Alignment method 1, Alignment method 2 – Goulds Pumps 3408A - IOM User Manual

Page 22

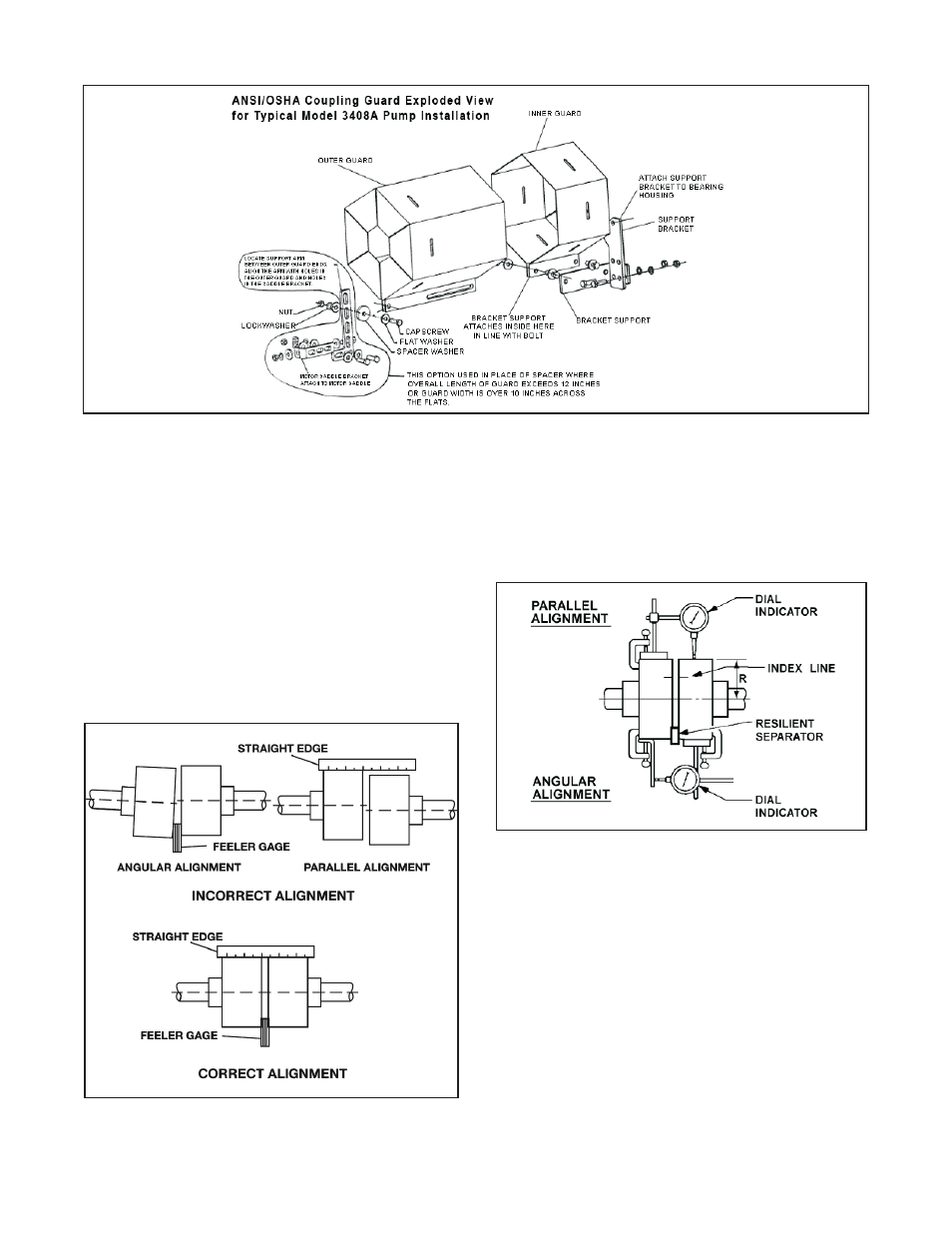

Figure 6: ANSI/OSHA Coupling Guard

Alignment Method 1

Straight Edge Alignment for Standard Sleeve Type Coupler

with Black Rubber Insert

See Figure 7.

Before aligning the coupler, make sure there is at least 1/8

inch end clearance between the sleeve and the two coupler

halves.

1.

Check angular misalignment using a micrometer or

caliper. Measure from the outside of one flange to the

outside of the opposite flange at four points 90° apart.

DO NOT ROTATE COUPLER. Misalignment up to

1/64 inch per inch of coupler radius is permissible.

Figure 7: Checking Alignment (Method 1)

2.

At four points 90° apart (DO NOT ROTATE

COUPLER), measure the parallel coupler

misalignment by laying a straight edge across one

coupler half and measuring the gap between the

straight edge and opposite coupler half. Up to a 1/64

inch gap is permissible.

Figure 8: Checking Alignment (Method 2)

Alignment Method 2

For Orange Hytrel Inserts, 3500 RPM Operation, or All

Other Coupler Types

See Figure 8.

1.

Make sure each hub is secured to its respective shaft

and that all connecting and/or spacing elements are

removed at this time.

2.

The gap between the coupling hubs is set by the

manufacturer before the units are shipped. However,

this dimension should be checked. Refer to the

coupling manufacturer’s specifications supplied with

the unit.

14

3408A IOM 6/08