Goulds Pumps 3408A - IOM User Manual

Page 24

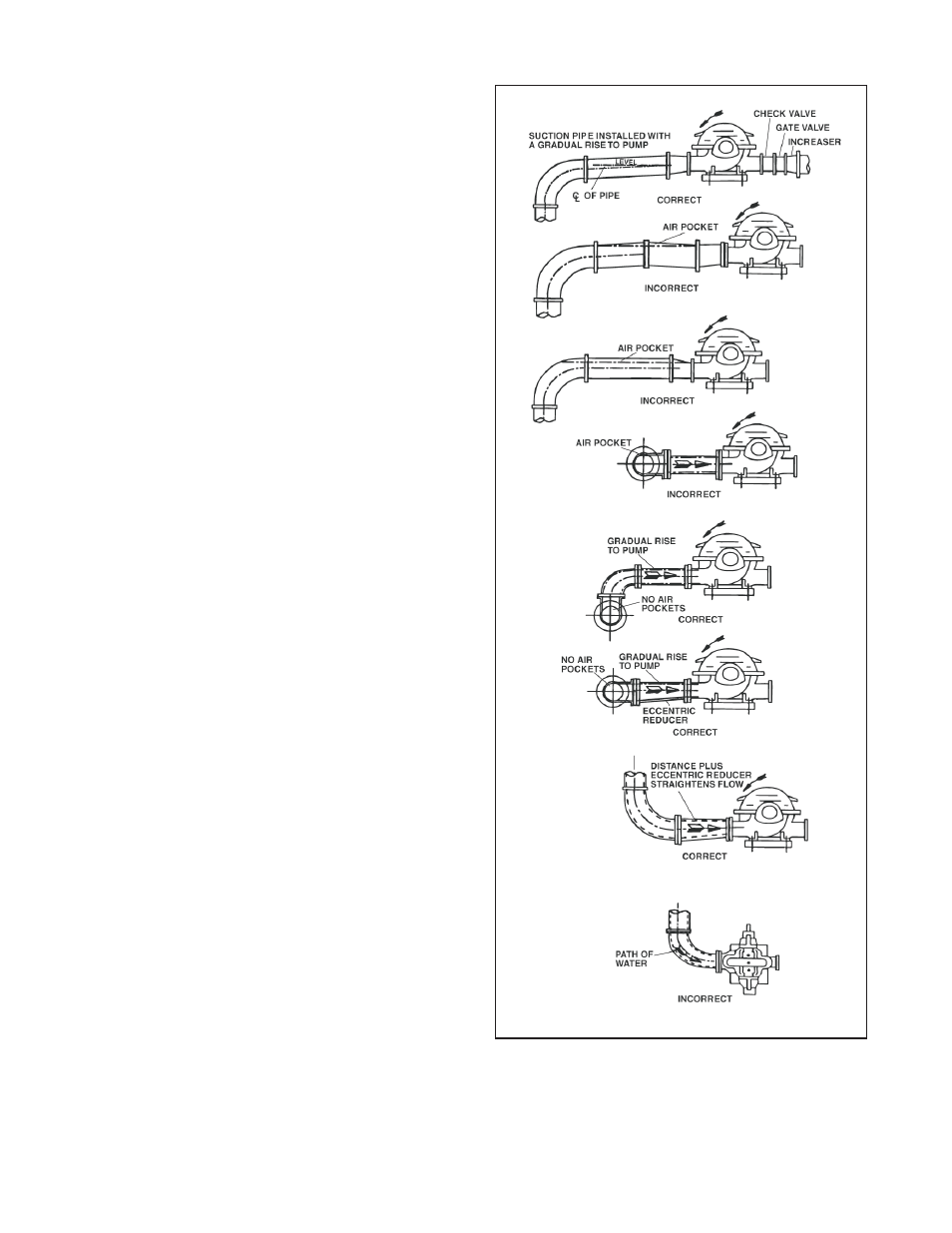

Suction Piping

When installing the suction piping, observe the

following precautions. See Figure 9.

The sizing and installation of the suction piping is

extremely important. It must be selected and

installed so that pressure losses are minimized and

sufficient liquid will flow into the pump when

started and operated. Many NPSH (Net Positive

Suction Head) problems can be attributed directly

to improper suction piping systems.

Friction losses caused by undersized suction piping can

increase the fluid’s velocity into the pump. As

recommended by the Hydraulic Institute, Standard

ANSI/HI 1.1-1.5-1994, suction pipe velocity should not

exceed the velocity in the pump suction nozzle. In some

situations pipe velocity may need to be further reduced to

satisfy pump NPSH requirements and to control suction

line losses. Pipe friction can be reduced by using pipes that

are one to two sizes larger than the pump suction nozzle in

order to maintain pipe velocities less than 5 feet/second.

Suction piping should be short in length, as direct as

possible, and never smaller in diameter than the pump

suction opening. If the suction pipe is short, the pipe

diameter can be the same size as the suction opening. If

longer suction pipe is required, pipes should be one or two

sizes larger than the opening, depending on piping length.

Suction piping for horizontal double suction pumps should

not be installed with an elbow close to the suction flange of

the pump, except when the suction elbow is in the vertical

plane. A suction pipe of the same size as the suction nozzle,

approaching at any angle other than straight up or straight

down, must have the elbow located 10 pipe diameters from

the suction flange of the pump. Vertical mounted pumps

and other space limitations require special piping.

There is always an uneven turbulent flow around an elbow.

When it is in a position other than the vertical it causes

more liquid to enter one side of the impeller than the other.

See Figure 10. This results in high unequalized thrust loads

that will overheat the bearings and cause rapid wear, in

addition to affecting hydraulic performance.

Figure 9: Suction Pipe Installations

(Piping supports not shown)

16

3408A IOM 6/08