Pulsafeeder Isochem RGT IOM User Manual

Page 7

2

Standard Isochem RGT pumps are close-coupled (motor mounted directly to the rear of the

pump) which provides greater assembled strength, enclosure of moving parts, and compact

design. An optional power frame unit is available if required for motor compatibility (see

Appendix G).

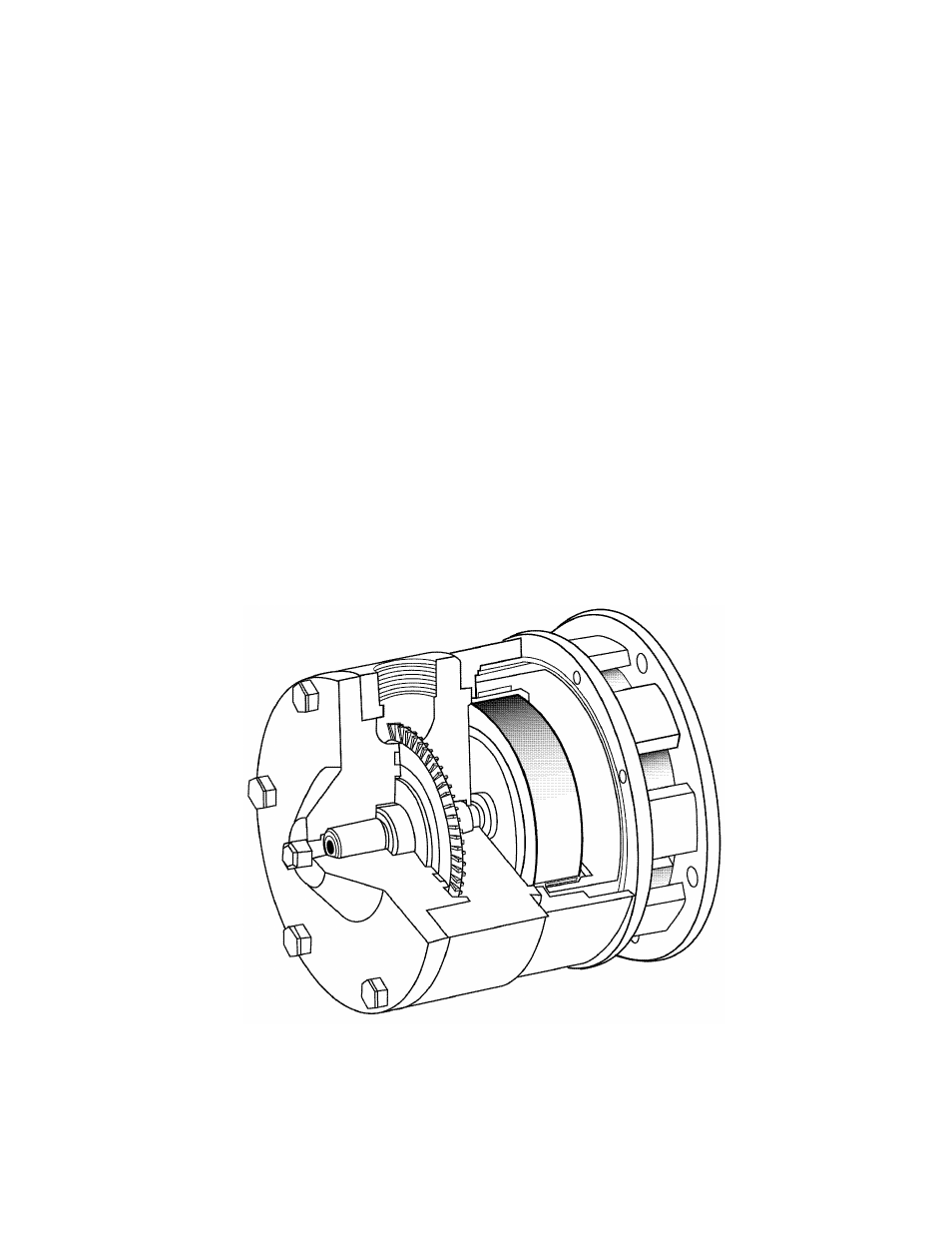

All Isochem pumps transmit rotation from the motor shaft to the impeller shaft by means of a

magnetic drive coupling. An encapsulated driven magnet assembly is installed on the end of the

impeller shaft. It is surrounded by a containment can, which constitutes the rearmost part of the

pump enclosure. A drive magnet installed on the motor shaft rotates around the containment can.

Drive torque is transferred through the containment can by magnetic attraction between the drive

and driven magnet assemblies, causing the pump shaft to rotate. The containment can acts as a

fluid barrier, eliminating the need for a dynamic seal.

The magnetic coupling has an inherent characteristic that causes it to “decouple” if the coupling

torque limit is exceeded. This could happen if a piece of foreign material were to jam the pump

impeller or if unusually high torque was developed for any reason.

The magnets can operate decoupled for short periods of time without losing their magnetic

strength provided that temperature does not exceed specified limits (refer to Appendix A – Pump

Specifications).

The Isochem RGT pump is available in several different materials, and care should be taken that

all pump components (housing, wearplates, bearings) are compatible with the process liquid.

Consult with the factory for applications involving a specific gravity or viscosity greater than that

of water.