NOVUS N1500G User Manual

Page 3

Indicator N1500G

NOVUS AUTOMATION

3/5

5.2.

ELECTRICAL CONNECTIONS

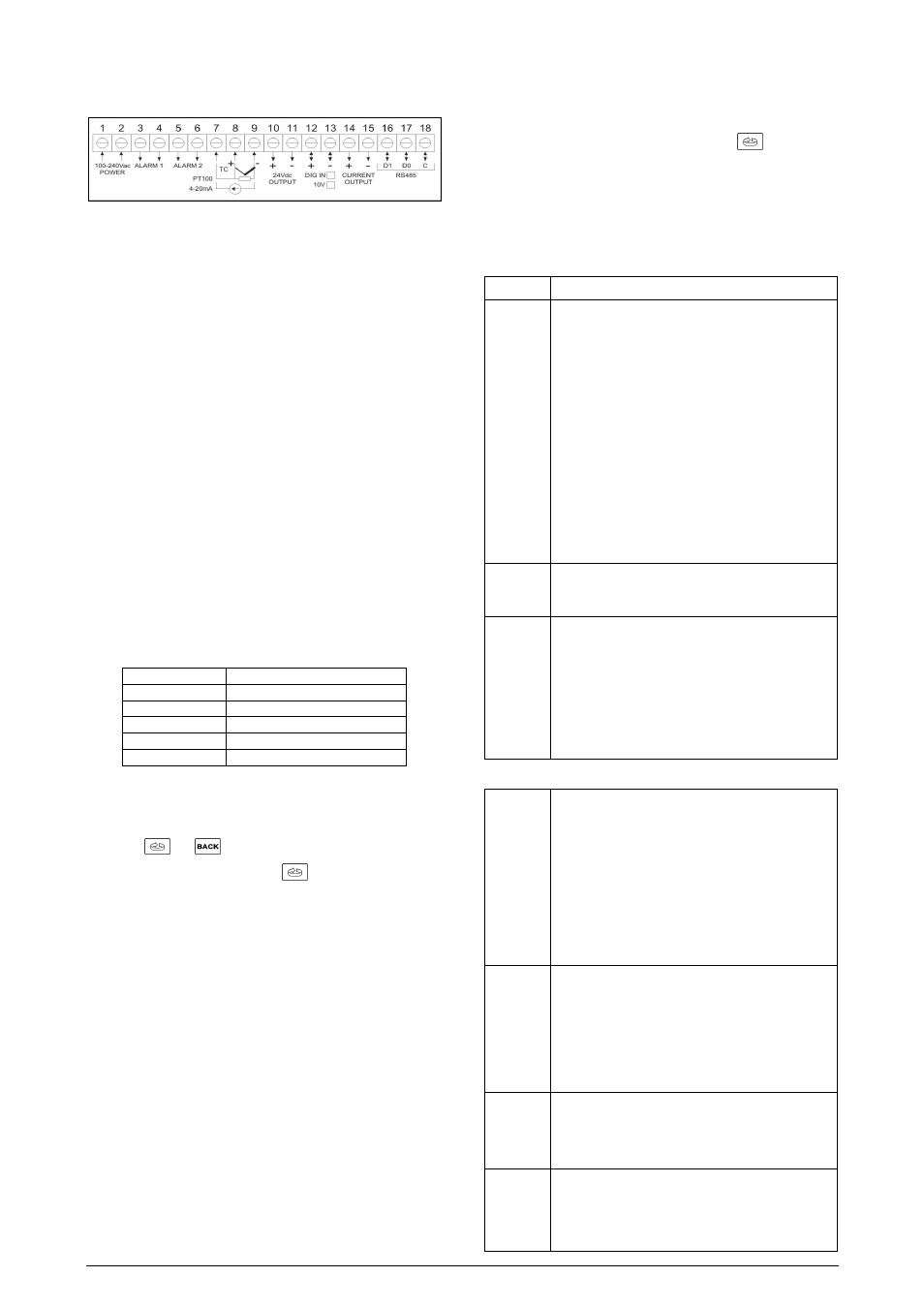

The internal electronics can be removed from the front panel without

any cable disassembly. The input signals and power connections are

shown in Figure 3.

Figure 3 - Back panel terminals

5.2.1.

Recommendations for Installation

•

Input signal wires should be laid out away from power lines and

preferably inside grounded conduits.

•

Instrument mains should be suitable for this purpose and wires

should not be shared with high consumption motors and inductors.

•

RC filters (47

Ω

and 100nF) are highly recommended for valve and

contactor coils, etc.

