Baseplate setting (before piping), Grouting procedure, Alignment procedure – Goulds Pumps 3408A - IOM User Manual

Page 20

shimmed and grouted.

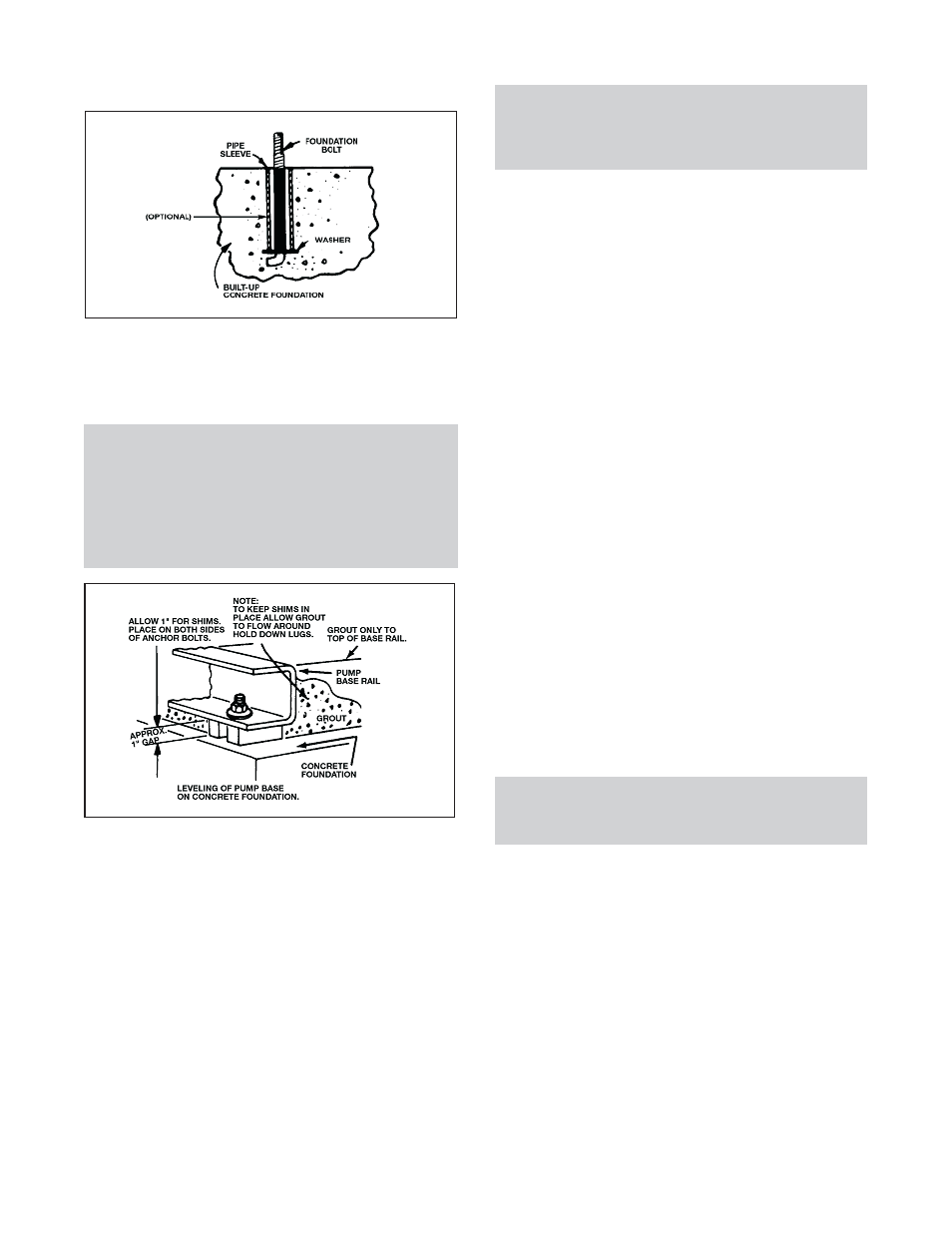

Figure 4: Foundation

BASEPLATE SETTING (BEFORE

PIPING)

NOTE: This procedure assumes that a concrete

foundation has been prepared with anchor or hold

down bolts extending up ready to receive unit. It must

be understood that pump and motor have been

mounted and rough aligned at the factory. If motor is

to be field mounted, consult factory for recommenda-

tions. Goulds Pumps cannot assume responsibility for

final alignment.

Figure 5: Setting Baseplate and Grouting

1.

Use blocks and shims under base for support at anchor

bolts and midway between bolts, to position base

approximately 1 inch above the concrete foundation,

with studs extending through holes in the baseplate.

2.

By adding or removing shims under the base, level and

plumb the pump shaft and flanges.

3.

Draw anchor nuts tight against base, and observe pump

and motor shafts or coupling hubs for alignment.

(Temporarily remove coupling guard for checking

alignment.)

4.

If alignment needs improvement, add shims or wedges

at appropriate positions under base, so that retightening

of anchor nuts will shift shafts into closer alignment.

Repeat this procedure until a reasonable alignment is

reached.

NOTE: Reasonable alignment is defined as that which

is mutually agreed upon by pump contractor and the

accepting facility (final operator). Final alignment

procedures are covered in the section entitled

Alignment Procedure.

5.

Check to make sure the piping can be aligned to the

pump flanges without placing pipe strain on either

flange.

6.

Grout in baseplate completely and allow grout to dry

thoroughly before attaching piping to pump. See the

section entitled Grouting Procedure. 24 hours is

sufficient time with approved grouting procedure.

GROUTING PROCEDURE

Grout compensates for uneven foundation, distributes

weight of unit, and prevents shifting. Use an approved,

non-shrinking grout, after setting and leveling unit. See

Figure 5.

1.

Build strong form around the foundation to contain

grout.

2.

Soak top of concrete foundation thoroughly, then

remove surface water.

3.

Baseplate should be completely filled with grout.

4.

After the grout has thoroughly hardened, check the

foundation bolts and tighten if necessary.

5.

Check the alignment after the foundation bolts are

tightened.

6.

Approximately 14 days after the grout has been poured

or when the grout has thoroughly dried, apply an oil

base paint to the exposed edges of the grout to prevent

air and moisture from coming in contact with the

grout.

ALIGNMENT PROCEDURE

NOTE: A flexible coupling will only compensate for

small amounts of misalignment. Permissible

misalignment will vary with the make of coupling.

Consult coupling manufacturer’s data when in doubt.

Allowances are to be made for thermal expansion during

cold alignment, so that the coupling will be aligned at

operating temperature. In all cases, a coupling must be in

alignment for continuous operation. Even though the

coupling may be lubricated, misalignment causes excessive

wear, vibration, and bearing loads that result in premature

bearing failure and ultimate seizing of the pump.

Misalignment can be angular, parallel, or a combination of

these, and in the horizontal and vertical planes. Final

alignment should be made by moving and shimming the

motor on the baseplate, until the coupling hubs are within

the recommended tolerances measured in total run-out. All

measurements should be taken with the pump and motor

foot bolts tightened. The shaft of sleeve bearing motors

should be in the center of its mechanical float.

12

3408A IOM 6/08