Freeze protection, Caution, Changing rotation – Goulds Pumps 3408A - IOM User Manual

Page 28: Warning

FREEZE PROTECTION

Pumps that are shut down during freezing conditions

should be protected by one of the following methods.

1.

Drain the pump; remove all liquids from the casing.

2.

Keep fluid moving in the pump and insulate or heat the

pump to prevent freezing.

$

!

CAUTION

Bearing/Seal Damage Hazard

Do not let heated pump temperature rise above 150°F.

Failure to follow these instructions could result in

property damage and/or moderate personal injury.

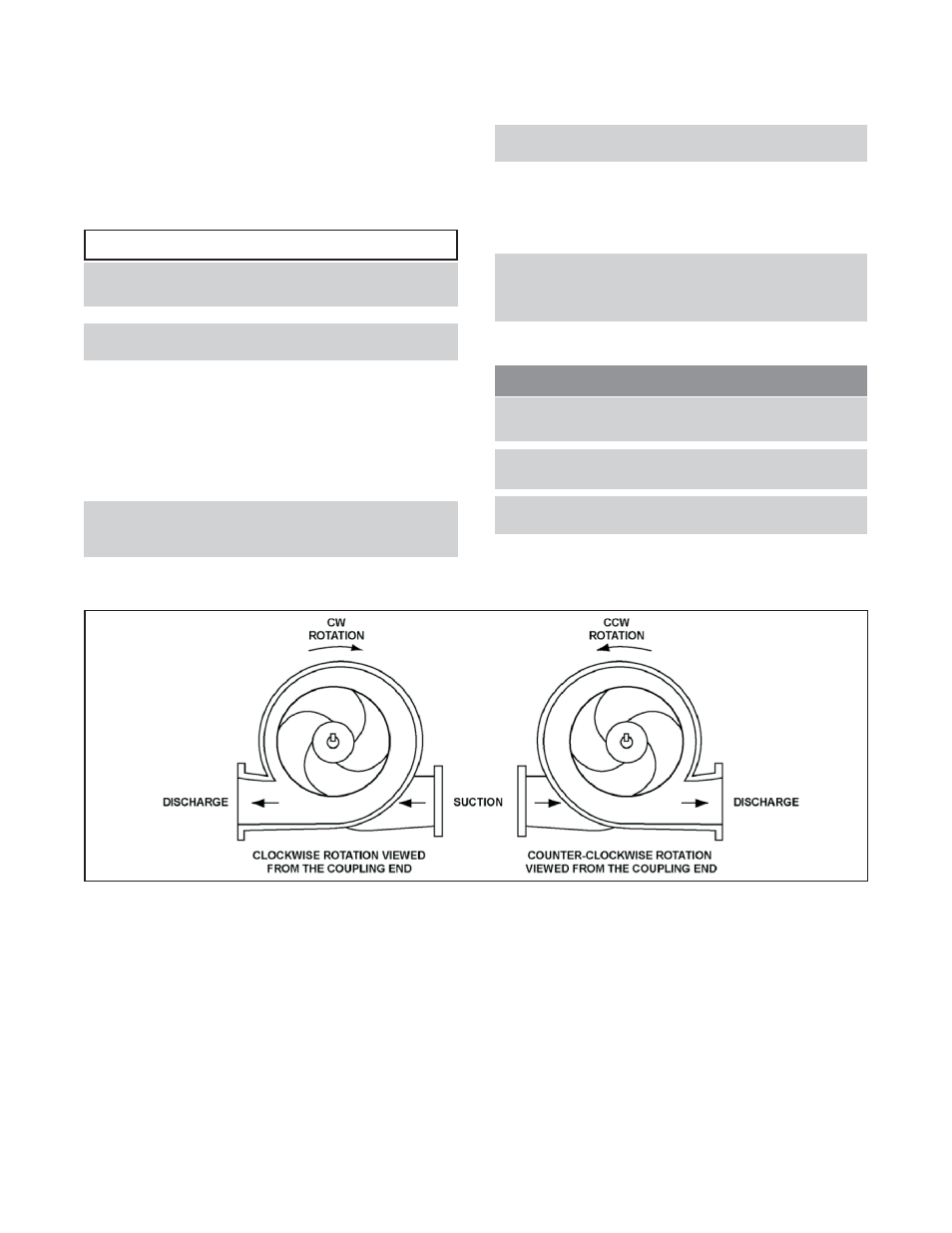

CHANGING ROTATION

3408A centrifugal pumps can be operated clockwise or

counterclockwise when viewed from the coupling end of

the pump. If you wish to reverse the suction and discharge

nozzles, this can be accomplished with the same pump as

follows:

IMPORTANT: Refer to the disassembly and assembly

procedures section of this manual for proper

disassembly and assembly techniques:

1.

Remove the impeller from the shaft, turn it 180° and

replace it on the shaft.

NOTE: The impeller can only come off from the

outboard end.

2.

With the rotating element out of the casing, remove the

casing from the bedplate and turn 180°.

3.

Set the rotating element back in the casing and

reassemble the pump.

NOTE: The impeller and casing are in the same

relationship to each other as they were originally. The

shaft and motor are also in the same relationship to

each other as they were originally.

4.

Reassemble pump and realign the coupling as called

for in the alignment instructions.

s

!

WARNING

Rotating Components Hazard

Do not operate pump without all guards in place.

Failure to follow these instructions could result in seri-

ous personal injury or death, or property damage.

NOTE: Unless the motor rotation is reversed, the

impeller will run backward.

Figure 11: Correct Relationship of Impeller and Casing

20

3408A IOM 6/08