Mechanical installation, Dimensions, Electrical installation – NOVUS TxBlock-USB Transmitter User Manual

Page 2: Recommended torque in the terminal: 0.8 nm, Recommendations for installation

TxBlock-USB

NOVUS AUTOMATION

2/4

During the setup, the transmitter is powered by the USB, not

requiring an external power supply.

The transmitter setup can also be made by connecting it to the loop,

using the loop power supply. There is no electrical insulation between

the transmitter and the communication port (interface), therefore it is

not recommended to configure it with the sensor inlet connected to the

process. See Fig. 2.

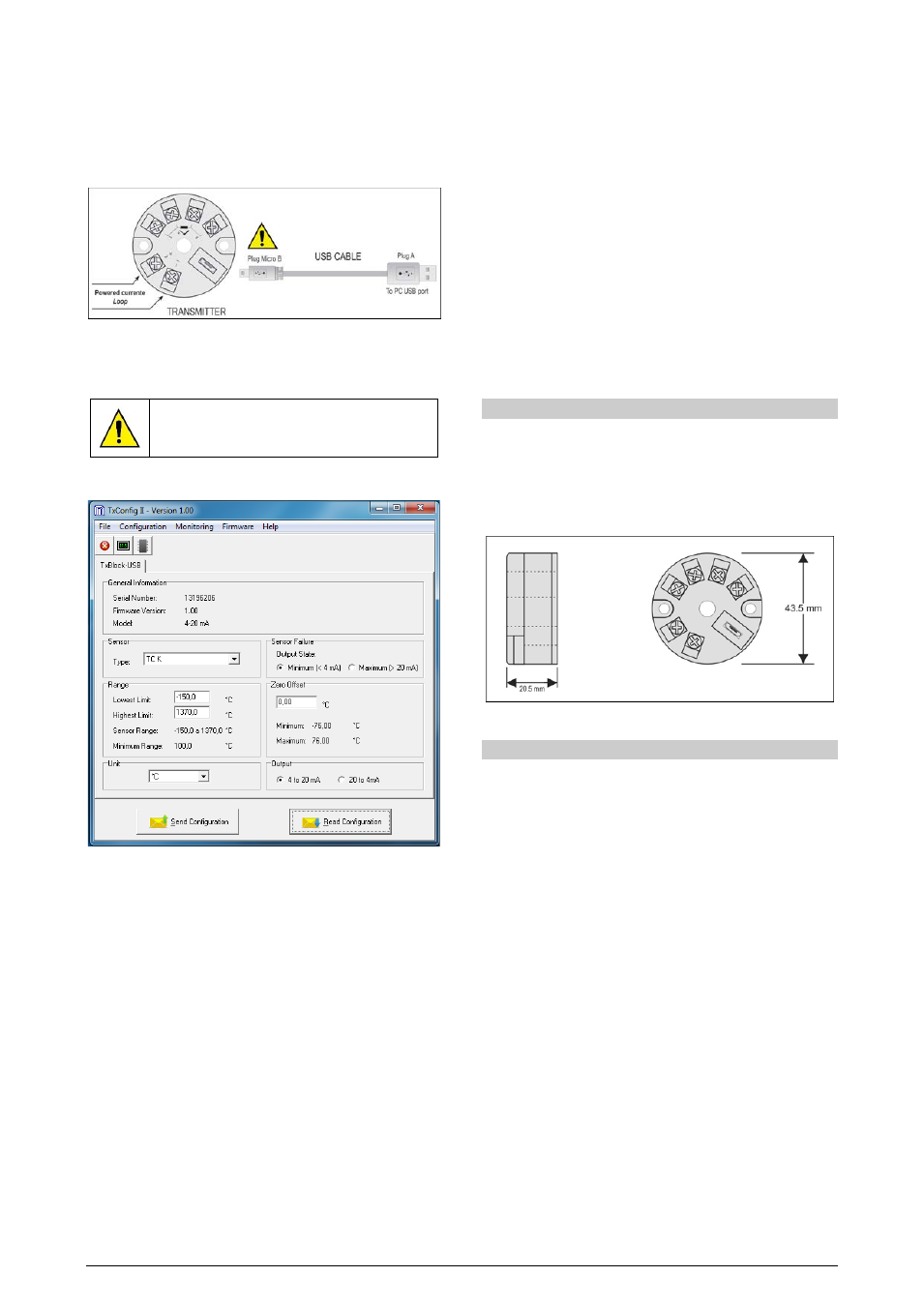

Fig. 2 – USB cable connections – Loop powered

After these connections, the user must run the TxConfig II software

and, if necessary, consult the Help topic to help using the software.

The USB communication port (interface) of the

TxBlock-USB is not electrically insulated from the

transmitter’s input.

SOFTWARE CONFIGURATION:

Fig. 3 – TxConfig II software main screen

The fields in the screen mean:

1. General Information: This field shows information that identifying

the transmitter. This information should be sent to the

manufacturer in an eventual request for technical assistance.

2. Sensor: Select the type of sensor to be used. See Table 1.

3. Measuring Range: Sets de measurement range of the

transmitter.

Lower Range Limit: equivalent temperature for a current of 4

mA.

Upper Range Limit: equivalent temperature for a current of 20

mA.

Sensor Range

The values chosen cannot exceed the range of sensor shown in

this field. See Table 1 of this manual.

Minimum Range

Do not set a lower band (span) that the Minimum Range

indicated below in this same field. See Table 1 of this manual.

4. Sensor Failure: It establishes the output behavior, when the

transmitter indicates a failure:

Minimum: output current goes to < 3.8 mA (down-scale), typically

used for refrigeration.

Maximum: output current goes to > 20.5 mA (up-scale), typically

used for heating.

5. Zero Correction: It corrects small deviations presented in the

transmitter output, for example, when the sensor is replaced.

6. Send Configuration: It applies the new setup. Once sent, the

setup will be immediately adopted by the transmitter.

7. Read Configuration: Reads the current setup in the transmitter

connected. The screen now presents the current setup that may

be changed by the user.

Note: The factory default configuration is:

•

Sensor: Pt100, range 0 to 100 °C, 0 °C zero correction.

•

Sensor failure: upscale (maximum).

Upon purchase order, the user can define a specific setup.

MECHANICAL INSTALLATION

The TxBlock-USB transmitter is suitable to be installed in heads.

Vibrations, moisture and extreme temperatures, electro-magnetic

interference, high voltage and other interferences can permanently

damage the unit, and could cause error in the measured value.

DIMENSIONS:

Fig. 4 – Transmitter dimensions

ELECTRICAL INSTALLATION

• Polyamide enclosure.

• Section of the cable used: 0.14 to 1.5 mm ²

• Recommended torque in the terminal: 0.8 Nm.

RECOMMENDATIONS FOR INSTALLATION

• Sensor signals conductors must go through the plant system

separate from power leads (loop), if possible in grounded

conduits.

• The instruments must be powered from the instrumentation power

supply circuit.

• In control and monitoring applications is essential to consider

what can happen when any part of the system fails.

• It is recommended the use of suppressors in contact coils,

solenoids and any inductive load.