A1sp, A2sp, Al.re – NOVUS N480I User Manual

Page 2: Type, Dp.po, Vnit, In.ll, 1n.kl, 0ffs, A1fv

3

INSTALLATION

The indicator should be installed in a panel cut out as specified. First remove the mounting clamp and insert

the controller into the panel cut out. Place the unit into the panel cut-out and slide the mounting clamp from

the rear to a firm grip at the panel.

The internal circuitry can be fully removed from the housing without disconnecting any wiring. By using the

thumb just press the tab in the lower part of the front panel, grab firmly the front panel and pull out the

circuitry from the housing.

3.3

POWER

Mains power is connected to terminals 1 and 2. Check the upper side of the housing for proper power indication.

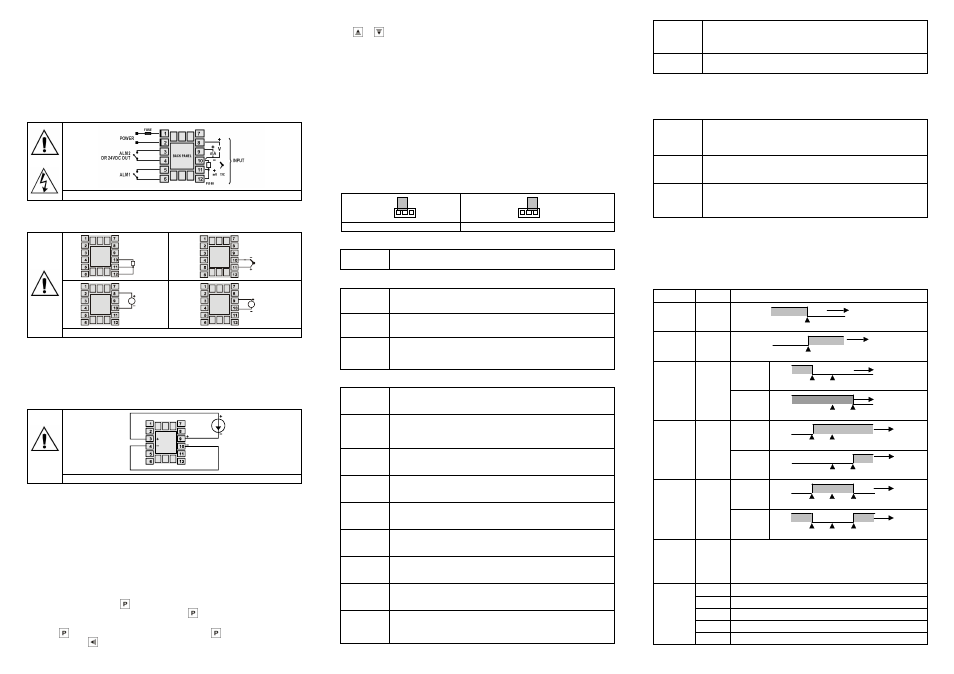

Figure 1 shows the electrical terminals of the indicator.

Figure 1 - Electrical connections

3.4

INPUT WIRING

The different input signals are connected according Figure 2.

Pt100

3-WIRE

T/C

V

VOLTAGE

mA

4-20mA

Figure 2 – Input Wiring

Notes:

1 For proper wire lenght compensation, all Pt100 wires should have the same electrical

resistance.

2

For 2 wire Pt100, short circuit terminals 11 and 12. Cable length is not compensated.

3

Thermocouples must be connected with the proper extension wire.

3.5

USING THE PROVIDED AUXILIARY DC VOLTAGE SUPPLY FOR POWERING 2-WIRE

FIELD TRANSMITTERS

Transmissor

2 fios

entrada 4-20mA

fonte de tensão

Figure 3 – 4-20 mA input wiring of a field transmitter powered by the N480i 24 V Auxiliary Power Supply

4

CONFIGURATION AND OPERATION

Prior to first operation the controller should be fully configured. The user must set basic parameters as

temperature type (“TYPE

TYPE

TYPE

TYPE”), the desired control set point (“SP

SP

SP

SP“), the alarms set points (“A1SP

A1SP

A1SP

A1SP” and “A2SP

A2SP

A2SP

A2SP”), etc.

