the coil as a coil spring, see Fig 17 for the

correct and incorrect method of installing packing.

Expand the first coil as shown and insert into stuffing

box. Tamp packing to stuffing box shoulder firmly with

the gland. Note, where the cut is positioned.

5. Install the first lantern ring into the stuffing box.

Failure to property locate the lantern ring with the

flush port will result in insufficient packing

lubrication.

6. Install the second and third coil as required by

sectional drawing, staggering the cut 90

° to 120°.

7. Install the second lantern ring into stuffing box,

carefully noting its proper position on the sectional

drawing.

8. Install the third and fourth coil as required by

sectional drawing, staggering the cut 90

° to 120°.

9. After packing and lantern rings are properly

installed, insert gland into stuffing box. Tighten

gland nuts finger tight only. The shaft should turn

freely.

10. Turn lubricant supply on, start pump, and adjust

the gland as described in Section III-E Stuffing Box

Adjustment.

11. Periodic maintenance is absolutely required for all

packed pumps. Normal shaft run-out should be

under .005” to avoid pounding of stuffing box

packing. With excessive shaft run-out, shaft

straightening or replacement is necessary.

Packed stuffing boxes are not allowed in an

ATEX classified environment.

PACKING RINGS

CORRECT

INCORRECT

Fig. 17

4