Control terminal wiring, Connection diagram – Beijer Electronics BFI-P2 V1.21 User Manual

Page 22

User Guide Revision 1.12

www.beijerelectronics.com

22

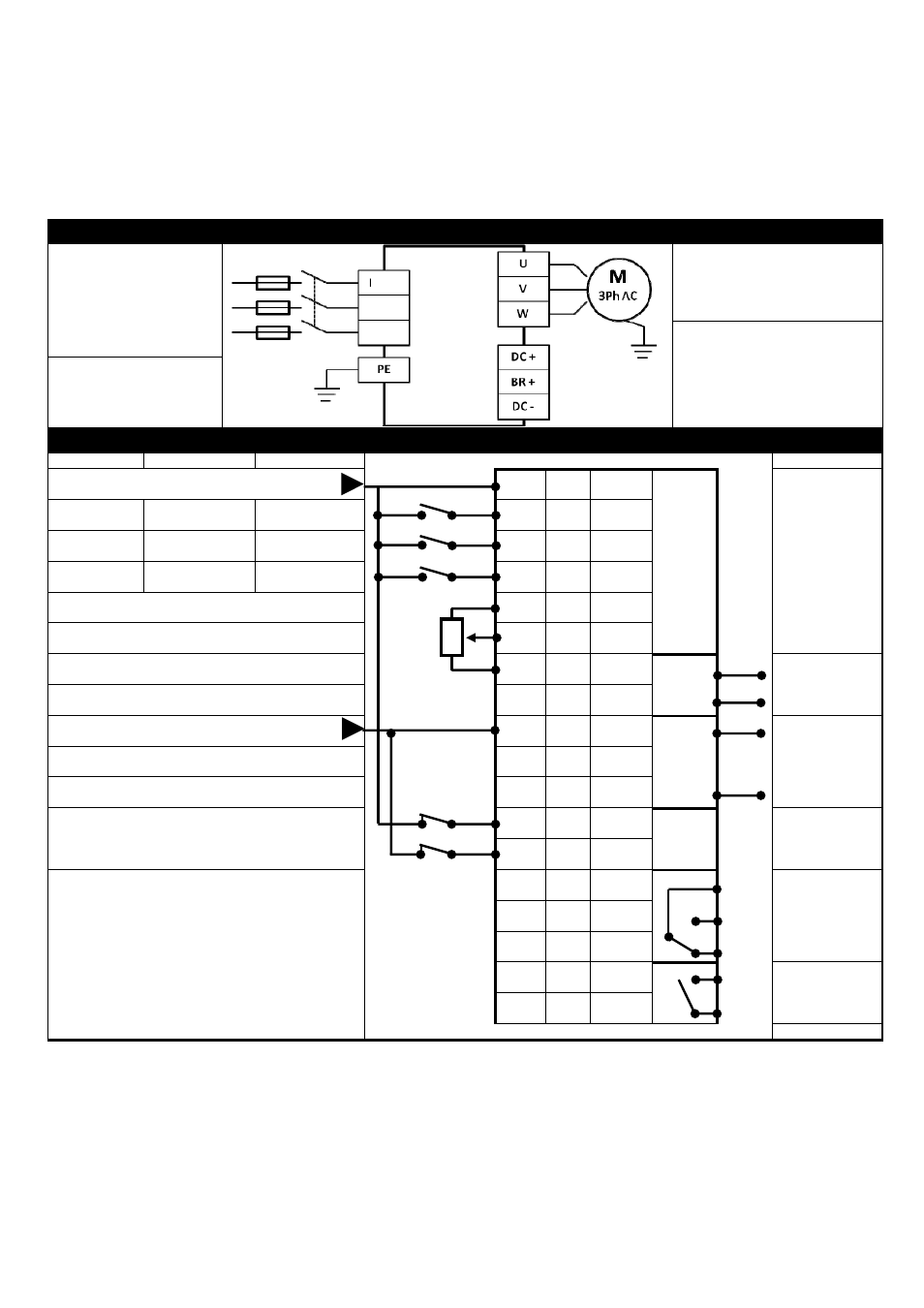

4.8. Control Terminal Wiring

•

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

•

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other

•

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

•

Maximum control terminal tightening torque is 0.5Nm

4.9. Connection Diagram

4.9.1. Power Terminal Designations

Incoming Mains Power Supply

For 1 Phase Supply, connect to

L1/L and L2/N terminals.

For 3 Phase Supply, connect to

L1, L2 & L3 terminals.

Phase sequence is not

important.

Motor Connections

Connect the motor to the U, V & W

terminals.

The motor earth must be connected

to the drive

Optional Brake Resistor & DC Bus

Connections

Where a Brake resistor is used, it

must be connected to the BR+ and

DC+ terminals

Protective Earth / Ground

connection.

The drive must be Earthed /

Grounded

4.9.2. Control Terminal Connections& Factory Settings

Open

Closed

+24V Supply (100mA) / External Input

+24V

1

Digital Input 1

Stop

Run (Enable)

DIN1

2

Digital Input 2

Forward Rotation

Reverse Rotation

DIN2

3

Digital Input 3

Analog Speed Ref

Preset Speed

DIN3

4

Digital Inputs : 8 – 30 Volt DC

+ 10 Volt, 10mA Output

+10V

5

Analog Input 1 (Digital input 4)

AIN1

6

0V

7

0V

Output Speed

Analog Output : 0 – 10 Volt / 4‐20mA, 20mA Max

8

AOUT1

0 Volt Supply / External Input

0V

9

0V

Output Current

Analog Input 2 (Digital input 5)

AIN2

10

Analog Output : 0 – 10 Volt / 4‐20mA, 20mA Max

11

AOUT2

External Hardware Enable Cicuit

STO+

12

STO‐

13

Relay Contacts

250VAC / 30VDC

5A Maximum

14

RL1‐C

Default Function :

Healthy

/ Fault

15

RL1‐NO

16

RL1‐NC

17

RL2‐A

Default Function :

Running

18

RL2‐B

L1 / L

L2 / N

L3