4.1

PARAMETERS FLOW CHART

The programming parameters are organized in 4 different sets or levels:

Mensuration Level / Alarms Level / Configuration Level / Calibration Level

At power up the controller displays a prompt at the Operation Level and remains in this level while under

normal operation.

The other levels are only accessed when a change of parameters is necessary. To reach these other

parameters the user must keep the

key pressed for about three seconds. After this time the controller

will show the first parameter of the next level. By keeping the

key pressed for another 3 seconds the

next level will be accessed.

Release the

key when the desired level is reached. Press once the

key to go to the next prompt in

the same level. Use the

key to go back to the previous displayed parameter.

The upper display (red) shows the parameter name while the lower display (green) shows its value. The

keys

and

allow changing the parameter value.

The indicator will resume and show the operation level after all prompts have been accessed or whenever

the keyboard is not used for more than 20 seconds.

Any changed parameter is only saved into non-volatile memory after moving to the next parameter or when

no key is touched for 20 seconds.

4.2

PROGRAM SECURITY

To avoid tampering, parameter “Prot

Prot

Prot

Prot” and a hardware jumper can be used to disable access to

programming parameters.

With the jumper in the OFF position, all program levels are unprotected. The “Prot

Prot

Prot

Prot” parameter can only be

changed with the jumper in the OFF position.

With the jumper in the ON position or removed, the protection level is defined by the current value of the

“Prot

Prot

Prot

Prot” parameter:

0

0

0

0

No protection. All parameters can be accessed;

1

1

1

1

No access to the calibration level;

2

2

2

2

No access to calibration and configuration levels;

3

3

3

3

No access to calibration, configuration and tuning and alarms levels;

OFF

ON

Figure 4 – Protection Disabled

Figure 3 – Protection Enabled

4.3

OPERATION LEVEL

8888

After power up the indicator displays the measured valued proportional to the input

signal.

4.4

ALARMS LEVEL

A1SP

SP Alarm 1

SETPOINT for Alarm 1: Triping point for alarm 1

A2SP

SP Alarm 2

SETPOINT for Alarm 2: Triping point for alarm 2

AL.RE

Alarm

Reference

REFERENCE VALUE FOR DIFFERENTIAL ALARM: a value in respect to which

the differential, differential low and differential high alarms will be set.

4.5

CONFIGURATION LEVEL

TYPE

tYPE

INPUT TYPE: Selects the input sensor type to be connected to the indicator (refer

to Table 1). This is the first parameter to be set.

Dp.pO

Decimal Point

Position

DECIMAL POINT: Available only for input types 18, 19 or 20. Defines the number

of digits to be shown after the decimal point. Programmable from 0 to 3.

Vnit

unit

TEMPERATURE UNIT: Selects display indication for degrees Celsius or Farenheit.

0

0

0

0 – degrees Celsius ( °(

(

(

( ); 1

1

1

1 - degrees Farenheit ( °f

f

f

f );

in.ll

Input Low Limit

INPUT LOW LIMIT: Available for input types from 9 to 20. Defines the lowest value

to be displayed when the input signal is at its lower value. For input types from 0 to

8 it defines the lowest alarm set point value.

1n.kl

Input High Limit

INPUT HIGH LIMIT: Available for input types from 9 to 20. Defines the highest

value to be displayed when the input signal is at its upper value. For input types

from 0 to 8 it defines the highest alarm set point value.

0ffs

OFFSET

SENSOR OFFSET: Offset value to be added to the PV to compensate sensor

error. Default value: zero

A1fv

Alarm 1 Function

FUNCTION OF ALARM 1: Refer to Table 2 for function description and respective

codes to set at this prompt.

