Mechanical installation, General, Before installation – Beijer Electronics BFI-P2 V1.21 User Manual

Page 10: Ul compliant installation, Mechanical dimensions

User Guide Revision 1.12

www.beijerelectronics.com

10

3. Mechanical Installation

3.1. General

•

The Drive should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral

mountingholes or DIN Rail clip (Frame Size 2 only).

•

The Drive must be installed in a pollution degree 1 or 2 environment only.

•

Do not mount flammable material close to the Drive

•

Ensure that the minimum cooling air gaps, as detailed in section 3.5 and 3.7 are left clear

•

Ensure that the ambient temperature range does not exceed the permissible limits for the Drive given in section 10.1

•

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the Drive

3.2. Before Installation

•

Carefully Unpack the Drive and check for any signs of damage. Notify the shipper immediately if any exist.

•

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

•

To prevent accidental damage always store the Drive in its original box until required. Storage should be clean and dry and within the

temperature range –40°C to +60°C

3.3. UL Compliant Installation

Note the following for UL‐compliant installation:

•

For an up to date list of UL compliant products, please refer to UL listing NMMS.E226333

•

The drive can be operated within an ambient temperature range as stated in section 10.1

•

For IP20 & IP40 units, installation is required in a pollution degree 1 environment

•

For IP55 & IP66 units, installation in a pollution degree 2 environment is permissible

•

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections

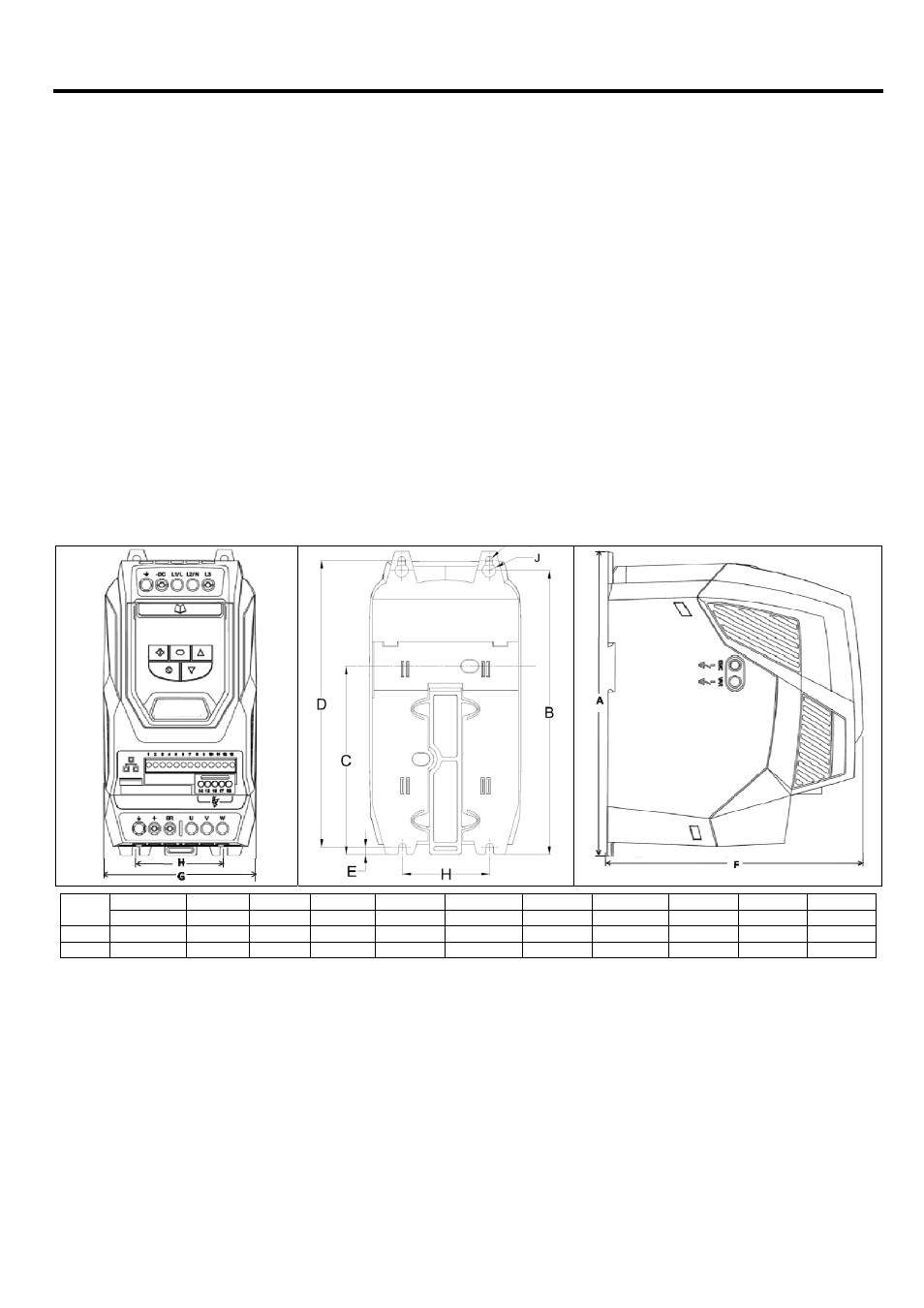

3.4. Mechanical dimensions

3.4.1. IP20 Units

Drive

Size

A / Height

B

C

D

E

F / Depth

G / Width

H

I

J

Weight

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

kg

2

221

207

137

209

5.3

185

112

63

5,5

10

1,8

3

261

246

‐

247

6

205

131

80

5,5

10

3,5

Mounting Bolts

All Frame Sizes :

4 x M4

Tightening Torques

Control Terminal Torque Settings :

All Sizes : 0.8 Nm

Power Terminal Torque Settings :

All Sizes : 1 Nm