Location – Goulds Pumps 3408A - IOM User Manual

Page 17

LOCATION

Locate the pump so there is sufficient room for inspection,

maintenance, and service. If the use of a hoist or tackle is

needed, allow ample head room.

s

!

WARNING

Falling Objects Hazard

Eyebolts or lifting lugs, if provided are for lifting only

the components to which they are attached.

Failure to follow these instructions could result in

serious personal injury or death, or property damage.

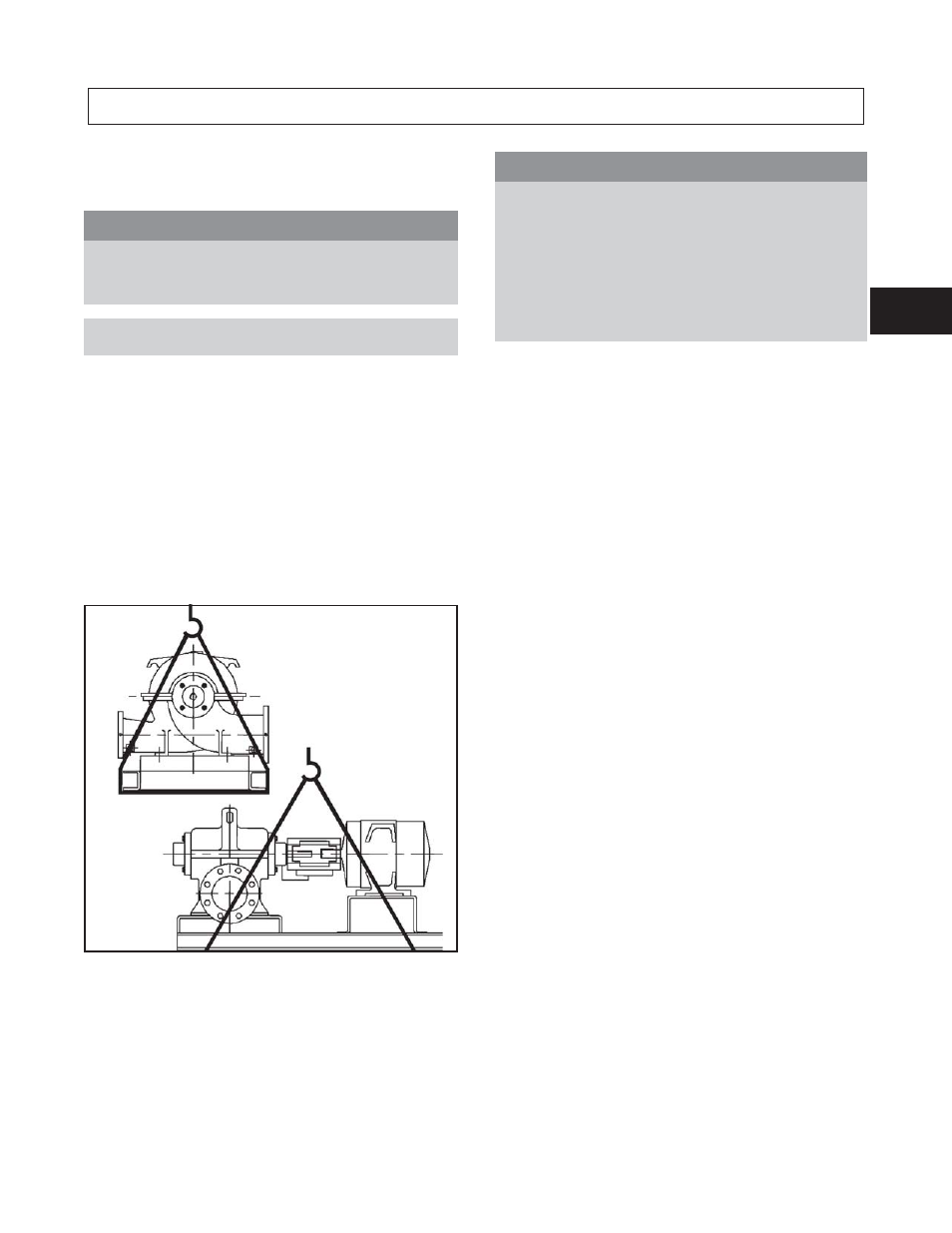

If lifting of the entire pump is required, do so with slings

placed under the base rails as shown in Figure 3.

The best pump location for sound and vibration absorption

is on a concrete floor with subsoil underneath. If the pump

location is overhead, special precautions should be

undertaken to reduce possible sound transmission. Consult

a sound specialist.

If the pump is not on a closed system, it should be placed as

near as possible to the source of the liquid supply and

located to permit installation with the fewest number of

bends or elbows in the suction pipe.

Figure 3: Lifting the Pump

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) meets or

exceeds the Net Positive Suction Head Required (NPSHR),

as stated by the pump performance curve. See the section

entitled Suction and Discharge Piping for more details

regarding proper suction piping installation.

s

!

WARNING

Do not install and operate pumps, 3D valves, suction

diffusers, etc., in closed systems unless the system is

constructed with properly sized safety devices and

control devices. Such devices include the use of

properly sized and located pressure relief valves,

compression tanks, pressure controls, temperature

controls, and flow controls as appropriate. If the

system does not include these devices, consult the

responsible engineer or architect before making pumps

operational.

3408A IOM 6/08

9

2