Goulds Pumps 3408A - IOM User Manual

Page 35

REPLACING MECHANICAL SEALS

AND BEARINGS

(without removing the upper half of the casing)

NOTE: In order to replace the mechanical seal and

bearing housing on the coupler end, you must use a

spacer type coupler.

s

!

WARNING

Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in seri-

ous personal injury or death, or property damage.

$

!

CAUTION

Extreme Temperature Hazard

Allow pump temperatures to reach acceptable levels

before proceeding. Open the drain valve. Do not

proceed until liquid stops coming out of the drain

valve. If liquid does not stop flowing from the drain

valve, isolation valves are not sealing and should be

repaired before proceeding. After liquid stops flowing

from drain valve, leave the valve open and continue.

Remove the drain plug located on the bottom of the

pump housing. Do not reinstall the plug or closethe

drain valve until reassembly is completed.

Failure to follow these instructions could result in

moderate personal injury or property damage.

1.

Close valves on suction and discharge sides of pump.

If no valves have been installed, it will be necessary to

drain the system.

2.

Remove the coupler guard. For spacer coupler, loosen

the capscrews which secure the coupler flanges to the

coupler hubs. Remove the coupler flanges and sleeve

by compressing the flanges and pulling out from

beneath the hubs or by loosening the Allen set screws

and sliding the hubs back on the shafts. Remove the

coupler hubs from the pump shaft. For non-spacer

couplers, loosen set screws and slide flanges back on

shafts and remove rubber element.

3.

Remove the capscrews from each of the bearing

housings and remove the bearing housings by placing

two 2.0" long full-threaded capscrews or Allen set

screws in the jackscrew holes provided.

4.

Bend back the lockwasher tab and remove both the

lockwasher and locknut from the outboard end of the

shaft (the opposite side of the coupling).

5.

Remove the socket-head capscrews holding the gland

plates to the stuffing boxes.

6.

Insert threaded rods into the tapped holes in the gland

plate and install a fixture on the threaded rods to use a

puller. See Figure 14 for Dimensions of Universal

Fixture (PN: AC2394). Using the puller, tighten the

bolt in the center of the fixture to remove the bearing

and gland plate from the shaft. See Figures 15 and 16.

$

!

CAUTION

Pump Damage Hazard

Failure to remove the socket-head capscrews before

trying to pull the bearings off could cause damage to

the pump.

Failure to follow these instructions could result in

moderate personal injury or property damage.

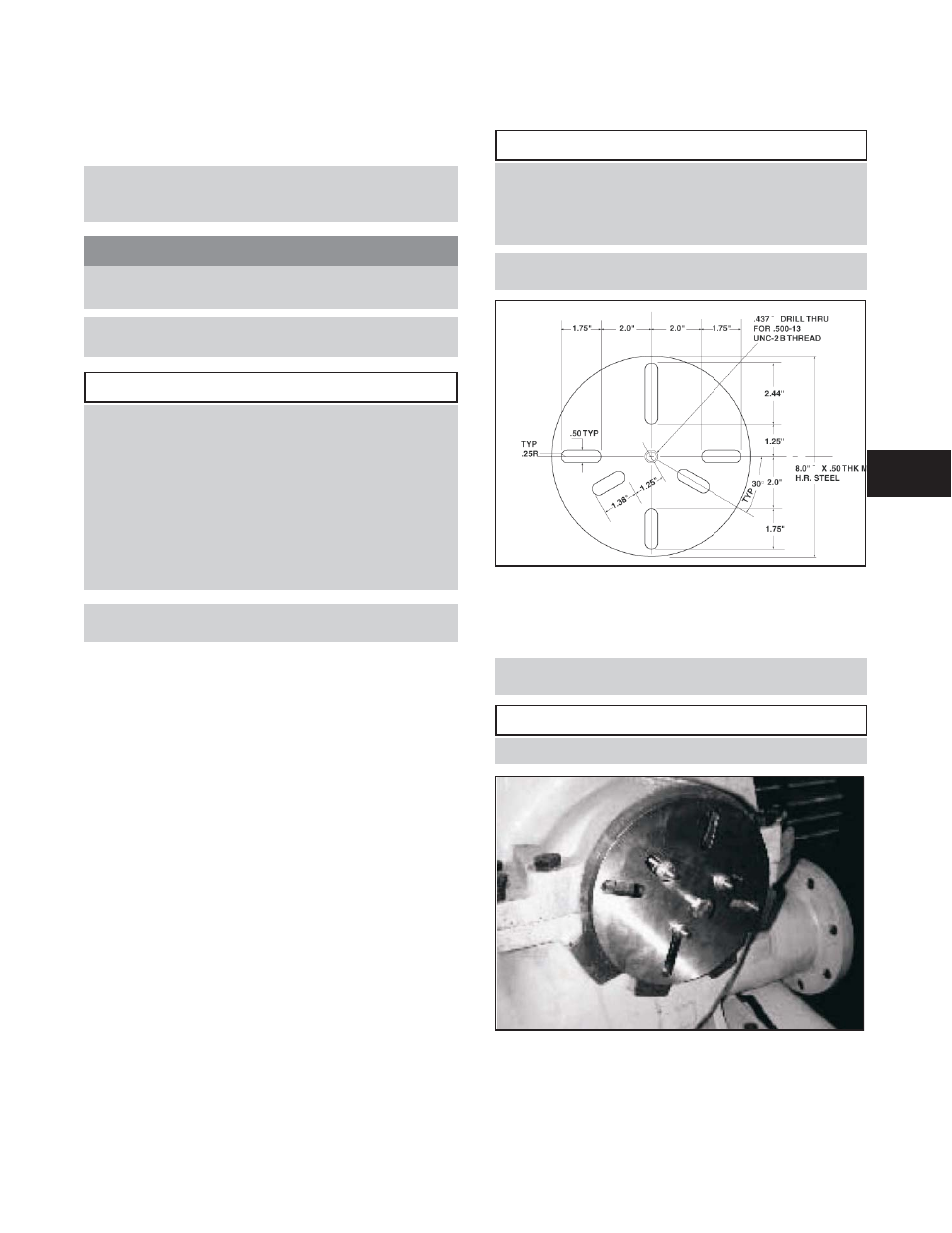

Figure 14: Dimensions for Universal Fixture

(PN: AC2394)

7.

Remove the inboard bearing and gland plate in the

same manner.

NOTE: The locknut and lockwasher are not used on

the inboard bearing.

$

!

CAUTION

Do not reuse the ball bearings

Figure 15: Removing bearing and gland plate

using universal fixture

3408A IOM 6/08

27

4