Troubleshooting guide – Pulsafeeder Isochem RGT IOM User Manual

Page 29

24

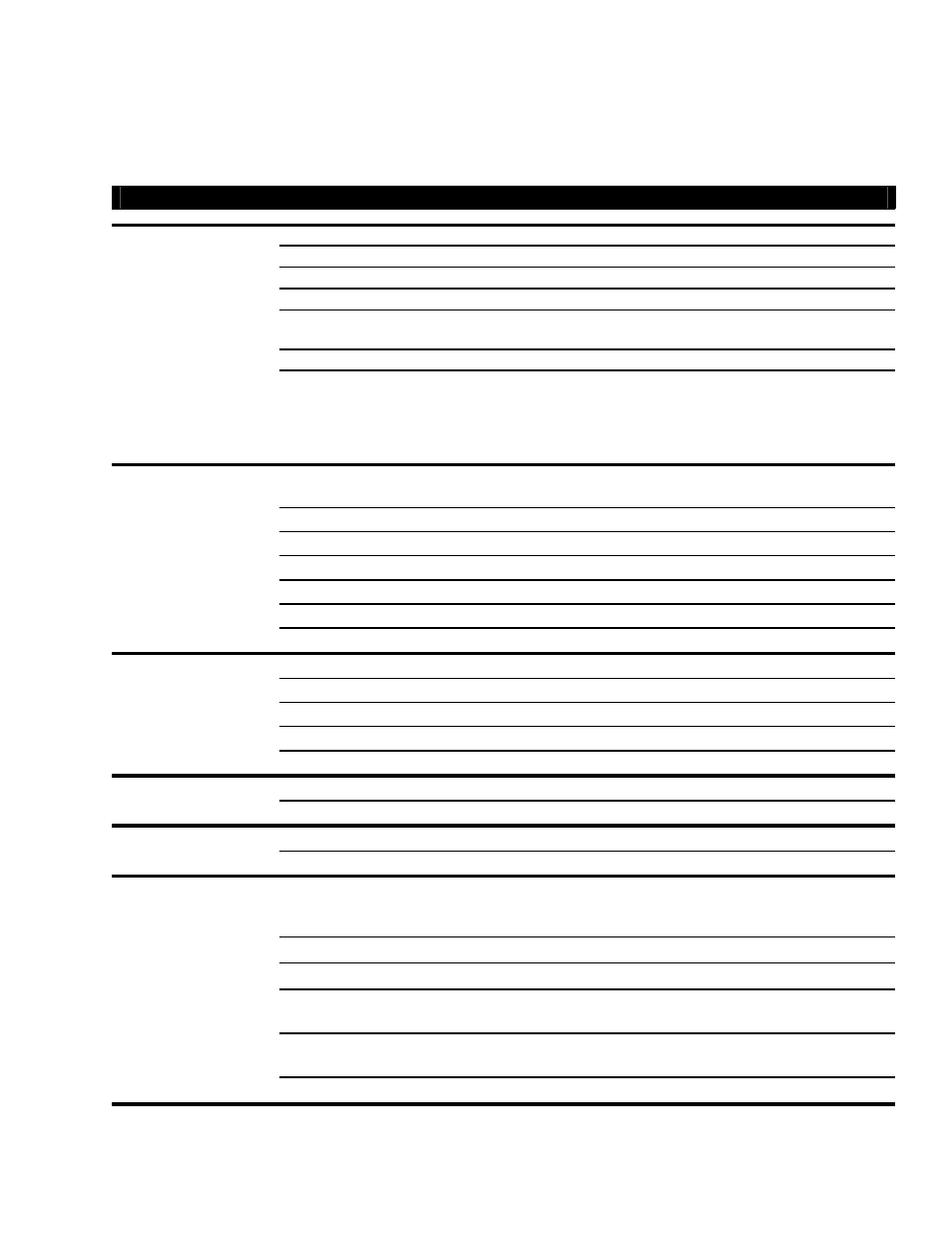

7. Troubleshooting Guide

Symptom

Probable Cause

Remedy

Pump not primed.

Prime pump.

Motor Incorrectly wired.

Check wiring diagram.

Air leak in suction.

Locate and repair.

Rotation direction incorrect.

Reverse rotation.

Suction and/or discharge

valves closed.

Open valves.

Suction lift too high.

Do not exceed vapor pressure of liquid.

No Liquid Delivered

Magnetic coupling decoupled.

Stop motor, eliminate blockage or jamming and restart. If no

blockage exists verify that operating conditions do not exceed

capabilities of the pump. If de-coupling persists upon startup,

a “soft-start” motor starter may be required to accommodate a

fast-starting or oversized motor.

Discharge head higher than

calculated.

Reduce discharge restrictions eg: Open throttle valve.

Air leak in suction.

Repair leak.

Rotational speed incorrect.

Check speed and wiring.

Rotation direction incorrect.

Reverse rotation.

Suction lift too high.

Increase suction pressure.

Impeller or housing worn.

Inspect and repair as required.

Low Liquid Delivery

Wear plates worn.

Inspect and repair as required.

Rotational speed incorrect.

Check Speed.

Air leak in suction.

Repair leak.

Air or gas in liquid.

Eliminate air or gas.

Impeller or Housing worn.

Inspect and repair as required.

Low Discharge

Pressure

Wear plates worn.

Inspect and repair as required.

Air pocket in suction line.

Eliminate pocket.

Pump Gradually

Loses Prime

Air entering suction line.

Keep suction inlet submerged at all times.

Pump worn or damaged.

Inspect and repair as required.

Pump Noisy

Air or gas in liquid.

Eliminate air or gas.

It is normal for motors to feel

hot even when not overloaded.

Check the actual temperature of the motor housing with

suitable instrumentation. Verify the figures with the motor

manufacturer.

Motor wired incorrectly.

Check wiring diagram.

Voltage or frequency low.

Correct condition.

Motor not sized correctly for

the flow.

Higher pressures may require more power than the motor is

capable of.

Heavy or viscous liquid being

pumped.

Pumping fluids heavier or more viscous than water requires a

larger motor.

Motor runs hot or

Overloads

Binding internal pump parts.

Inspect and correct condition.