4 inspection – Pulsafeeder Isochem RGT IOM User Manual

Page 18

13

6.4

Inspection

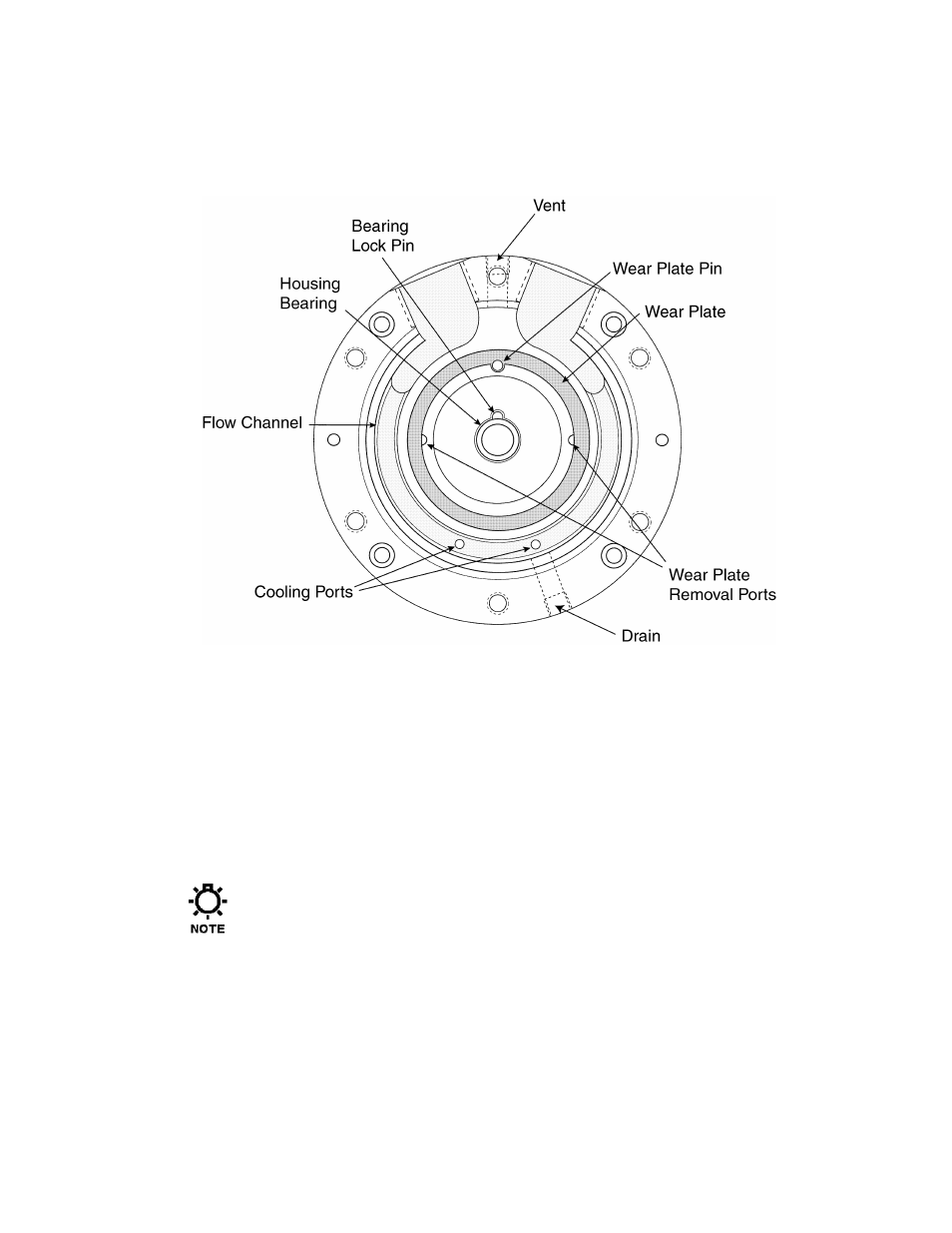

Figure 4

6.4.1

Flow Channel Inspection

The rear housing has two cooling ports located in the flow channel that divert essential

cooling fluid to the magnetic drive chamber. Check and clear these ports if necessary using a

piece of wire or a drill bit of appropriate size

The Cooling Port size in standard pumps is 5/32” (4 mm).

See also other documents in the category Pulsafeeder Pumps:

- Pulsa GLM DM1-6 (30 pages)

- Pulsa GLM DM7 (33 pages)

- Pulsa 340 (24 pages)

- Pulsa Series 200-680C (20 pages)

- Pulsa Series 680 EN (26 pages)

- Pulsar 25H (54 pages)

- Pulsar Shadow (48 pages)

- PulsaPro 900 EN (71 pages)

- Polyfeeder EN (47 pages)

- PULSAlarm (24 pages)

- Eclipse Hypopump (140 pages)

- ECO Series Back Pressure Valve Instructions (1 page)

- ECO Series Relief Valve Instructions (1 page)

- Pulsar Series HypoPump (15 pages)

- Pulsar Series HypoPump2 (27 pages)

- MPC (56 pages)

- MPC Vector (70 pages)

- Pulsa Series Pulsamatic Controls (34 pages)

- Pulsar DLC (120 pages)

- Pulsar DLC XP RC (68 pages)

- Pulsar DLCM (135 pages)

- Pulsar ECA NEMA4X (38 pages)

- Pulsar ECA NEMA7 (23 pages)

- Chem-Tech Series XPV EN (19 pages)

- Chem-Tech Series XP EN (22 pages)

- Chem-Tech Series XP TIMER EN (20 pages)

- Chem-Tech Series Prime Performance EN (12 pages)

- Chem-Tech Series Prime Performance EN (3 pages)

- MEC-O-MATIC VSP Series (8 pages)

- OMNI Series DC7 (34 pages)

- OMNI Series DC2-6 EN (46 pages)

- PULSAtron Series A Plus EN (16 pages)

- PULSAtron Series ET (17 pages)

- PULSAtron Series MP EN (32 pages)

- PULSAtron Series T7 (23 pages)

- Digital Glycol Feeder DGF1 (45 pages)

- Polymer Makedown Automatic Systems EN (15 pages)

- Polymer Makedown Systems EN (11 pages)

- Pre-Engineered Skid Systems (23 pages)