Caution – Goulds Pumps 3408A - IOM User Manual

Page 42

NOTE: A locknut and lockwasher are not installed on

the inboard end of the pump shaft. It is acceptable to

leave the grease relief plug installed on the inboard

side for Step 22.

23. Repeat steps 15 through 22 for the inboard end.

IMPORTANT: Steps 15 through 25 and must be

completed within 10 to 12 minutes to assure proper

placement of the mechanical seal.

24. Reinstall the coupler on the end of the shaft.

25. Set the rotating element in the pump casing, assuring

correct rotation. Locate both stuffing box tongues in

their respective casing grooves. Locate the pins in the

stuffing box and the casing wear rings in their

respective slots at the casing parting surface. Correct

any O-ring bulging. See Figure 27.

$

!

CAUTION

DO NOT CUT OR DAMAGE THE O-RINGS WHEN

LOWERING THE ROTATING ELEMENT INTO

POSITION. WHEN ALL FOUR ANTI-ROTATION

PINS ARE LOCATED CORRECTLY, THERE WILL

BE SOME CASING RING LOOSENESS.

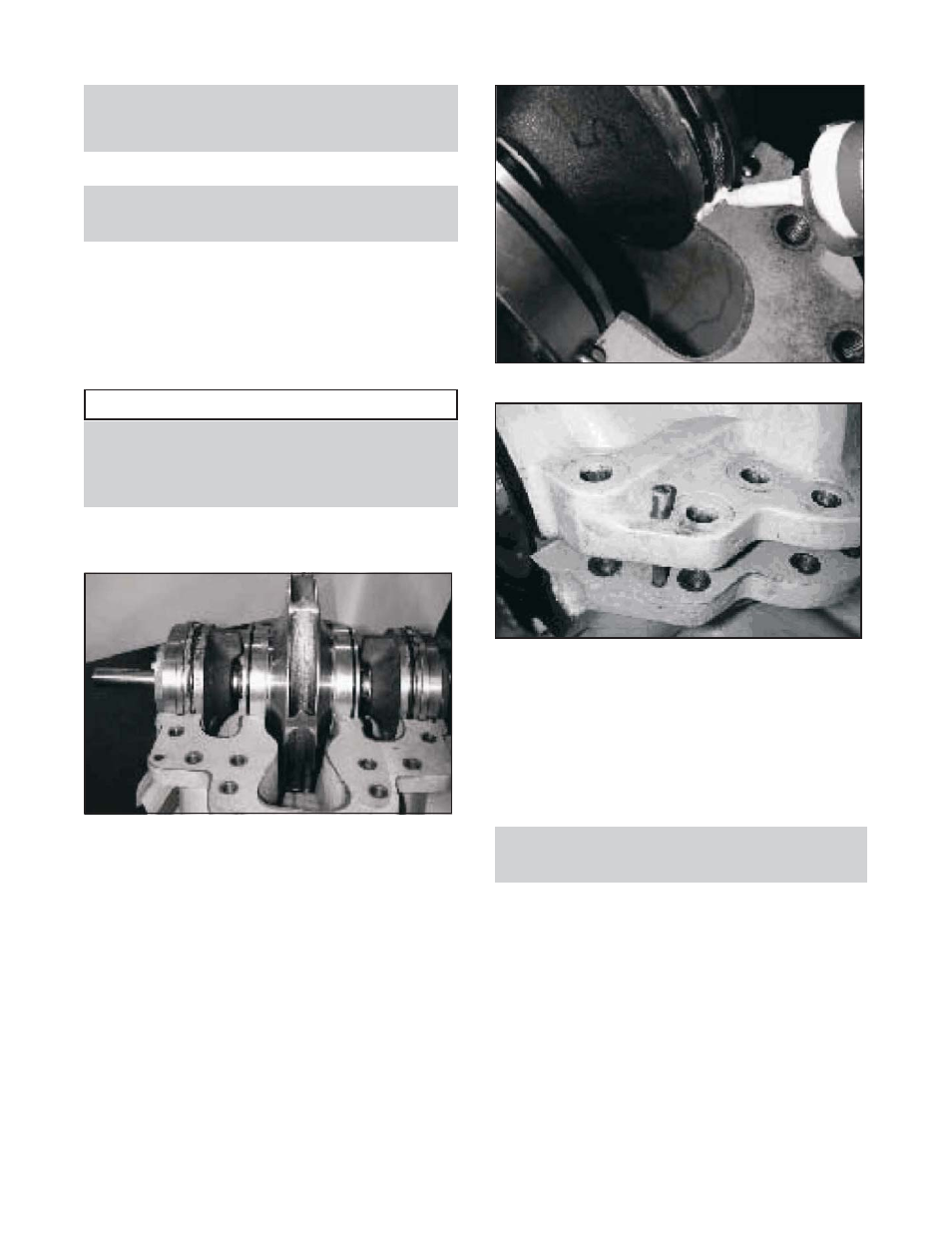

26. Apply a small bead of Dow Corning RTV silicone

sealant or equal at the parting line on top of gasket at

the stuffing box O-rings. See Figure 28.

Figure 27: Rotating element inside casing

Figure 28: Adding Sealant

Figure 29: Casing Main Joint

27. Locate the upper half of the casing into place using the

tapered dowel pins and install the casing main joint

bolts. See Figure 29. The casing joints should be

tightened to the following torques: 140 ft.-lb.

minimum for 5/8"-11 hex head cap screws (Grade 5);

350ft.-lb. minimum for 7/8"-9 Ferry Cap Counterbore

screws (Grade 8). Bolt torquing pattern is shown in

Figure 12.

NOTE: Torque values are essential in obtaining proper

gasket compression so no leakage can occur at the

main joint.

28. Rotate the shaft by hand to assure that it turns

smoothly and it is free from rubbing or binding.

29. Reinstall the coupler, check for alignment, and install

the coupler guard. See the sections entitled Alignment

Procedure and ANSI/OSHA Coupler Guard

Removal/Installation.

34

3408A IOM 6/08