Caution – Goulds Pumps 3408A - IOM User Manual

Page 37

$

!

CAUTION

Use a flashlight and make sure the mechanical seal

spring is seated properly into the spring holder and

around the bellows of the mechanical seal before

continuing. Without properly seating the spring, the

seal will fail.

5.

Slide the gland plate, over the shaft, being very careful

that the head and the seat of the mechanical seal do not

get damaged. Then press the gland plate with the

O-ring into the stuffing box and tighten the

socket-head capscrews.

NOTE: Because of the compression of the O-ring, it

may be difficult to press the O-ring into the stuffing

box. Use longer socket-head capscrews to start the

gland plate into the stuffing box. Draw-up the bolts

evenly until the gland plate is secure in the stuffing

box. To prevent the mechanical seal spring from

pushing the gland plate back out of the stuffing box,

remove one long socket-head capscrew at a time and

replace with a regular sockethead capscrew.

6.

Heat the ball bearings using dry heat or 10% – 15%

soluble oil and water, or an induction heater.

$

!

CAUTION

Do not exceed a temperature of 275°F

7.

Fill up the lip seal cavity with approximately .50

ounces of grease.

8.

Using gloves, slide the heated bearing onto the shaft

against the shaft shoulder. See Figure 19.

Figure 19: Installing Bearing

9.

Install the locknut and lockwasher on the outboard end

of the shaft. Make certain that the locknut is secure and

bend over the tabs on the lockwasher. See Figure 20.

10. Allow the bearing to cool to room temperature. Coat

the exposed sides of the bearing with two or three

ounces of recommended grease. Drive as much grease

as possible into the bearing using a putty knife or

similar tool.

11. Remove the grease relief plug; coat the inside of the

bearing housing with grease, and then slide the

housing into place over the bearing. Alternately tighten

the bearing housing capscrews so as not to “cock” the

bearing housing causing bearing to bind. Leave the

grease relief plug out of the outboard housing until the

pump is run for a minimum of two hours and the

system has reached its normal operating temperature.

NOTE: A locknut and lockwasher are not installed on

the inboard end of the pump shaft. It is acceptable to

leave the grease relief plug installed on the inboard

side for Step 11.

12. Repeat steps 1 through 11 for the inboard.

13. Reinstall the coupler, check for alignment, and install

the coupler guard. See the sections entitled Alignment

Procedure and ANSI/OSHA Coupler Guard

Removal/Installation.

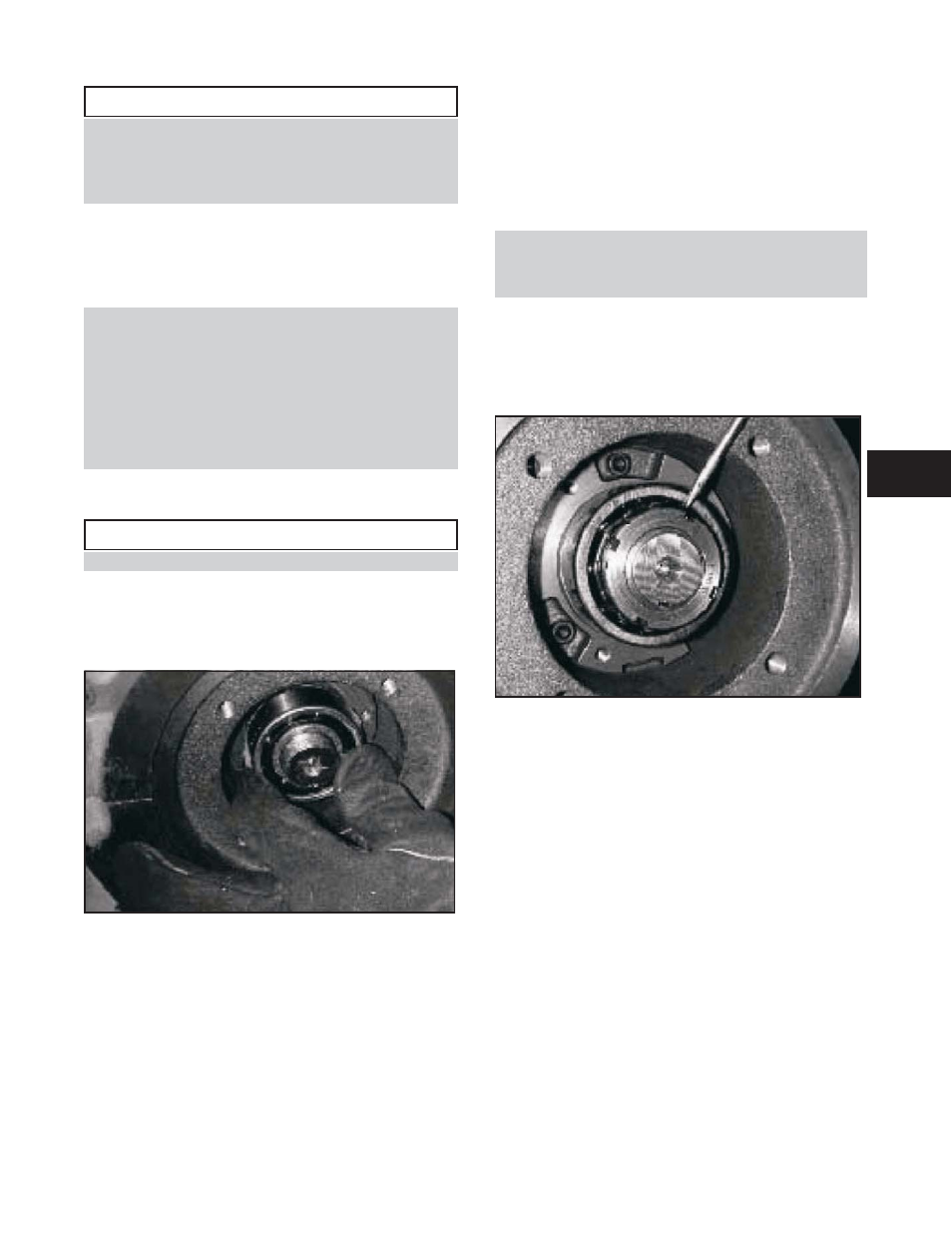

Figure 20: Installing Lockwasher and Locknut

3408A IOM 6/08

29

4