Goulds Pumps 3408A - IOM User Manual

Page 25

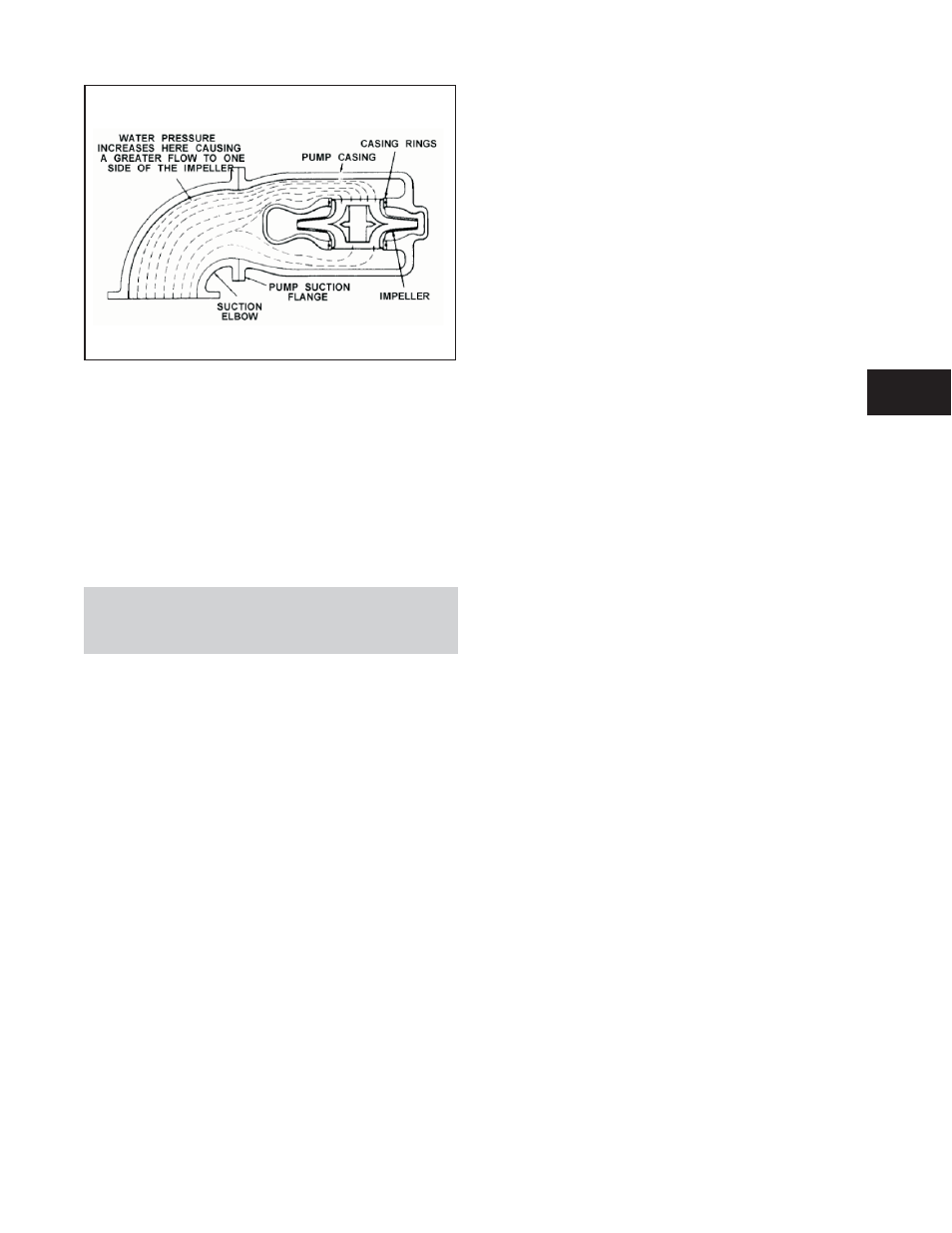

Figure 10:

Unbalanced loading of a double suction impeller due to

uneven flow around an elbow adjacent to the pump.

When operating on a suction lift, the suction pipe should

slope upward to the pump nozzle. A horizontal suction line

must have a gradual rise to the pump. Any high point in the

pipe will become filled with air and thus prevent proper

operation on the pump. When reducing the piping to the

suction opening diameter, use an eccentric reducer with the

eccentric side down to avoid air pockets.

NOTE: When operating on suction lift, never use a

straight taper reducer in a horizontal suction line, as it

tends to form an air pocket in the top of the reducer

and the pipe.

To facilitate cleaning pump liquid passage without

dismantling pump, a short section of pipe (Dutchman or

spool piece), so designed that it can be readily dropped out

of the line, can be installed adjacent to the suction flange.

With this arrangement, any matter clogging the impeller is

accessible by removing the nozzle or pipe section.

Valves in Suction Piping

When installing valves in the suction piping, observe

the following precautions:

a.

If the pump is operating under static suction lift

conditions, a foot valve may be installed in the

suction line to avoid the necessity of priming

each time the pump is started. This valve should

be of the flapper type, rather than the multiple

spring type, sized to avoid excessive friction in

the suction line. (Under all other conditions, a

check valve, if used, should be installed in the

discharge line. See the section entitled Valves in

Discharge Piping.

b.

When foot valves are used, or where there are

other possibilities of “water hammer,” close the

discharge valve slowly before shutting down the

pump.

c.

Where two or more pumps are connected to the

same suction line, install gate valves so that any

pump can be isolated from the line. Gate valves

should be installed on the suction side of all

pumps with a positive suction pressure for

maintenance purposes. Install gate valves with

stems horizontal to avoid air pockets. Globe

valves should not be used, particularly where

NPSH is critical.

d.

The pump must never be throttled by the use of

a valve on the suction side of the pump. Suction

valves should be used only to isolate the pump

for maintenance purposes, and should always be

installed in positions to avoid air pockets.

e.

A pump drain valve should be installed in the

suction piping between the isolation valve and

the pump.

Discharge Piping

If the discharge piping is short, the pipe diameter

can be the same as the discharge opening. If the

piping is long, pipe diameter should be one or two

sizes larger than the discharge opening. On long

horizontal runs, it is desirable to maintain as even a

grade as possible. Avoid high spots, such as loops,

which will collect air and throttle the system or lead

to erratic pumping.

Valves in Discharge Piping

A triple duty valve should be installed in the

discharge. The triple duty valve placed on the pump

protects the pump from excessive back pressure, and

prevents liquid from running back through the pump

in case of power failure.

Pressure Gauges

Properly sized pressure gauges should be installed in

both the suction and discharge nozzles in the gauge

taps, provided on request. The gauges will enable

the operator to easily observe the operation of the

pump, and also determine if the pump is operating in

conformance with the performance curve. If

cavitation, vapor binding, or other unstable

operation should occur, widely fluctuating discharge

pressure will be noted.

Pump Insulation

On chilled water applications most pumps are

insulated. As part of this practice, the pump bearing

housings should not be insulated since this would

tend to trap heat inside the housing. This could lead

to increased bearing temperatures and premature

bearing failures.

3408A IOM 6/08

17

3