A2fv

Alarm 2 Function

FUNCTION OF ALARM 2: Refer to Table 2 for function description and respective

codes to set at this prompt.

Aiky

Alarm 1

HYsteresis

ALARM 1 HYSTERESIS: Defines the difference between the point at which the

alarm is activated and the point at which it is desactivated.

A2ky

Alarm 2

HYsteresis

ALARM 2 HYSTERESIS: Defines the difference between the point at which the

alarm is activated and the point at which it is desactivated.

Prot

PARAMETER PROTECTION: Refer to Table 2 for description of functions for this

prompt.

4.6

CALIBRATION LEVEL

A T E N T I O N

These parameters are used to calibrate the temperature measurement and should only be dealt with

by experienced and well equipped personnel.

Inl(

Input Low Calibration

SENSOR OFFSET CALIBRATION. Sets the temperature sensor low calibration

(offset). The display shows only the corrected temperature and not the offset added.

A signal simulator should be used to inject a low value signal to properly adjust the

offset.

InK(

Input High Calibration

INPUT HIGH CALIBRATION. Sets the sensor input circuit gain or high calibration.

A signal simulator should be used to inject a high value signal to properly adjust the

offset.

(j L

Cold Junction Low

Calibration

COLD JUNCTION OFFSET CALIBRATION: Sets the cold junction offset

calibration. A good thermometer or a temperature simulator should be used to

properly adjust this parameter.

5

ALARM FUNCTIONS

Low and high alarms are used to signal minimum and maximum temperature values as programmed in the

“A1SP

A1SP

A1SP

A1SP” and “A2SP

A2SP

A2SP

A2SP” prompts.

Differential alarms are used to indicate deviations from the desired set point (SP

SP

SP

SP) temperature.

These deviations are programmed at the “A1SP

A1SP

A1SP

A1SP” and “A2SP

A2SP

A2SP

A2SP” prompts.

Table 2 shows each alarm function operation with their respective code. Alarm 1 is used as an example.

TYPE

CODE

ACTION

LOW

0

0

0

0

SPA1

Alarm ON

Ligado

TEMPERATURE

HIGH

1

1

1

1

SPA1

Alarm ON

TEMPERATURE

A1

A1

A1

A1SP

SP

SP

SP

Negative

SP + SPA1

SP

Alarm

ON

TEMPERATURE

LOW

differential

2

2

2

2

A1

A1

A1

A1SP

SP

SP

SP

Positive

SP + SPA1

SP

Alarm ON

TEMPERATURE

A1

A1

A1

A1SP

SP

SP

SP

Negative

SP + SPA1

SP

Alarm ON

TEMPERATURE

HIGH

differential

3

3

3

3

A1

A1

A1

A1SP

SP

SP

SP

Positive

SP + SPA1

SP

Alarm

ON

TEMPERATURE

A1

A1

A1

A1SP

SP

SP

SP

Negative

SP - SPA1

SP + SPA1 SP

Alarm ON

TEMPERATURE

differential or

deviation

4

4

4

4

A1

A1

A1

A1SP

SP

SP

SP

Positive

SP + SPA1

SP - SPA1

SP

Alarm

ON

Alarm

ON

TEMPERATURE

Input sensor

error

5

5

5

5

Alarm is ON whenever:

•

Temperature is below selected range;

•

Temperature is above selected range;

•

Termocouple or Pt100 is broken;

•

Pt100 is shorted, badly connected or wire impedance is too high;

6

6

6

6

Low limit alarm disabled at power-up

7

7

7

7

High limit alarm disabled at power-up

8

8

8

8

Differential low limit alarm disabled at power-up

9

9

9

9

Differential high limit alarm disabled at power-up

Alarm Functions

With alarm

inhibition at

power-up

10

10

10

10

Differential alarm disabled at power-up

Table 2 - Alarm functions and their identification codes