Preventive maintenance, Troubleshooting – Goulds Pumps 3408A - IOM User Manual

Page 31

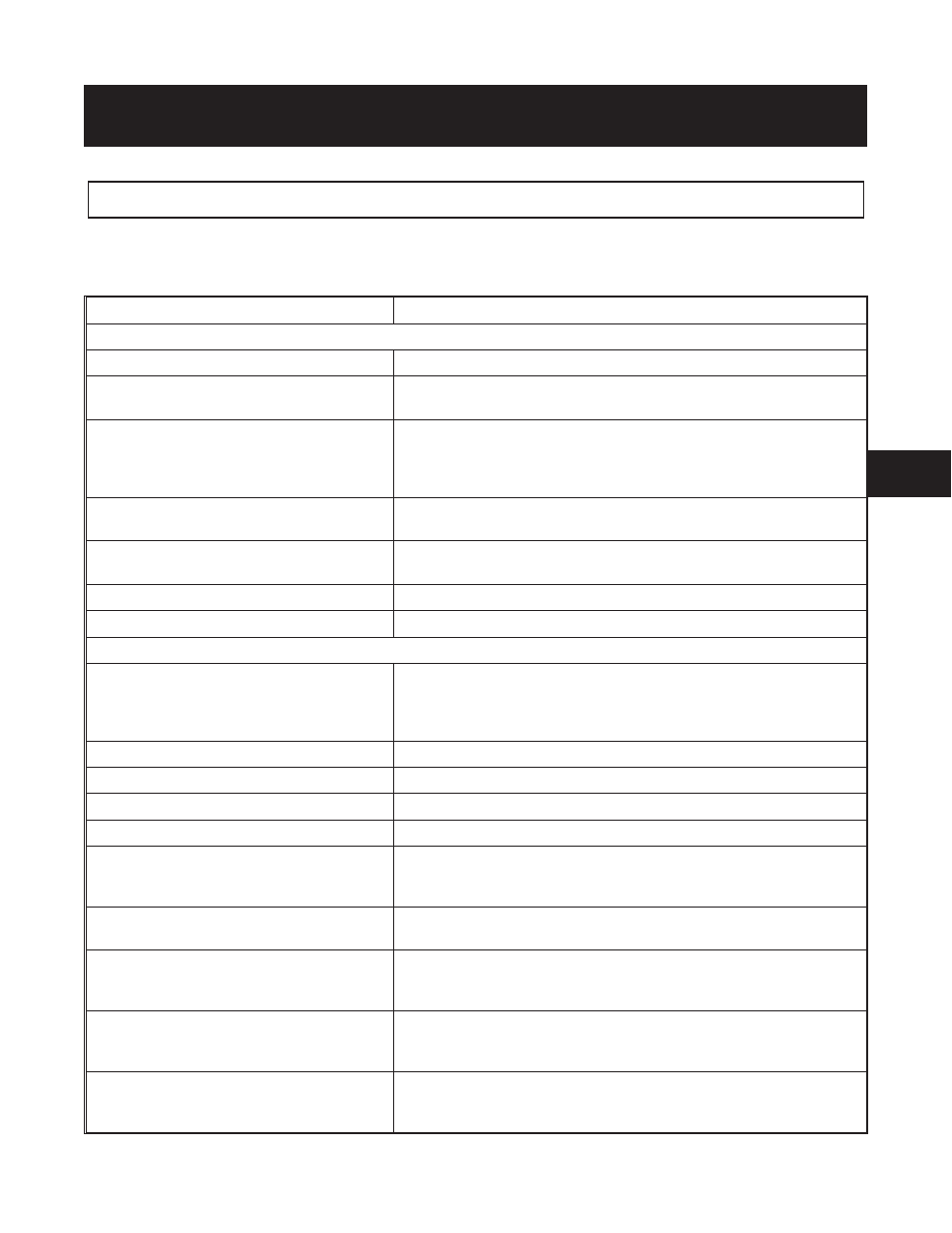

PREVENTIVE MAINTENANCE

TROUBLESHOOTING

Between regular maintenance inspections, be alert for signs of motor or pump trouble. Common symptoms are listed below.

Correct any trouble immediately and avoid costly repair and shutdown.

CAUSES

CURES

No Liquid Delivered

1. Lack of prime

Fill pump and suction pipe completely with liquid.

2. Loss of prime

Check for leaks in suction pipe joints and fittings; vent casing to remove

accumulated air.

3. Suction lift too high

If no obstruction at inlet, check for pipe friction losses. However, static

lift may be too great. Measure with mercury column or vacuum gauge

while pump operates. If static lift is too high, liquid to be pumped must be

raised or pump lowered.

4. Discharge head too high

Check pipe friction losses. Large piping may correct condition. Check

that valves are wide open.

5. Speed too low

Check whether motor is directly across-the-line and receiving full voltage.

Or frequency may be too low; motor may have an open phase.

6. Wrong direction of rotation

Check motor rotation with directional arrow on pump casing.

7. Impeller completely plugged

Dismantle pump and clean impeller. Not Enough Liquid Delivered

Not Enough Liquid Delivered

8. Air leaks in suction piping

If liquid pumped is water or other non-explosive, and explosive gas or

dust is not present, test flanges for leakage with flame or match, or by

plugging inlet and putting line under pressure. A gauge will indicate a

leak with a drop of pressure.

9. Speed too low

See item 5.

10. Discharge head too high

See item 4.

11. Suction lift too high

See item 3.

12. Impeller partially plugged

See item 7.

13. Cavitation; insufficient NPSH (depending

on installation)

a. Increase positive suction head on pump by lowering pump.b. Sub-cool

suction piping at inlet to lower entering liquid temperature.c.

Pressurization suction vessel.

14. Defective impeller

Inspect impeller, bearings and shaft. Replace if damaged or vane sections

badly eroded.

15. Foot valve too small or partially obstructed

Area through ports of valve should be at least as large as area of suction

pipe – preferably 1-1/2 times. If strainer is used, net clear area should be 3

to 4 times area of suction pipe.

16. Suction inlet not immersed deeply enough

If inlet cannot be lowered, or if eddies through which air is sucked persist

when it is lowered, chain a board to suction pipe. It will be drawn into

eddies, smothering the vortex

17. Wrong direction of rotation

Symptoms are an overloaded drive and about 1/3 rated capacity from

pump. Compare the rotation of the motor with the directional arrow on the

pump casing.

3408A IOM 6/08

23

4