5.2.2.

Sensor or input signal connection

These connections should be properly done and terminals must be

well tightened. Thermocouples must be installed with proper

extension or compensation cables.

Pt100 RTDs must be 3-wire connected and the wires connected

should have the same electrical resistance (same wire gauge) for

correct cable length compensation. Four-wire RTDs can be

connected by disconnecting the fourth wire. Two-wire RTDs can be

connected by shortening terminals 7 and 8 and connecting the Pt100

to terminals 8 and 9.

6.

OPERATION

For best results this indicator requires correct setting of parameters

as input type (T/C, Pt100, 4-20 mA, etc), alarms actuation point,

alarm function, etc.

These parameters are divided in five levels or groups of parameters

which we will refer to as CYCLES.

Cycle

Access

1- Work

free access

2- Alarms

3- Functions

4- Configuration

reserved access

5- Calibration

Table 4 - Parameters Cycles

The work cycle has free access. All other cycles require a certain

combination of key strokes to be accessed. The combination is:

and

keys pressed simultaneously

Within a certain cycle just press

to go to the following

parameters. At the end of each cycle the display will go back to the

work cycle.

At the desired prompt just press the MAX or MIN key to change this

parameter accordingly.

All changes are recorded in non-volatile memory as we move to next

prompt. After 25 seconds with no key pressed the indicator will return

to the measuring cycle (work cycle).

6.1.

CYCLE PROTECTION

The values of parameters of a certain cycle can be protected against

non-authorized users.

The protected parameters can still be viewed but can not be

changed.

To protect a cycle just press the BACK and MAX keys for 3 seconds

at the beginning of the referred cycle. To unlock this cycle just press

the same keys again for 3 seconds.

The display will briefly blink confirming that the locking or

unlocking of the cycle.

7.

PROGRAMMING THE INDICATOR

7.1.

WORK CYCLE

This is the first and main cycle. At power up the indicator will display

the Process Variable (PV). The alarm setpoints are also displayed at

this cycle. To run through this cycle just press the

key.

Whenever an alarm is set with differential function the respective

alarm setpoint is blocked (SP.AL1, SP.AL2, ...) and the display

shows “diF” to advise the operator that this is a configuration

parameter and that the respective deviation value must be

programmed at the Alarms Cycle. The “AL.rEF” prompt will be

displayed showing the reference value for the alarm with differential

function.

TELA

PARAMETER DESCRIPTION

8.8.8.8.8.

Measure Shows the measured variable. For Pt100

or thermocouples the display will show the absolute

temperature value.

For 4-20 mA, 0-50 mV and 0-5 V inputs the display

shows the values defined in the in.LoL” and “in.HiL”

prompts.

With the hold function programmed the display

shows the frozen variable and alternates with the

message “HoLd”.

Likewise, with Peak Hold function programmed the

high limit is displayed with the “P.HoLd” prompt

alternately.

Should any fault situation occur the indicator will

display an error message which can be identified at

item 11 of this manual.

Al.ref

Differential Alarm Reference Value - This prompt

is shown only when there is an alarm programmed

with differential function.

Sp.al1

Sp.al2

Sp.al3

Sp.al4

Set Points of Alarms 1, 2, 3 and 4 - Defines the

operation point of each alarm programmed with “Lo”

or “Hi” function.

Note: When the alarms are programmed with

differential function, the alarm setpoint cannot be

changed at this cycle and a “diF” message will be

shown. The SP differential (deviation) value is set at

the Alarm Cycle.

7.2.

ALARM CYCLE

fV.al1

fV.al2

fV.al3

fV.al4

Alarm Function - Defines the alarms 1, 2, 3 and 4

function, as defined in item 4.1

oFF

: Alarm off

iErr

: Broken or Shorted Sensor

Lo

: Low value

Hi

: High value

DiFL

: Differential low

DiFH

: Differential high

DiF

: Differential

Df.al1

Df.al2

Df.al3

df.al4

Differential SP for Alarms 1, 2, 3 and 4 - Defines

the deviation value from the alarm setpoint in relation

to the Reference Value defined in the “ALdiF”

prompt.

Note: This value cannot be changed at this cycle for

alarms with non-differential function and the “AbS” is

then displayed.

Ky.al1

Ky.al2

Ky.al3

ky.al4

Alarm Hysteresis

This is the difference from the measured value to the

point where the alarm is turned ON and OFF.

Bl.al1

Bl.al2

Bl.al3

bl.al4

Alarm Blocking

Should any alarm condition occur, each alarm can

be disabled when energizing the indicator. Refer to

item 4.3.